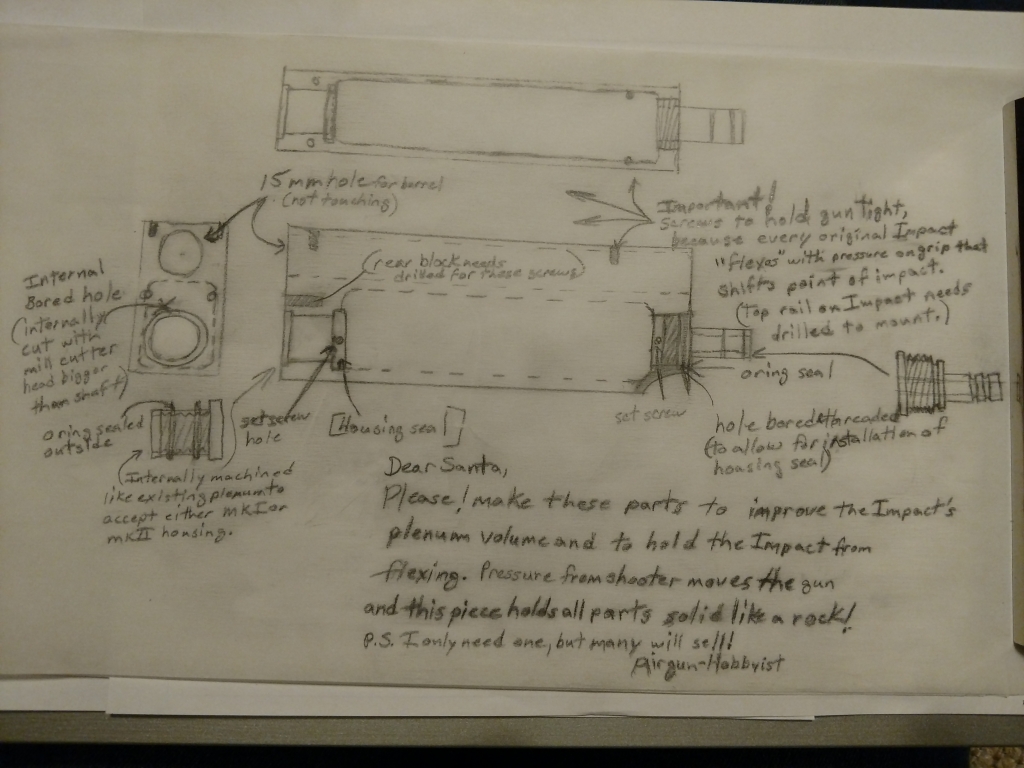

That looks like a good sold piece. Nice machine work too. Since it appears you have access to a machining center to make things, check this crude print out. Feel free to use my design, modify it, mass produce it, or what have you. It essentially makes the back of the Impact one solid piece, once screwed together, and adds plenum volume.

From an engineering point of view, making a pressure tank square in cross section can be dangerous if one doeas not know what one is doing. The forces involved behave quiet different than on a cylindrical tube. The flat walls probably has to be allot thicker compared to a tube. If you ever get one made, you must be sure it can handle the pressure.

Thanks for the education @Tor47 . I will have to rethink how to make the front and back blocks one stout piece. Simply making the bottom of this part radiused, as a cylinder and machining the internal plenum space cylindrical to match would do it I suppose. The concept could be ran on a computer for stresses, made, then pressure tested for sure.

Upvote 0