Ok, I’m done for the night.

This was a use what you have build. I did need to buy a dimmer switch, Less than $9.

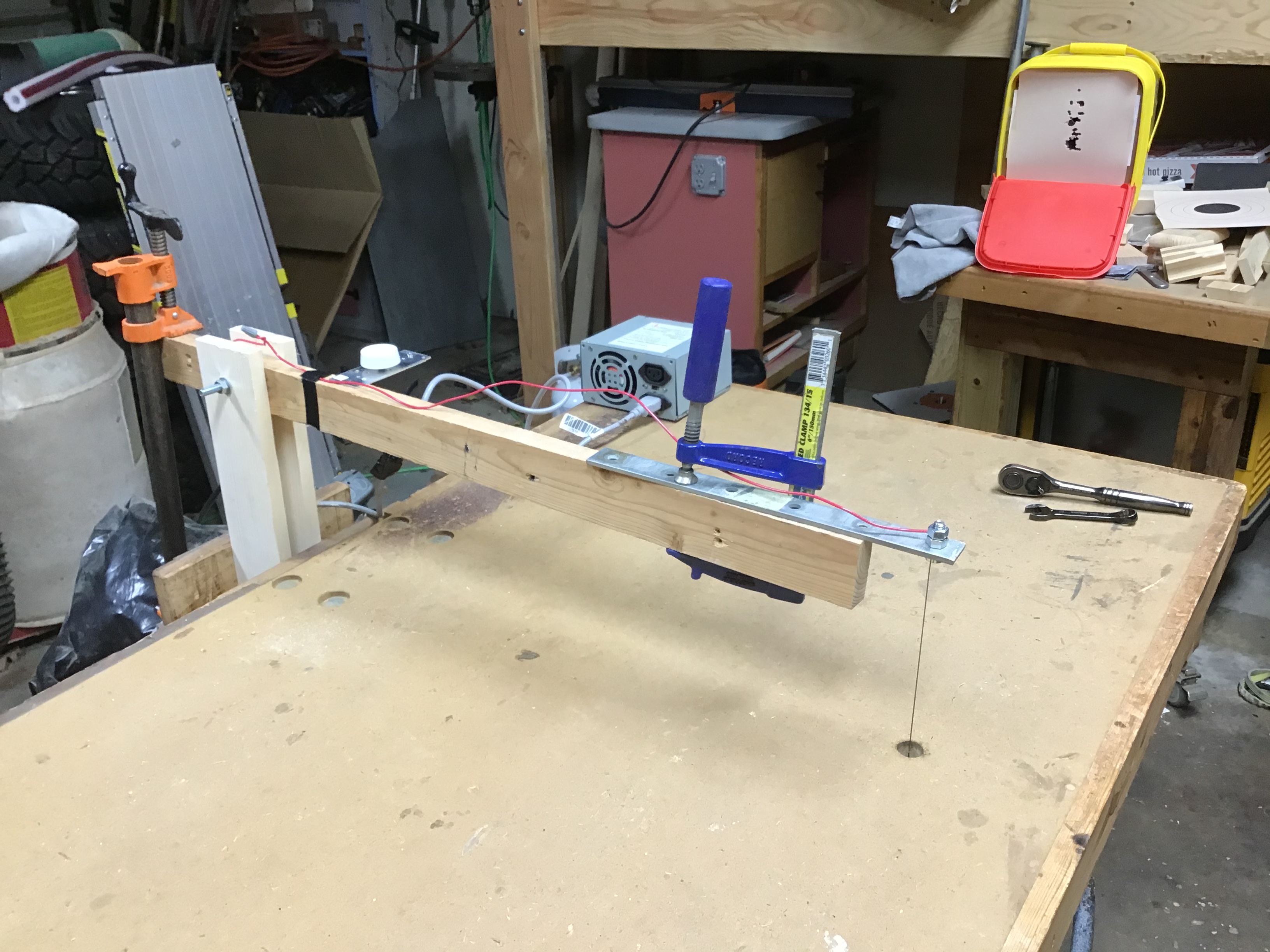

power supply is some sort of computer power supply. Pulled it from a dumpster on a job site years ago, probably a decade ago. Everything else is just garage stuff.

I got lucky with my “cutting wire”. A lot of the diy hot wire cutter tutorials say to use guitar string. My son is a professional guitar player. There is plenty of used strings around. I could not get one to last more than a few minutes. I tried a ton of them. Turns out I had this spool of unknown wire. Thought it was steel but turns out it’s not. No labels on the spool. It’s not magnetic. It works great for a hot cutter wire. Glad I tried it, got lucky.

The dimmer switch controls the voltage. Thought I’d be able to use it on the output side of the power supply. 12 volt dc. I couldn’t get it to work so I just wired the dimmer into the AC input side of the power supply. I’m sure its bad for the power supply but I don’t care. It does’t work too low but can get down to about 6.5 volts in the working circuit. 7.25 volts was about the best. Too hot and you burn your foam. Too little and it doesn’t cut well.

Wire was just glowing slightly while cutting.

I didn’t want to build a whole assembly. Who needs more stuff laying around. I was able to turn a woodworking table into a temporary hot wire cutter. Already had the hole in the table for a clamp, vice was there. Used a bar clamp as a tensioning device. I’ll keep it set up for a few days. Got some other cases to cut after I finish this.

I’m just rambling nonsense now...