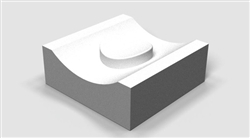

This was a brand spank'n new P-rod, never been fired, my neighbor gave it to me. It was made in 2018 so I decided to order everything new from Tim Hill and rebuild it (105 kit, hammer, springs, PEEK striker, depinger, moderator, gauge block, and gauge). I rebuilt it, shot hundreds of rounds through it over the last 2 weeks, developed a leak, took it apart and when I did this happened. I met resistance when pushing it out, not sure what happened.

My question is can I just buff out the gouges with Cratex (fine carbide in a rubber matrix), re-gasket and re-install?

My question is can I just buff out the gouges with Cratex (fine carbide in a rubber matrix), re-gasket and re-install?