7,62 / .30 caliber hits hard I heard...

Hello there everyone!

I'm new here folks, just joined a couple of hours ago... I go by the name of Triglav and I'm just an average Joe, no-one special and an airgun enthusiast.

I own a few of these things, 3 air rifles chambered in .177 and one in .22 - that one being the Gamo Black Bear in 5,5 mm.

Now, there's an air rifle, that's been in my sights, or well on my wishlist for quite a while now - the one and only Hatsan model 130S, chambered in .30 caliber (7,62 mm).

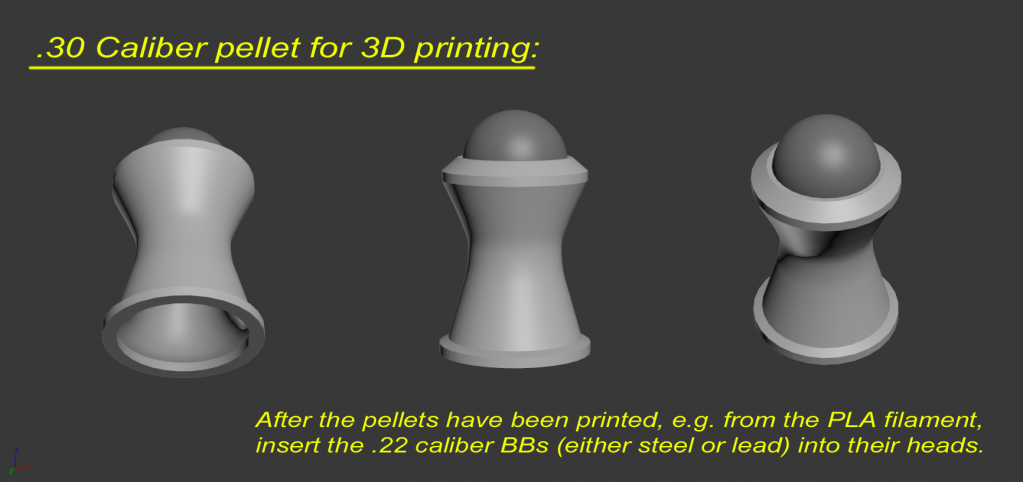

The thing is, before I make the final decision to go and get this thing from an airgun store on the other side of my country, I'd like to know, how this thing would perform with

rather lightweight ammunition for a .30 cal, such would be these 3D printed pellet bodies with .22 Slugs or BBs stuck into the hollows of their head. I reckon they'll fly

really fast due to their lighter weight; The standard .30 caliber pellet from JSB weighs 2,9 grams / 44.75 grains and flies at 550 FPS on average and I'm sure that these pellets,

that I've designed would fly much faster.

I'm giving away free 3D models here, of these .30 caliber pellets, that I've designed and which can of course be 3D printed from either PLA (the cheapest material),

ABS (probably not the best option out there) or even Nylon or anything else in between. I've personally never handled a 3D printer before - I'm planning on getting one

someday, but right now I don't really have a serious need for one and with this said I'd like someone to 3D print a couple of these and test them. I've also designed other

3D models for printing in the past, everything from suppressor baffles to mounting systems for optics and even chassis for AR styled stocks and so far all of these designs/

3D models of mine have been printed properly by my friends to whom I've given them, true to their model dimensions.

If anyone here has got the time and will to print a couple of these pellets and test them through their .30 cal airguns (preferably through the Hatsan 130S/ 135 - .30) for both

accuracy and velocity, I would appreciate it a lot! Oh, and don't forget to weight them too.

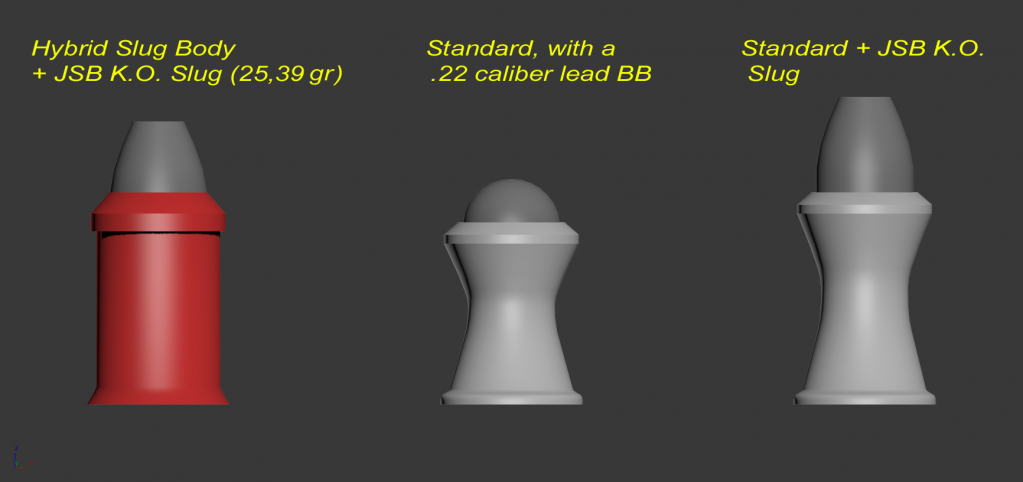

So, all you're going to have to do is to print them, well obviously... and then you'll have to either shove or glue a .22 cal BB or a JSB Knockout SLUG into the place of their

heads and that will be it (Check the image, that I've attached to this post). While I was making these models I had assumed, that without the BBs or Slugs, the pellets would

simply be too light and without a proper balancing point, so I've thought of BB/Slug tips. BTW, the pellet with the BB is roughly 10 mm tall without the BB and the other,

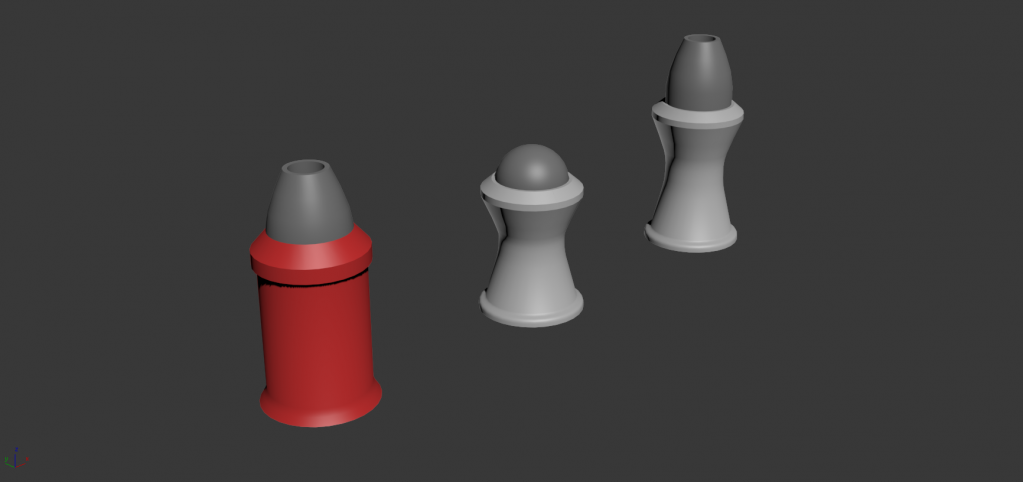

classic dome shaped pellet with a JSB KO Slug in its head is 12 milimeters tall. Same goes for the hybrid slug body of the red pellet - check the attached image (I just assigned

a red colour to it, when it's going to get printed it'll be of the filament's colour).

View attachment 3D_Pellets_762.1624502336.zip

View attachment 3D_Pellets_762.1624502336.zip

Once again, I'd be delighted to see how these'll perform and of course I'd also like to give a big thanks to all of you folks reading this.

The files and images are in the zip file.

- Triglav

Hello there everyone!

I'm new here folks, just joined a couple of hours ago... I go by the name of Triglav and I'm just an average Joe, no-one special and an airgun enthusiast.

I own a few of these things, 3 air rifles chambered in .177 and one in .22 - that one being the Gamo Black Bear in 5,5 mm.

Now, there's an air rifle, that's been in my sights, or well on my wishlist for quite a while now - the one and only Hatsan model 130S, chambered in .30 caliber (7,62 mm).

The thing is, before I make the final decision to go and get this thing from an airgun store on the other side of my country, I'd like to know, how this thing would perform with

rather lightweight ammunition for a .30 cal, such would be these 3D printed pellet bodies with .22 Slugs or BBs stuck into the hollows of their head. I reckon they'll fly

really fast due to their lighter weight; The standard .30 caliber pellet from JSB weighs 2,9 grams / 44.75 grains and flies at 550 FPS on average and I'm sure that these pellets,

that I've designed would fly much faster.

I'm giving away free 3D models here, of these .30 caliber pellets, that I've designed and which can of course be 3D printed from either PLA (the cheapest material),

ABS (probably not the best option out there) or even Nylon or anything else in between. I've personally never handled a 3D printer before - I'm planning on getting one

someday, but right now I don't really have a serious need for one and with this said I'd like someone to 3D print a couple of these and test them. I've also designed other

3D models for printing in the past, everything from suppressor baffles to mounting systems for optics and even chassis for AR styled stocks and so far all of these designs/

3D models of mine have been printed properly by my friends to whom I've given them, true to their model dimensions.

If anyone here has got the time and will to print a couple of these pellets and test them through their .30 cal airguns (preferably through the Hatsan 130S/ 135 - .30) for both

accuracy and velocity, I would appreciate it a lot! Oh, and don't forget to weight them too.

So, all you're going to have to do is to print them, well obviously... and then you'll have to either shove or glue a .22 cal BB or a JSB Knockout SLUG into the place of their

heads and that will be it (Check the image, that I've attached to this post). While I was making these models I had assumed, that without the BBs or Slugs, the pellets would

simply be too light and without a proper balancing point, so I've thought of BB/Slug tips. BTW, the pellet with the BB is roughly 10 mm tall without the BB and the other,

classic dome shaped pellet with a JSB KO Slug in its head is 12 milimeters tall. Same goes for the hybrid slug body of the red pellet - check the attached image (I just assigned

a red colour to it, when it's going to get printed it'll be of the filament's colour).

Once again, I'd be delighted to see how these'll perform and of course I'd also like to give a big thanks to all of you folks reading this.

The files and images are in the zip file.

- Triglav