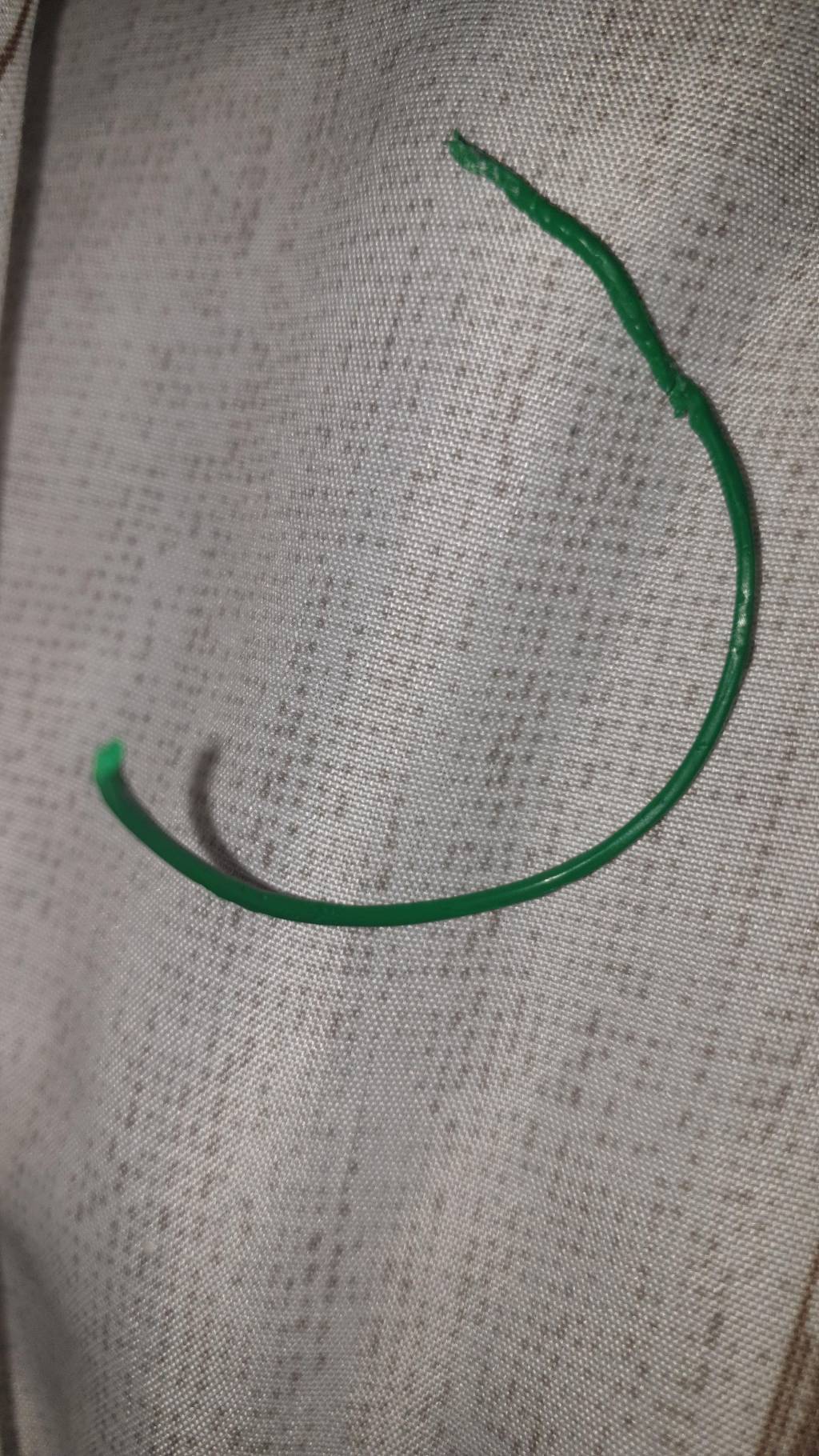

Anyone who owns one of the big tuxing gold filter knows they come with the green o rings instead of black. Sometimes when filling up your tanks, the green o ring would get squeeze out from the gap. Even when it doesnt, you open the cap and the o ring is like flaking off or shedding its skins like a snake. It would get crusty and break up and not rubbery like the black o ring.

Is there a difference between the green o rings vs black o rings. Is there a reason why tuxing is using the green o rings? I am thinking of ordering some black one same size to replace. Would that be a good idea or not? Why would they use these type of green o rings when it see so bad.

Is there a difference between the green o rings vs black o rings. Is there a reason why tuxing is using the green o rings? I am thinking of ordering some black one same size to replace. Would that be a good idea or not? Why would they use these type of green o rings when it see so bad.