Hey Guys,

This is the second part of installing QF's on a Rapid MKII

For Part 1

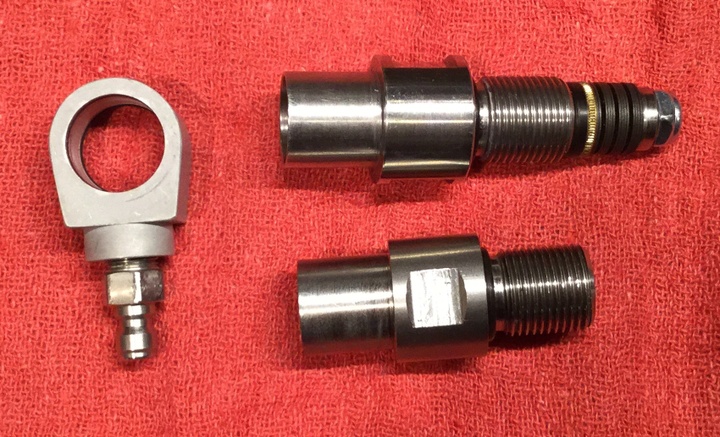

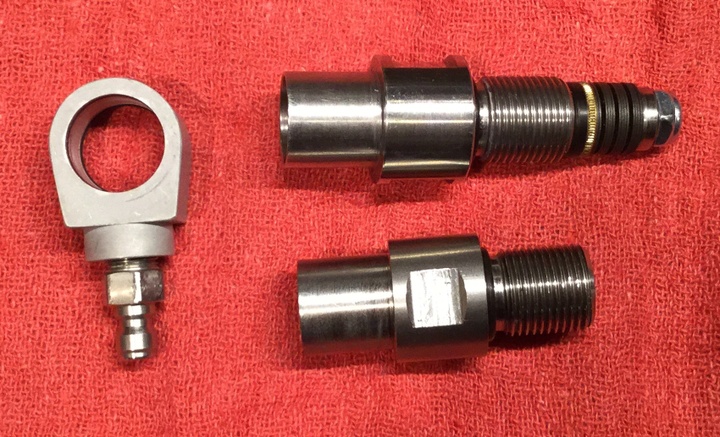

Now on to the RAW QF kit. It replaces your Reg adapter. It comes with a new reg/bottle adapter and banjo fitting with gauge and QF nipple.

This one I had to make a custom banjo fitting.

Since the stock one with the Gauge would not fit with my shroud.

So I had to fire up my little CNC mill and cut some 7071 aluminum.

Next, I chucked up the new banjo fitting in my lathe to contour and bore it.

Cut the internal O-ring grooves.

Then drill it to fit the QF nipple.

After looking at the Raw unit…I decided I didn’t need a Reg.

So, I chucked up a spare Fast-flow into the old lathe and did some cutting.

So now I have a couple of options now……

Now comes the sweat palms…I need to drill my Custom Laminate DaveG Stock.

First I had to modify my QF Stock Drilling Jig.

I added a 2nd hole to match the new position of the QF nipple.

Now using the same 1 inch Forstner Bit, I drilled the hole through my stock.

Next I had to decide how I would dress up this hole.

Delrin just didn’t look right. So I decided on brass.

Also what to do about a cover…..

This is what I came up with!

I Threaded the brass liner and made a threaded cover to match.

I use the same QF socket with the Delrin extension I made for the Dr Bob’s QF to inflate my Rapid.

I hope you enjoyed this as much I did doing it!!

Atb,

Stuart

This is the second part of installing QF's on a Rapid MKII

For Part 1

Now on to the RAW QF kit. It replaces your Reg adapter. It comes with a new reg/bottle adapter and banjo fitting with gauge and QF nipple.

This one I had to make a custom banjo fitting.

Since the stock one with the Gauge would not fit with my shroud.

So I had to fire up my little CNC mill and cut some 7071 aluminum.

Next, I chucked up the new banjo fitting in my lathe to contour and bore it.

Cut the internal O-ring grooves.

Then drill it to fit the QF nipple.

After looking at the Raw unit…I decided I didn’t need a Reg.

So, I chucked up a spare Fast-flow into the old lathe and did some cutting.

So now I have a couple of options now……

Now comes the sweat palms…I need to drill my Custom Laminate DaveG Stock.

First I had to modify my QF Stock Drilling Jig.

I added a 2nd hole to match the new position of the QF nipple.

Now using the same 1 inch Forstner Bit, I drilled the hole through my stock.

Next I had to decide how I would dress up this hole.

Delrin just didn’t look right. So I decided on brass.

Also what to do about a cover…..

This is what I came up with!

I Threaded the brass liner and made a threaded cover to match.

I use the same QF socket with the Delrin extension I made for the Dr Bob’s QF to inflate my Rapid.

I hope you enjoyed this as much I did doing it!!

Atb,

Stuart