Bringing back LLeons tread from the past, as I recently had a failure in both the cooling and compressor switches.

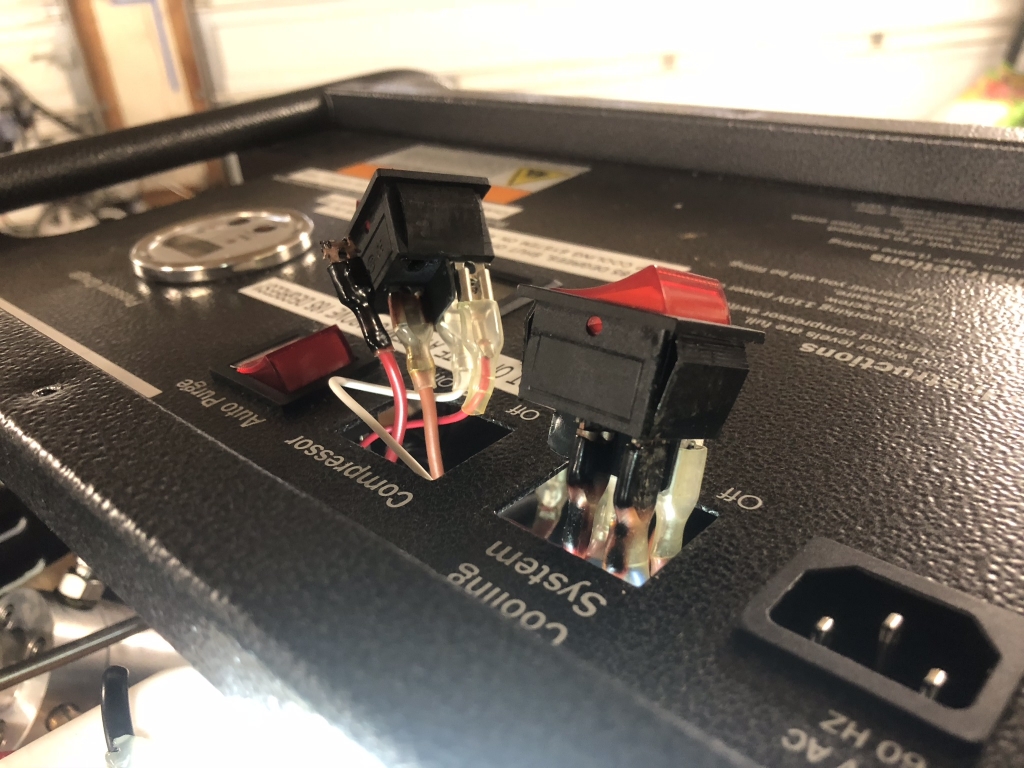

Compressor worked well two days before, but just as LLeon had said, it was making an unusual noise. Sounded more like I possibly had an air leak, which I knew I didn’t. Anyway, went to use it two days later to top off a tank and the voice comes on to say good to go, but no power to the compressor. Looked at the compressor switch and one leg was fried, and the spade terminal just snapped off of the switch upon light handling. The coolant switch wasn’t that bad, but the leg that ties in from the compressor switch to the coolant switch terminal was slightly fried.

Called Hatsan at 1:30pm CA time and Sean answered. After letting him know what happened, two new switches were on the way. To all the ones out there that have any doubt in Hatsan’s customer service, let this be proof that they are A1 in that department. To date, they have never let me down on any issues I have had with two of my Hatsan purchases, the Lightning compressor and my Hercules Bully. Thank you, Hatsan Sean!

Got both switches in place, but this time I soldered the terminals to the new wiring I used. I also increased the wire size one size up, and also soldered the push on terminal to the switch legs. I truly feel the vibrations from the compressor loosen these terminals and cause sparks which end up in fried parts. Common sense tells me solder will prevent this. I also used one wire at each leg, vs piggy backing two or three onto one spade like it came from the factory, and used wire nuts down hill to re connect bundled connections. Didn’t use just electrical tape on the connections, either, but instead anti vibration tape.

I turned on the compressor, and man, it sure sounds way different. Sounds like it’s brand new, no clacking, hissing, nothing. Makes me think when wires aren’t making solid contact with electrical connections, it would sound like bad timing in a vehicle, causing weird noises.

I also found a source on Amazon for these exact same switches. They are inexpensive, so I’m going to pick up a couple more just to have as back up.

To any AV and Lightning owners, my advice to you all is to make it a maintenance step to pop off the metal housing covers and check on your switch terminals for any signs of burn marks on them, so you can catch it before anything catastrophic happens. I consider myself lucky that only the switches fried.

https://www.amazon.com/URBEST-KCD4-Rocker-Switch-Motorcycle/dp/B01M0S57NA

Compressor worked well two days before, but just as LLeon had said, it was making an unusual noise. Sounded more like I possibly had an air leak, which I knew I didn’t. Anyway, went to use it two days later to top off a tank and the voice comes on to say good to go, but no power to the compressor. Looked at the compressor switch and one leg was fried, and the spade terminal just snapped off of the switch upon light handling. The coolant switch wasn’t that bad, but the leg that ties in from the compressor switch to the coolant switch terminal was slightly fried.

Called Hatsan at 1:30pm CA time and Sean answered. After letting him know what happened, two new switches were on the way. To all the ones out there that have any doubt in Hatsan’s customer service, let this be proof that they are A1 in that department. To date, they have never let me down on any issues I have had with two of my Hatsan purchases, the Lightning compressor and my Hercules Bully. Thank you, Hatsan Sean!

Got both switches in place, but this time I soldered the terminals to the new wiring I used. I also increased the wire size one size up, and also soldered the push on terminal to the switch legs. I truly feel the vibrations from the compressor loosen these terminals and cause sparks which end up in fried parts. Common sense tells me solder will prevent this. I also used one wire at each leg, vs piggy backing two or three onto one spade like it came from the factory, and used wire nuts down hill to re connect bundled connections. Didn’t use just electrical tape on the connections, either, but instead anti vibration tape.

I turned on the compressor, and man, it sure sounds way different. Sounds like it’s brand new, no clacking, hissing, nothing. Makes me think when wires aren’t making solid contact with electrical connections, it would sound like bad timing in a vehicle, causing weird noises.

I also found a source on Amazon for these exact same switches. They are inexpensive, so I’m going to pick up a couple more just to have as back up.

To any AV and Lightning owners, my advice to you all is to make it a maintenance step to pop off the metal housing covers and check on your switch terminals for any signs of burn marks on them, so you can catch it before anything catastrophic happens. I consider myself lucky that only the switches fried.

https://www.amazon.com/URBEST-KCD4-Rocker-Switch-Motorcycle/dp/B01M0S57NA

Upvote 0