You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HP3 main valve stuck (Omega 75 cf tank)

- Thread starter Twinkees_n_Pb

- Start date

Wow, man, I have no clue (pipe wrench may be too harsh). I'm definitely curious what others advise.

Upvote 0

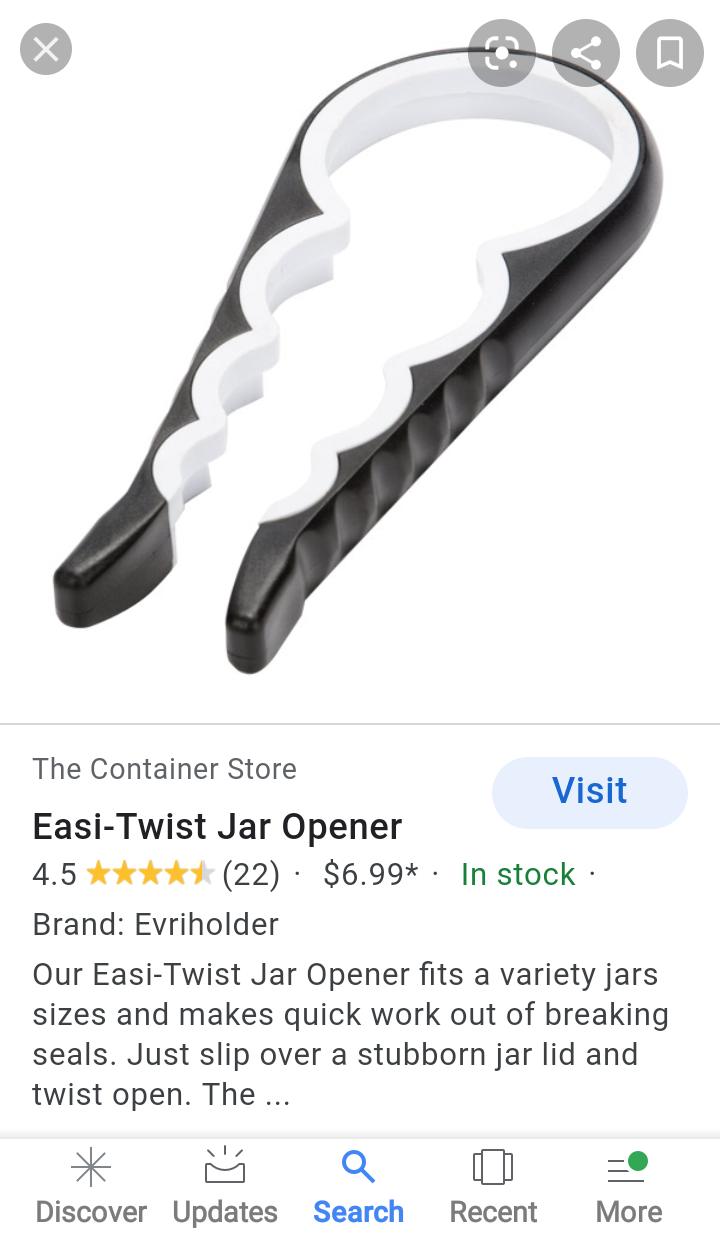

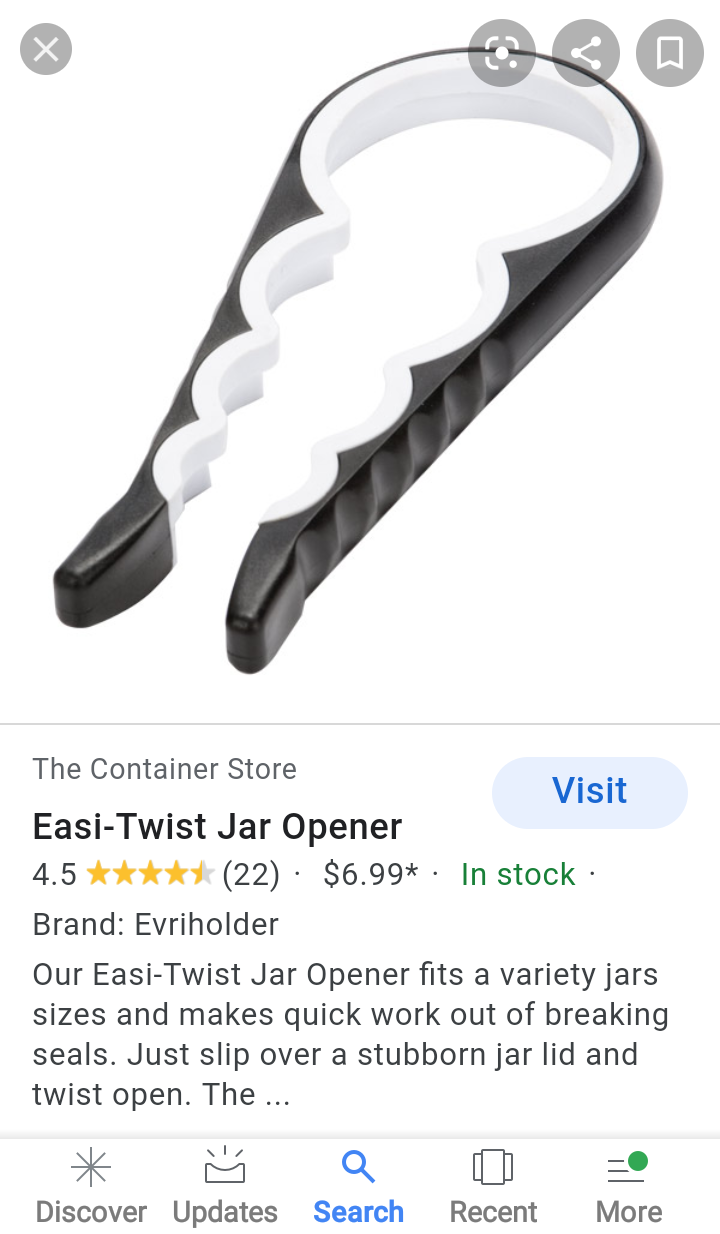

Try tightening it more (closed position) then turn to open the valve. Eat your spinach.

Check your local dollar store or Wal-Mart.

Check your local dollar store or Wal-Mart.

Upvote 0

Thanks @odoyle. Lol. I just can't imagine it being so tight from when I was operating the valve (open/closing) with ease month ago. I made sure to not over-tighten it also. Anyway at this point am leaving it out in the living room /temps to see if it will help (as perhaps the cold air in the closet contracted the orings/internals). No idea at this point... will let it sit for 24hrs before your jar opener on it.

Upvote 0

Any chance you need to push down on the knob and turn at the same time? Some firefighter SCBA’s have that safety feature, I know your unit doesn’t have a firefighter scba valve but thought I would throw it out there...

Upvote 0

Twinkees_n_ Pb,

I've had similar problems with my new Omega Patriot 75 cf tank and HP3.

Here's a timeline of my issues:

3-5-21 Received new Omega Patriot 75 cf tank and HP3. Would not take air from local dive shop.

3-15-21 Received 2nd HP3. Filled normally from local dive shop, and operated fine.

3-25-21 HP3 #2 failed after 10 days of normal use. Now when I open the large valve on top, no air is released. Small pressure gauge still shows 4000psi in tank. Even when large valve at top is fully opened, no air is released through Foster QD connector.

3-29-21 Received 3rd(!) HP3. This one filled normally from local dive shop, and has operated normally to date.

AOA told me there's a gasket/seal that can move and cover ports inside HP3. Apparently, I was unlucky enough to get 2 bad HP3s.

I really like these HP3 valves, when they work. Good luck with your HP3.

FX Dream-Tac Compact in .22

I've had similar problems with my new Omega Patriot 75 cf tank and HP3.

Here's a timeline of my issues:

3-5-21 Received new Omega Patriot 75 cf tank and HP3. Would not take air from local dive shop.

3-15-21 Received 2nd HP3. Filled normally from local dive shop, and operated fine.

3-25-21 HP3 #2 failed after 10 days of normal use. Now when I open the large valve on top, no air is released. Small pressure gauge still shows 4000psi in tank. Even when large valve at top is fully opened, no air is released through Foster QD connector.

3-29-21 Received 3rd(!) HP3. This one filled normally from local dive shop, and has operated normally to date.

AOA told me there's a gasket/seal that can move and cover ports inside HP3. Apparently, I was unlucky enough to get 2 bad HP3s.

I really like these HP3 valves, when they work. Good luck with your HP3.

FX Dream-Tac Compact in .22

Upvote 0

Thanks for sharing that story @bigdaddy0004 Ugh kinda sucks to think may have to send it back. Hopefully just a bad batch, as doesn't sound like these new valves are reliable. I like them for sure, but if turns out they just suck then will move on to next brand. Anyway will give AoA a call before I put a lid opener on it.

@aimright thanks for the idea, however these are not that push-knob types...unless am missing something. Thanks again.

@aimright thanks for the idea, however these are not that push-knob types...unless am missing something. Thanks again.

Upvote 0

Just to throw this out.

I bought my 66 cu-ft SCBA tank from Joe Brancato (714-907-0067) owner of http://experthpa.com/cart/cart.php.

I got my tank, used. Joe calls it a "Hammerhead". His tanks seem to be named after sharks. It has served me well - never have had an issue with it.

I may one day contact him again and buy his "Great White" 97 cu-ft tank, but I'm still happy with the Hammerhead. And I don't need to take it anywhere to get it filled, since I bought an Air Venturi 4500 HPA compressor. That sure is convenient.

I bought my 66 cu-ft SCBA tank from Joe Brancato (714-907-0067) owner of http://experthpa.com/cart/cart.php.

I got my tank, used. Joe calls it a "Hammerhead". His tanks seem to be named after sharks. It has served me well - never have had an issue with it.

I may one day contact him again and buy his "Great White" 97 cu-ft tank, but I'm still happy with the Hammerhead. And I don't need to take it anywhere to get it filled, since I bought an Air Venturi 4500 HPA compressor. That sure is convenient.

Upvote 0

Try tightening it more (closed position) then turn to open the valve. Eat your spinach.

Check your local dollar store or Wal-Mart.

Hey, odoyle, you reckon that would be better than a small pipe wrench?

Upvote 0

Upvote 0

@Twinkees_n_Pb

That really is disappointing. I'd call AOA and get them to send you another new, complete HP3. They should overnight it to you while you deal with getting the air out of your tank. The replacement HP3(s) had prepaid return shipping label(s) included.

I also had over 4000psi still in the tank that I couldn't get out. They (AOA) had me carefully unscrew the small gauge, just enough to hear air leaking out. It took several hours to get it completely drained. Then it was an easy matter to unscrew the complete HP3 for the return shipping to AOA.

If my 3rd HP3 fails, I'm going to ask for a refund and seek out other alternatives. 3 strikes and I'm out.

Good luck again.

That really is disappointing. I'd call AOA and get them to send you another new, complete HP3. They should overnight it to you while you deal with getting the air out of your tank. The replacement HP3(s) had prepaid return shipping label(s) included.

I also had over 4000psi still in the tank that I couldn't get out. They (AOA) had me carefully unscrew the small gauge, just enough to hear air leaking out. It took several hours to get it completely drained. Then it was an easy matter to unscrew the complete HP3 for the return shipping to AOA.

If my 3rd HP3 fails, I'm going to ask for a refund and seek out other alternatives. 3 strikes and I'm out.

Good luck again.

Upvote 0

Thanks again. HP3 valve is on its way back to AoA. (Thank you, to the guys at AoA for understanding.) It me about 2.5hrs to drain 4200psi; same method. After that the whole hp3 unit screws out easily as you've experienced.

Upvote 0

Standard SCBA valves are the BEST & most RELIABLE! That's because firefighter's lives depend on them working easily & working every time. An SCBA valve can be found for for $30 or less.

Upvote 0

I think I would just go to a standard SCBA and CGA347 setup like Gerry said. Most reliable way IMO.

Upvote 0

Standard SCBA valves are the BEST & most RELIABLE! That's because firefighter's lives depend on them working easily & working every time. An SCBA valve can be found for for $30 or less.

SCUBA valves like the 300 DIN types that many airgun supply retailers market have the same safety responsibilities as the fireman types. How would you like to have a malfunction 40 metres underwater? In my country,( Australia), emergency workers only use DIN 300 valves on their SCBA apparatus. CGA346-347 like 110-volt domestic power is just another of the many peculiarities that separate the USA from the rest of the world.

Upvote 0

All good points guys. Thanks for the insight. Totally see that... failure is not an option. Outside of critical needs as you've all stated, would also suck if I drove an hour or more to a range/event only to find myself with a stuck valve. Though am of the mindset 2 is 1, 1 is none... normally travel with 2 of everything I need thats mission critical. That said the 2nd guppy-size bottle I'll be adding to my bag will be with a regular valve as you all are suggesting.

Upvote 0

Standard SCBA valves are the BEST & most RELIABLE! That's because firefighter's lives depend on them working easily & working every time. An SCBA valve can be found for for $30 or less.

SCUBA valves like the 300 DIN types that many airgun supply retailers market have the same safety responsibilities as the fireman types. How would you like to have a malfunction 40 metres underwater? In my country,( Australia), emergency workers only use DIN 300 valves on their SCBA apparatus. CGA346-347 like 110-volt domestic power is just another of the many peculiarities that separate the USA from the rest of the world.

Standard 300 DIN is not rated to 4500psi. Most SCUBA tanks in the usa are 3000psi and use K-valves. SCBA in USA are 4500psi standard but some FD now are going to 6,000psi systems now. We use CGA 347 because we use higher pressure equipment in USA.

Upvote 0

@ Kevin

Standard 300 DIN is not rated to 4500psi. Most SCUBA tanks in the usa are 3000psi and use K-valves. SCBA in USA are 4500psi standard but some FD now are going to 6,000psi systems now. We use CGA 347 because we use higher pressure equipment in USA.

Standard DIN 300 is suitable for SCUBA or SCBA for 300 or 310bar tanks. There is no difference between a 300 BAR SCBA bottle and a 4500 psi bottle, they are both capable of safely holding more than double their rating. 10 BAR difference doesn't warrant a different construction to do the same job. As for valves, there is probably no difference in the construction of any of the valves apart from the different interfaces that comply with the type and pressure of the tank that it is to be matched to. You are correct in stating that K valves are only rated for pressures up to 3000 psi. DIN 200 can also be used for those bottles and is superior in safety and ease of use. SCUBA bottles are only rated to 3000 or 3300 PSI in the USA. DIN300 is recommended for anything above 3000 The rest of the world allows steel tanks to be rated up to 300 BAR or 4351 PSI and the law allows them to be overfilled by 10%. The reason that you don't see them over there is another oddity of your D.O.T system. DIN 200-300 are basically the same valves as CGA 346-347. Only the interface is different. Some SCBA bottles are only rated for 2200 PSI, that's where CGA 346 is used, the same goes for over here where DIN 200 is used. To claim that only the USA uses 4500 PSI SCBA and that they are going to use the same interface if and when they switch to 6000 PSI are both fallacies. My rejection of the claim that one type of valve is better than another, stands. In the real world, SCUBA equipment has to operate in a much harsher environment and has the same life depending responsibility as the SCBA.

Standard 300 DIN is not rated to 4500psi. Most SCUBA tanks in the usa are 3000psi and use K-valves. SCBA in USA are 4500psi standard but some FD now are going to 6,000psi systems now. We use CGA 347 because we use higher pressure equipment in USA.

Standard DIN 300 is suitable for SCUBA or SCBA for 300 or 310bar tanks. There is no difference between a 300 BAR SCBA bottle and a 4500 psi bottle, they are both capable of safely holding more than double their rating. 10 BAR difference doesn't warrant a different construction to do the same job. As for valves, there is probably no difference in the construction of any of the valves apart from the different interfaces that comply with the type and pressure of the tank that it is to be matched to. You are correct in stating that K valves are only rated for pressures up to 3000 psi. DIN 200 can also be used for those bottles and is superior in safety and ease of use. SCUBA bottles are only rated to 3000 or 3300 PSI in the USA. DIN300 is recommended for anything above 3000 The rest of the world allows steel tanks to be rated up to 300 BAR or 4351 PSI and the law allows them to be overfilled by 10%. The reason that you don't see them over there is another oddity of your D.O.T system. DIN 200-300 are basically the same valves as CGA 346-347. Only the interface is different. Some SCBA bottles are only rated for 2200 PSI, that's where CGA 346 is used, the same goes for over here where DIN 200 is used. To claim that only the USA uses 4500 PSI SCBA and that they are going to use the same interface if and when they switch to 6000 PSI are both fallacies. My rejection of the claim that one type of valve is better than another, stands. In the real world, SCUBA equipment has to operate in a much harsher environment and has the same life depending responsibility as the SCBA.

Upvote 0