I've been meaning to create a "How To" adjust the Hammer Spring Tension (HST) screw on a Hatsan Bully, but have been having fun on the range at IndainaAirguns.com

Anyway, I thought I better do it now or I won't get a chance for a while.

Cliff Note: You have to separate the stock from the action (gun) to access the locking grub screw for the HST screw and the HST screw.

Step 1

Safety first.

Always keep the muzzle of the airgun pointed in a safe direction. Unload the magazine from the Bully. Ensure there is not a pellet chambered. Ensure the Bully is uncocked. Put the safety on.

I actually shot mine down to empty. There's no pressure in the gun. I did this so I can tear it apart and see if I can get a regulator in it. You don't have to empty the air from the cylinder.

Step 2

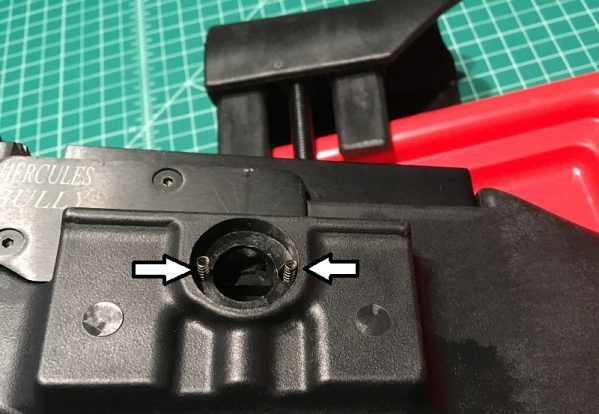

I recommend you tilt the Hatsan Bully on its side as shown in photo below. If you don't, you'll be hunting for springs in just a minute ... not that this would happen to me

Press the cheek weld adjustment button in and simultaneously pull the cheek weld completely out.

Step 3

Remove the Cheek Weld adjustment button carefully. There are 2 springs underneath it (see arrows in photo below). Remove and store the springs in a safe place.

Step 4

Turn the rifle upside down. Locate the first of two stock screws. The first is next to the manometer. It's a 4.5mm hex screw. See photo below. Remove this screw.

Step 5

Locate the second stock screw right behind the magazine storage compartment. It's a 4.5mm hex screw. See photo below. Remove this screw.

Step 6

Take your time, and slowly rock the stock loose from the action. (see below). The first couple of times, it's tight. I've done it so many time now, I have no problems getting it on and off.

Step 7

The Hammer Spring Tension (HST) screw is locked into place by a 2.5mm hex grub screw on the side of the gun (see arrow in photo below). This grub screw has to be backed almost all the way out in order to allow the HST screw to be adjusted. If you're trying to to adjust the HST screw and it won't turn ... this is most likely why.

Step 8

Looking at the back of the gun, there are 3 holes. The HST screw is the bottom hole (see photo below).

Clockwise will increase hammer spring tension pre-load, which will increase your velocity / FPS

Counter clockwise will decrease hammer spring tension pre-load, which will decrease your velocity / FPS

I believe this is opposite of older Hatsan airgun models.

Step 9

I use a caliper to measure the depth from the back of the gun to the top of the hammer spring tension screw. I've been careful not to fall into the slot of the screw. Record your depth with your shot string results for future reference.

Step 10

Re-assemble in reverse order.

-Rich

Anyway, I thought I better do it now or I won't get a chance for a while.

Cliff Note: You have to separate the stock from the action (gun) to access the locking grub screw for the HST screw and the HST screw.

Step 1

Safety first.

Always keep the muzzle of the airgun pointed in a safe direction. Unload the magazine from the Bully. Ensure there is not a pellet chambered. Ensure the Bully is uncocked. Put the safety on.

I actually shot mine down to empty. There's no pressure in the gun. I did this so I can tear it apart and see if I can get a regulator in it. You don't have to empty the air from the cylinder.

Step 2

I recommend you tilt the Hatsan Bully on its side as shown in photo below. If you don't, you'll be hunting for springs in just a minute ... not that this would happen to me

Press the cheek weld adjustment button in and simultaneously pull the cheek weld completely out.

Step 3

Remove the Cheek Weld adjustment button carefully. There are 2 springs underneath it (see arrows in photo below). Remove and store the springs in a safe place.

Step 4

Turn the rifle upside down. Locate the first of two stock screws. The first is next to the manometer. It's a 4.5mm hex screw. See photo below. Remove this screw.

Step 5

Locate the second stock screw right behind the magazine storage compartment. It's a 4.5mm hex screw. See photo below. Remove this screw.

Step 6

Take your time, and slowly rock the stock loose from the action. (see below). The first couple of times, it's tight. I've done it so many time now, I have no problems getting it on and off.

Step 7

The Hammer Spring Tension (HST) screw is locked into place by a 2.5mm hex grub screw on the side of the gun (see arrow in photo below). This grub screw has to be backed almost all the way out in order to allow the HST screw to be adjusted. If you're trying to to adjust the HST screw and it won't turn ... this is most likely why.

Step 8

Looking at the back of the gun, there are 3 holes. The HST screw is the bottom hole (see photo below).

Clockwise will increase hammer spring tension pre-load, which will increase your velocity / FPS

Counter clockwise will decrease hammer spring tension pre-load, which will decrease your velocity / FPS

I believe this is opposite of older Hatsan airgun models.

Step 9

I use a caliper to measure the depth from the back of the gun to the top of the hammer spring tension screw. I've been careful not to fall into the slot of the screw. Record your depth with your shot string results for future reference.

Step 10

Re-assemble in reverse order.

-Rich