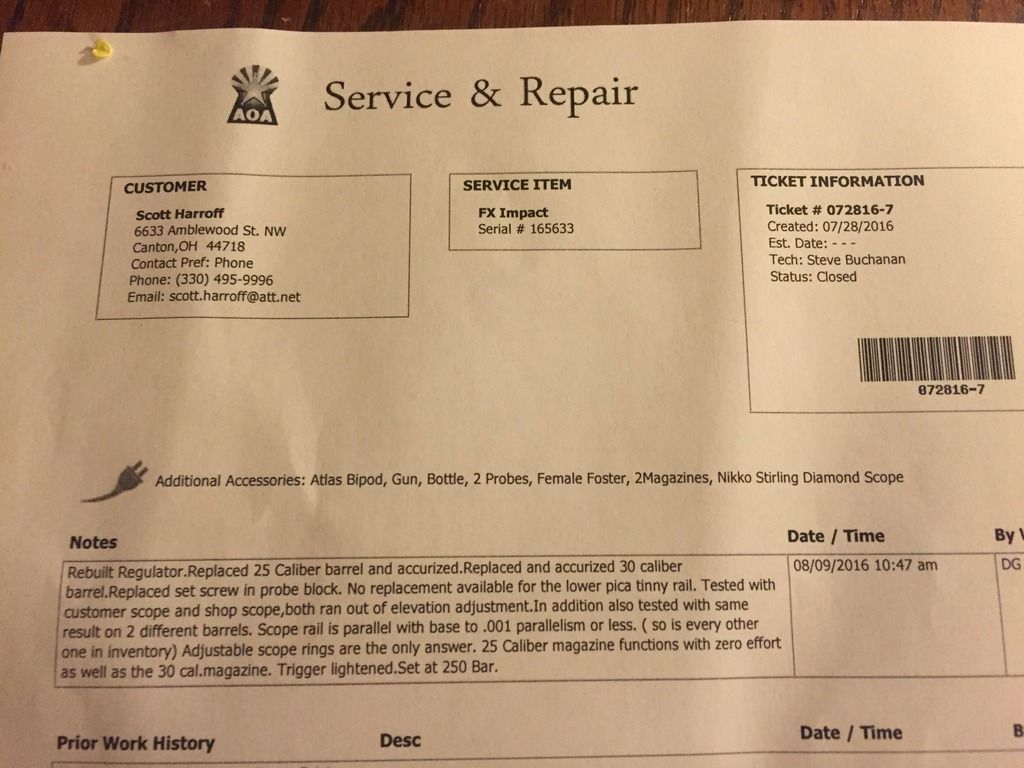

-Pestassassin,"Pestassassin"

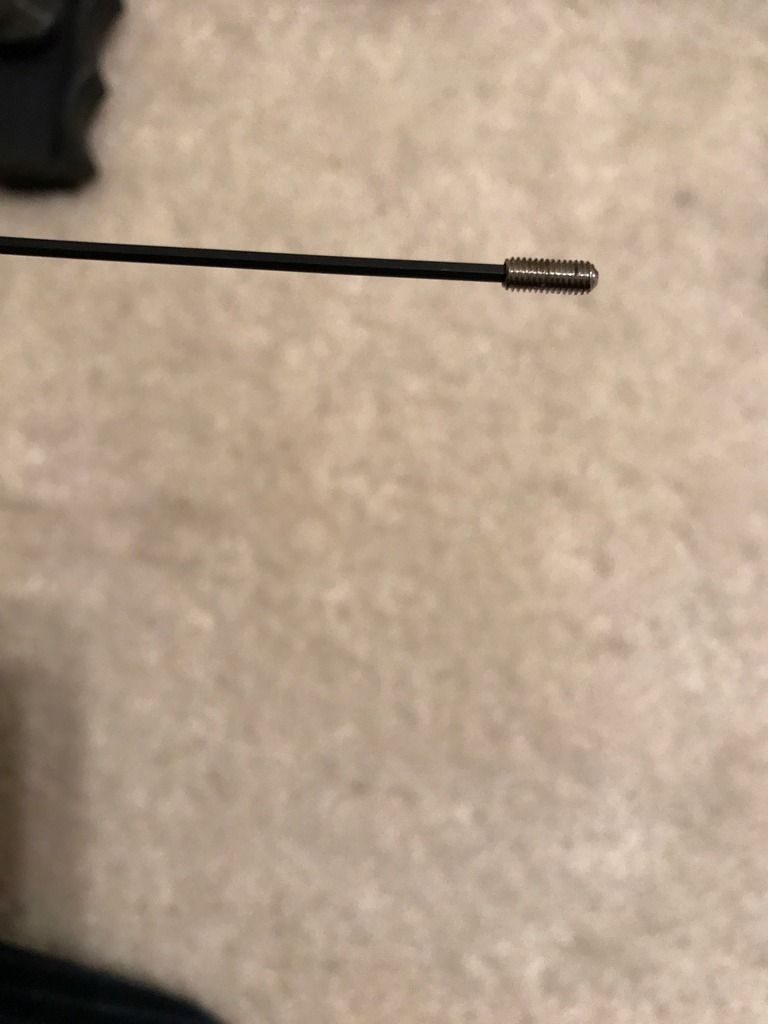

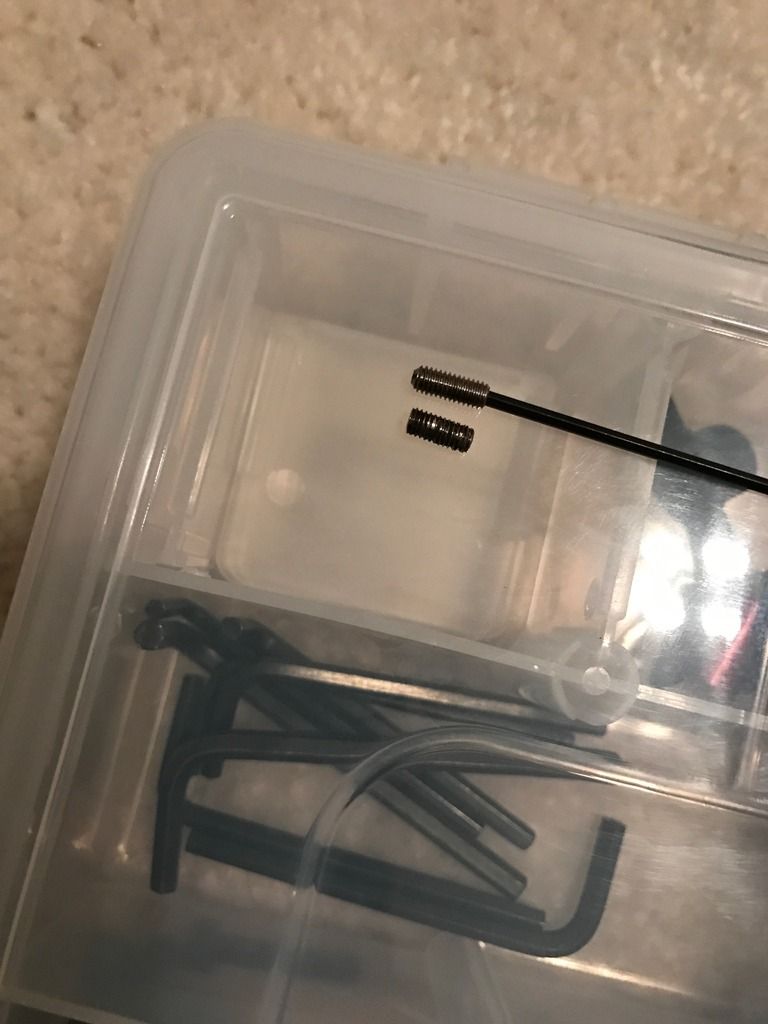

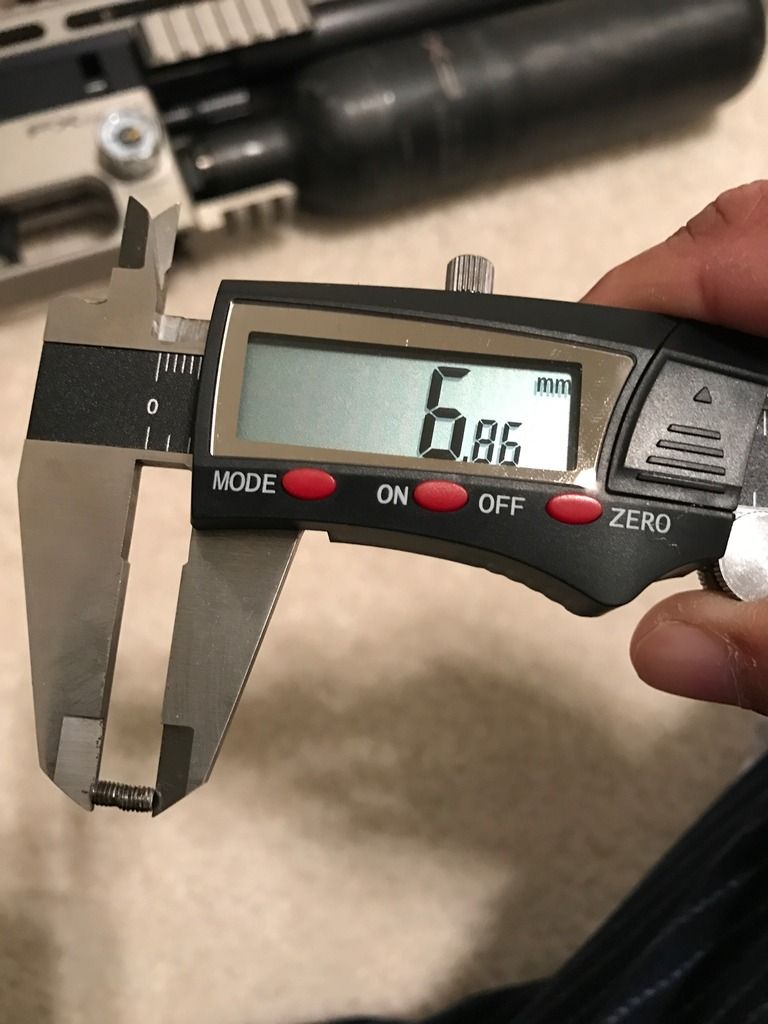

"Jack.K"maybe a temporary fix is to replace the M3x6 grub screw with a M3x8 steel grub screw since the threaded hole on the pellet probe block (feedingpin holder) is deep enough that a longer grub screw can still fit in which will not leave the Hollowed out portion of the screw to take the backward force.

Temporary fix won't work in this situation, as the probe is bent and unusable. On top of that, I don't want a temporary fix. I want to know that this will never happen again.

I was not referring to for you to have a termporary fix for your gun. You should ship it back to get it service. I was mainly saying for the other Impact owners out there to consider the M3x8 steel grub screw as a temporary fix until FX comes up with a solution for this safety issue.

Upvote 0