Hi all,

I’m new here so be gentle with me! The Covid lockdown has re-kindled my interest in airguns after 10 years so I thought I might show something that you may not have seen before.

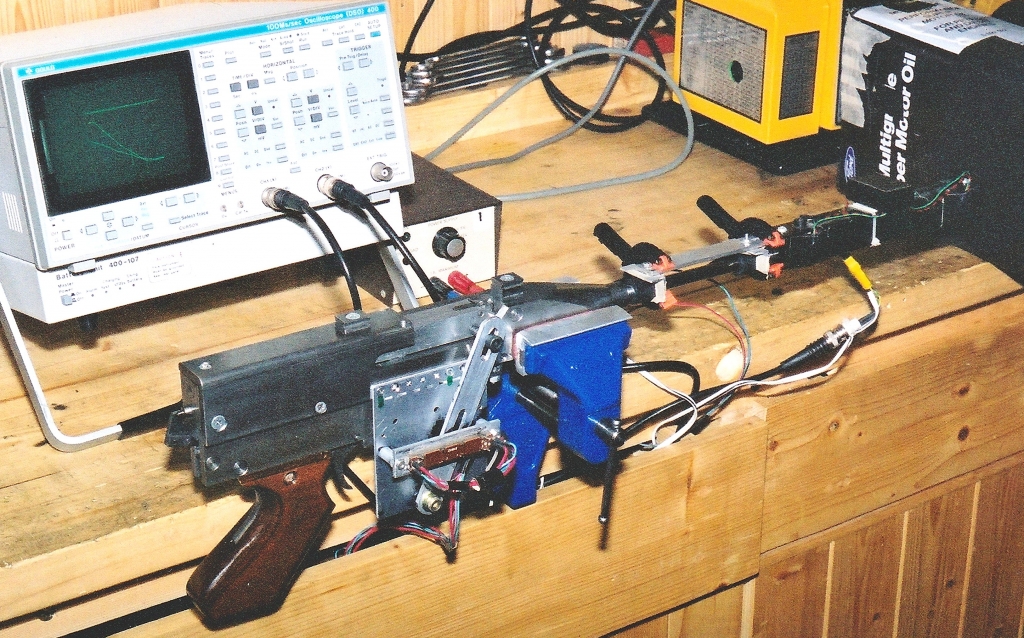

This is my homemade M16 semi-automatic air cartridge rifle, it shoots 0.177 pellets at about 9ft.lbs the magazine carries up to 15 self-contained precharged air cartridges. These cartridges were made by Brocock in the UK for use in a range of revolvers and rifles such as modified Weihrauch Arminius 38cal revolvers and the Urberti yellowboy rifle. I have one of the Arminius revolvers re-badged by Brocock as the Orion and a fine thing it is, accurate and delivering a full 6 ft. Lbs after using this for a few months and accumulating a large number of cartridges I decided what was needed was a semi-automatic rifle! There were some air cartridge auto cycling pistol conversions available at the time which operated by telescoping to double their original length to operate the action before releasing the air pressure to fire a plastic projectile but power levels and accuracy were poor largely due to the significant motion of the slide before the projectile was fired . I decided therefore to design a system which would store and augment the waste air pressure and apply it to the bolt after the pellet left the bore. What was needed was a test rig to measure pellet speed, bolt force and movement initially it was configured as a rifle but in the picture below is fitted with a six inch pistol barrel.

Using this showed that a cartridge exerted a recoil force of 1571 N or over 350 lbs force but only for 3.4 thousandths of a second. In my work at the time I was using some high powered CFD software to design tuned engine intake systems so I was able to model wave interactions with varying accumulator volume to magnify, delay and sustain the recoil pressure. This gave a starting point for the design but it took many hardware iterations before it was working reliably. At this stage I approached Brocock who asked me to design a rifle for them using this system, unfortunately at this time there were a few instances of criminals re-converting the Brocock pistols to fire live rounds, so in an ill-considered kneejerk reaction the British government banned all weapons using self-contained air cartridges which meant the project had to be cancelled. I was able to keep two of the prototypes along with the Orion pistol which are now classified as section 5 firearms (along with things such as sub-machine guns and assault rifles!) but I am not able to sell or otherwise dispose of them and they will have to be destroyed after my death. I do however still have the rights to the design and also that of the 1911 colt lookalike semi-automatic pistol that I was working on at the time of the ban. There are some links below to youtube videos of the rifle in action and also to the modified air pump I made to charge the cartridges.

Shooting: https://youtu.be/GTQIx_hKT54

Chrono testing: https://youtu.be/YKdfW5mdXFA

Cartridge pump: https://youtu.be/sxLz57loFFo

I’m new here so be gentle with me! The Covid lockdown has re-kindled my interest in airguns after 10 years so I thought I might show something that you may not have seen before.

This is my homemade M16 semi-automatic air cartridge rifle, it shoots 0.177 pellets at about 9ft.lbs the magazine carries up to 15 self-contained precharged air cartridges. These cartridges were made by Brocock in the UK for use in a range of revolvers and rifles such as modified Weihrauch Arminius 38cal revolvers and the Urberti yellowboy rifle. I have one of the Arminius revolvers re-badged by Brocock as the Orion and a fine thing it is, accurate and delivering a full 6 ft. Lbs after using this for a few months and accumulating a large number of cartridges I decided what was needed was a semi-automatic rifle! There were some air cartridge auto cycling pistol conversions available at the time which operated by telescoping to double their original length to operate the action before releasing the air pressure to fire a plastic projectile but power levels and accuracy were poor largely due to the significant motion of the slide before the projectile was fired . I decided therefore to design a system which would store and augment the waste air pressure and apply it to the bolt after the pellet left the bore. What was needed was a test rig to measure pellet speed, bolt force and movement initially it was configured as a rifle but in the picture below is fitted with a six inch pistol barrel.

Using this showed that a cartridge exerted a recoil force of 1571 N or over 350 lbs force but only for 3.4 thousandths of a second. In my work at the time I was using some high powered CFD software to design tuned engine intake systems so I was able to model wave interactions with varying accumulator volume to magnify, delay and sustain the recoil pressure. This gave a starting point for the design but it took many hardware iterations before it was working reliably. At this stage I approached Brocock who asked me to design a rifle for them using this system, unfortunately at this time there were a few instances of criminals re-converting the Brocock pistols to fire live rounds, so in an ill-considered kneejerk reaction the British government banned all weapons using self-contained air cartridges which meant the project had to be cancelled. I was able to keep two of the prototypes along with the Orion pistol which are now classified as section 5 firearms (along with things such as sub-machine guns and assault rifles!) but I am not able to sell or otherwise dispose of them and they will have to be destroyed after my death. I do however still have the rights to the design and also that of the 1911 colt lookalike semi-automatic pistol that I was working on at the time of the ban. There are some links below to youtube videos of the rifle in action and also to the modified air pump I made to charge the cartridges.

Shooting: https://youtu.be/GTQIx_hKT54

Chrono testing: https://youtu.be/YKdfW5mdXFA

Cartridge pump: https://youtu.be/sxLz57loFFo