So I am 200 shots into my second tin and that annoying spring buzz is still bugging me. No signs of letting up. Enough I say! Down to the shop I go. I use my special process screw heat transfer method and remove them. Then going by memory on that European dudes YouTube disassembly video it's off to the races! I used my best fitting Brownells driver set for practically zero screw damage. Just a little bluing rub in the slots. I will admit this tear down is a little more complicated than the D34's, but I had no problems taking my time. I could not bear the thought of using a cloth covered wrench to break the threaded end block free. I had an aluminum short bar and leather to keep it in place.

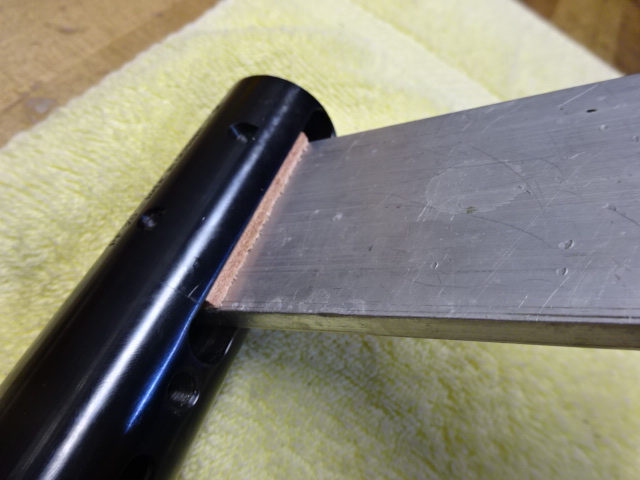

I also used the suggested sleeve method over the internal threads to protect the seal when entering the tube. Great tip!! Thanks.

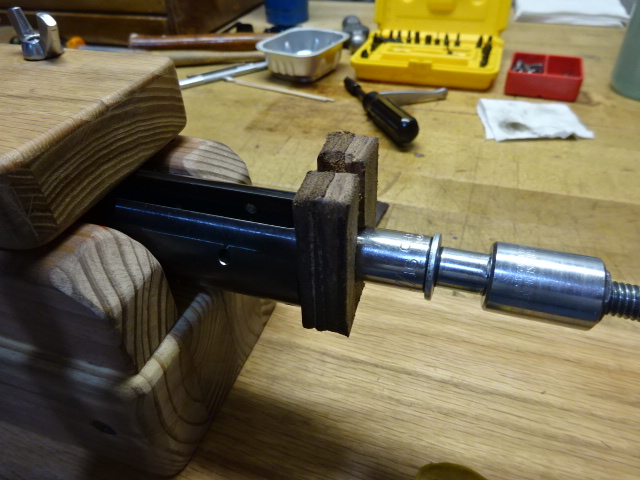

My home made spring compressor was perfect for the job with no modifications needed. I replaced the factory guts with Vortek components smearing on all the grease in the little supplied cup. No question with over an inch of spring hanging out a compressor was a must. Reassembly was relatively easy. I put a dab of grease on that little hex nut for the rear trigger guard screw to keep it in place. It fell out and I almost re assembled with it laying on the towel out of sight. I put a light epoxy film on the screw cap under sides and tightened them up.

30 minutes later after cleaning up and putting tools away...time for a test. Quiet with no more buzzing..NICE. Just a no buzz or vibration "thook" sound like my quiet 34 (one now) has. The Vortex scope while still in the RWS mount went right back on. It took 35-40 shots for the whole system to settle down and pellets returning to the prior impact point. Still nice tight little clusters and QUIET!!!

I will get another Vortek spring and seal ordered to have on hand.

I also used the suggested sleeve method over the internal threads to protect the seal when entering the tube. Great tip!! Thanks.

My home made spring compressor was perfect for the job with no modifications needed. I replaced the factory guts with Vortek components smearing on all the grease in the little supplied cup. No question with over an inch of spring hanging out a compressor was a must. Reassembly was relatively easy. I put a dab of grease on that little hex nut for the rear trigger guard screw to keep it in place. It fell out and I almost re assembled with it laying on the towel out of sight. I put a light epoxy film on the screw cap under sides and tightened them up.

30 minutes later after cleaning up and putting tools away...time for a test. Quiet with no more buzzing..NICE. Just a no buzz or vibration "thook" sound like my quiet 34 (one now) has. The Vortex scope while still in the RWS mount went right back on. It took 35-40 shots for the whole system to settle down and pellets returning to the prior impact point. Still nice tight little clusters and QUIET!!!

I will get another Vortek spring and seal ordered to have on hand.