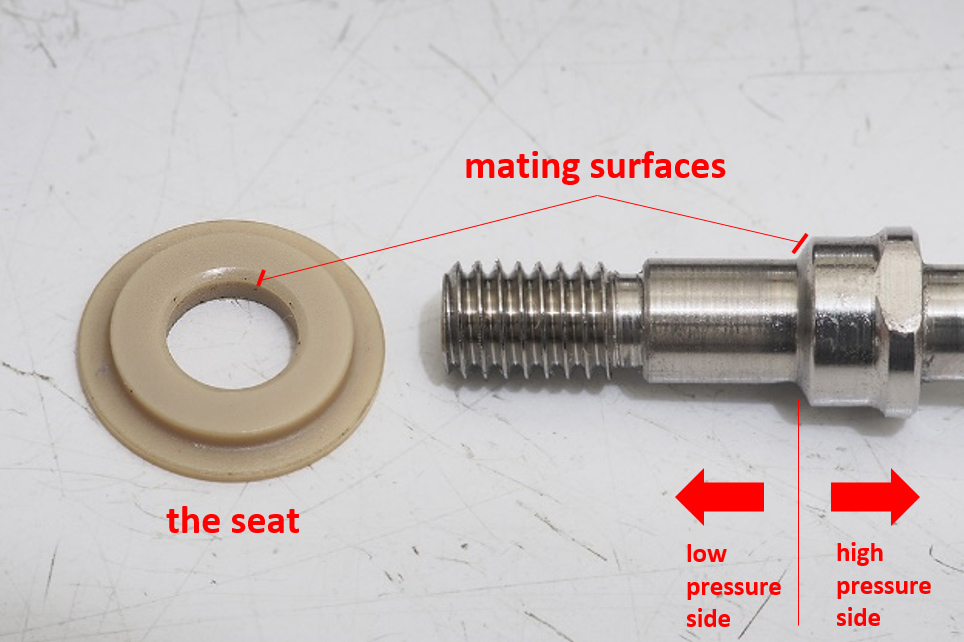

My Huben K1 ( version 2 ) has rather sever regulator creep and after reading many posts on this subject, I came to the understanding that it can be fixed by improving the mating between the seat and the piston ( if that is the correct term ) that do the sealing between the high and low pressure end of the regulator.

This is the structure of the seat and the piston inside the regulator of my Huben.

I understand it can be done by lapping but I don't quite know how to do it, e.g. do you apply some lapping compound like Brasso to the mating surface and rub the seat against the piston ? how do you hold the two parts to make sure that they are aligned ? Grateful if someone can share some experience.

This is the structure of the seat and the piston inside the regulator of my Huben.

I understand it can be done by lapping but I don't quite know how to do it, e.g. do you apply some lapping compound like Brasso to the mating surface and rub the seat against the piston ? how do you hold the two parts to make sure that they are aligned ? Grateful if someone can share some experience.