TeslaToTheMoon

Destructive testing can be very informative, providing it is not involuntary. Your air dump from the Huben piston sounds like a useful test, if it is repeatable. Although I am not sure it is realistic. If you design a vehicle to be crash safe at 100 MPH it may be to heavy to be practical in ordinary use.

That said, it would be interesting to know if the muffler I designed would stand up to such a valve dump. I suspect not. I welcome you to try it after you evaluate it for sound and groups size and shift..

I do not design for such drastic system failures, because everyone wants "light weight". My design approach does consider the average pressure down the barrel to produce the known FPE. I would prefer to know the muzzle pressure, but that actually comes up in an unregulated PCP as the air tank pressure drops, via longer valve duration.

I have attached a screenshot of a spreadsheet that calculates the average bore pressure required to produce a given FPE, with a given caliber and barrel length. I add a factor for pellet friction, that is assumed, rather than measured - in this case. For a Huben pistol to make 80 FPE from its 8" barrel requires an average bore pressure of around 2500 PSI. The muzzle pressure would be perhaps half that if the air tank is at 4500 PSI. When the air tank pressure has dropped to 2500 PSI, the valve would have to stay open until the pellet left the muzzle, or you won't get 80 FPE.

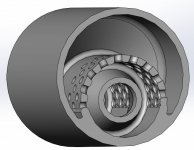

Even though a muffler is an open system, I consider the bulk pressure in the first and perhaps second expansion chambers, based on their volumes. Then I apply that pressure to the casing of the muffler and see if this is below the rated pressure for that material, at that thickness, at at that radius.

You asked about making your muffler stronger. If it seems impossible to make that shape strong enough to not blow up under a valve dump, while maintaining acceptable sound suppression, then design it to be "fail safe". In other words leave a weaker area that will fail first, in a direction that is least likely to cause injury or damage.

I think the large flat sides on your muffler see massive bending stresses that an equivalent round section would not see. I am not about to suggest you abandon your chamfered rectangle design. But adding generous fillets to the inside corners between flats might help make the structure look more round to the air inside.

I often taper the wall thickness of my outer casings, because it is the rear near the barrel muzzle that see the highest air pressure. The rear also sees the greatest bending moment, due to the frontal weight. By thinning out the walls near the front, that material adds less bending stress to the rear. And it should be able to handle reduced air pressure, based on the pressure gradient across the device.

From the locks of it, failure started at the rear of your muffler, in the far lower wall opposite the thread insert. It also looks like the casing failed in tension, front to rear. High speed video would help here.

I think that the degree of foam infill between the back of your muffler and the first air stripper is effectively reducing the instantaneous expansion volume where it is desperately needed. Now, with a valve dump, perhaps any reasonable size expansion volume would fill up, and then the structure see unusually high air pressure, between air tank pressure and whatever pressure reduction occurs due to flow down the baffle bores.

View attachment 387451 F