A Unique features about the Rapid MKII is how few O-rings are used in it's design.

One area is the Barrel to Bolt Probe. It uses a machined, and lapped surfaces to create a seal. No O-rings used..

So I like to adjust my bolt lockup to be on the tight side!

To ensure no air blow-by leaks...This make for a notchy lock-up.

Well even with grease and polishing of the bolt stem, it would need to be adjusted and machined for wear...

So I decided to try out a 3-piece Bolt Handle. It would incorporate

A rotating sleeve, to act ás a bearing.

So first I started with my Titanium bolt handle I made..

I cut the stem off my Titanium Bolt on my lathe.

Then tap the body for 10-32 threads

Next I cut a stub shaft out of S7 tool steel. Threaded it for 1/4-28 on one end and 10-32 on the other end.

Then I made rotating bearing sleeve out of S7 too.

Polished both the stub shaft, and the sleeve(inside and out), for a smooth fit and easy rotation.

I also applied a dab of krytox synthetic grease on the stub shaft before assembly for good measure..

___________________________

Next I focused on the Tactical Bolt handles.....

These are Tactical bolt handles used in Centerfire Bolt action rifles

So the Tactical Bolt knob has 5/16-24. So I had to fabricate a brass insert with 10-32 for the stem..

So the stem and bearing sleeve is made like my other one...Out of S7 tool steel.

Here is what it looks like....

I forgot I also had to mill a couple of flats on the brass insert to help cinching it up to the bolt handle.

Results so far is a superior smooth lockup, even having the probe tension adjusted on the tight side!!

Stuart

One area is the Barrel to Bolt Probe. It uses a machined, and lapped surfaces to create a seal. No O-rings used..

So I like to adjust my bolt lockup to be on the tight side!

To ensure no air blow-by leaks...This make for a notchy lock-up.

Well even with grease and polishing of the bolt stem, it would need to be adjusted and machined for wear...

So I decided to try out a 3-piece Bolt Handle. It would incorporate

A rotating sleeve, to act ás a bearing.

So first I started with my Titanium bolt handle I made..

I cut the stem off my Titanium Bolt on my lathe.

Then tap the body for 10-32 threads

Next I cut a stub shaft out of S7 tool steel. Threaded it for 1/4-28 on one end and 10-32 on the other end.

Then I made rotating bearing sleeve out of S7 too.

Polished both the stub shaft, and the sleeve(inside and out), for a smooth fit and easy rotation.

I also applied a dab of krytox synthetic grease on the stub shaft before assembly for good measure..

___________________________

Next I focused on the Tactical Bolt handles.....

These are Tactical bolt handles used in Centerfire Bolt action rifles

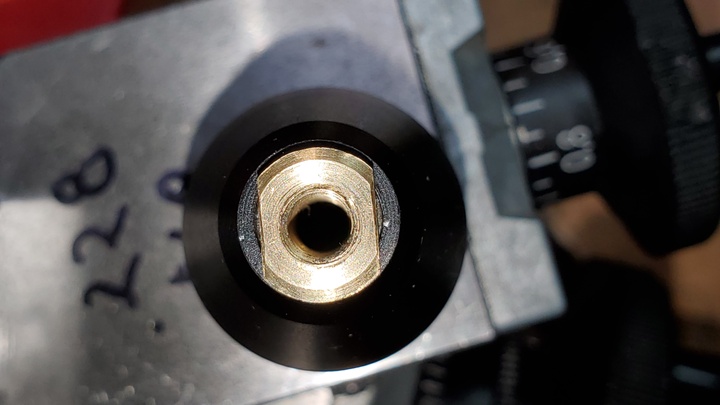

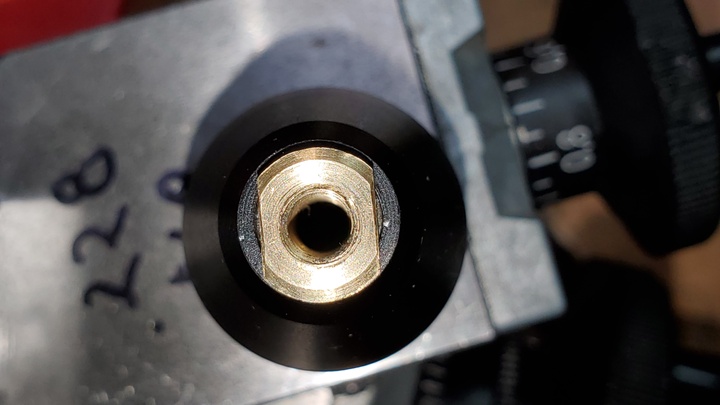

So the Tactical Bolt knob has 5/16-24. So I had to fabricate a brass insert with 10-32 for the stem..

So the stem and bearing sleeve is made like my other one...Out of S7 tool steel.

Here is what it looks like....

I forgot I also had to mill a couple of flats on the brass insert to help cinching it up to the bolt handle.

Results so far is a superior smooth lockup, even having the probe tension adjusted on the tight side!!

Stuart

Last edited: