I've seen photos on here, and on Ernest Rowes YouTube channel. Looking for any info on sourcing parts and making one of these, and how effective they are. I have the new Superior 700mm ordered from Utah, and would consider doing the mod if it is an improvement. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FX STX carbon fiber liner sleeve.

- Thread starter DShepard

- Start date

Saw it and really want to try it too but after some research the in diameter needs to be 9.25mm and must be pressed on to ensure snug fit and outer is around 12.8mm For my .25. From the look of it a press and lathe would be minimum to do the job right. Another approach would be carbon fabric wrap but you need to add your own epoxy and need to figure out how to ensure OD is consistent and sadly a lathe is pretty much required anyways.

this however does present itself as a great little business opportunity if someone has a good lathe. I’m a big fan of carbon barrels!

this however does present itself as a great little business opportunity if someone has a good lathe. I’m a big fan of carbon barrels!

Upvote 0

I really was expecting that carbon sleeve ,where easy to install, not to need a lathe for it need to sleeve 3 barrels ... could some one that have done it throw us light about it...

Upvote 0

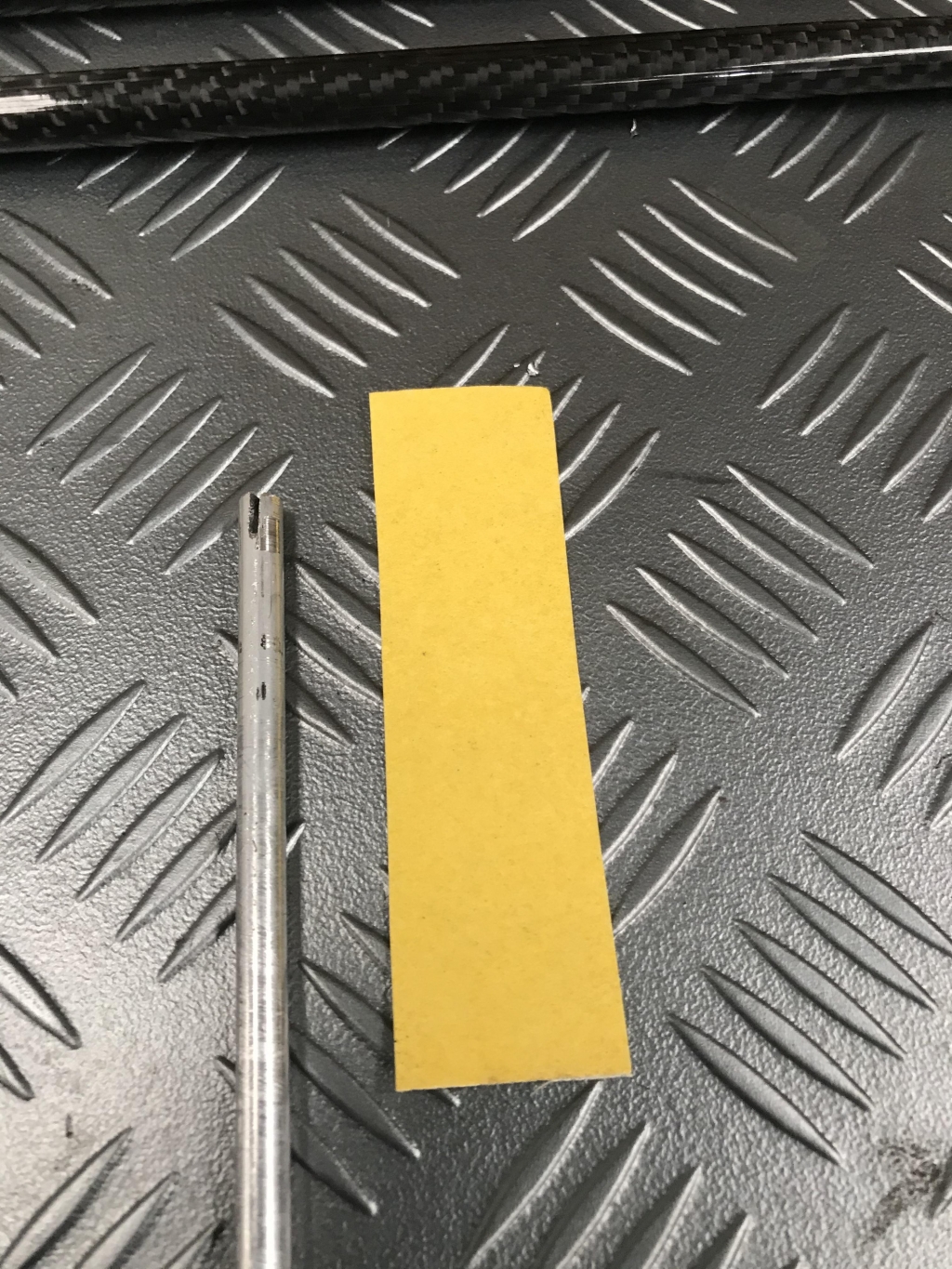

I did mine in 22 cal. With a 8mmX10mm carbon fiber tube. Can't say if it helped for sure. Was a laser to begin with. But definitely stiffens the barrel. Here's a pic of my set up. Left a gap in the middle for 2 orings to support the center of the 700mm barrel. For sure a lot less oring fiddling around this way.

Upvote 0

You don’t need a lathe to do this properly. In fact you can do a better job without a lathe This is because the outside diameter of the liner isn’t actually even over it’s length. The best way to do it is get a 6mm aluminium rod about 600mm long. Put a slot in the end to slide your sandpaper into and you now have your hone to put in your drill. Cut yourself a few lengths of sandpaper that when wound on fit snugly in the CF sleeve. Once you find the right length cut plenty as they don’t last long.

When you try to slide the CF tube on you will see one end is tighter than the other so slide it on the narrow end. It takes some time and patience but just keep honing and trying it again and again. You will find that twisting tThe tube will help to get it on as the rifling acts as a thread.

once you get it on in the position you need clean out the inside of the CF tube well. Use your sandpaper and ruff up (Key)your liner to get a better bond.

Put a thin coat of Araldite on the liner and slide/twist your CF sleeve into position. Wipe off excess Araldite. Check your position of the tube carefully!

This isn’t a difficult task. Measure carefully and take your time.

http://www.carbonfiber.com.au/prod84.htm

These are the tubes I use. If you want it super stiff you can put a 10mm by 12mm over the top of the 8mm /10mm for .22 cal. This just slides snuggly into the out barrel.

This one has the 8/10 and 10/12 Stiffer than a steel barrel!

When you try to slide the CF tube on you will see one end is tighter than the other so slide it on the narrow end. It takes some time and patience but just keep honing and trying it again and again. You will find that twisting tThe tube will help to get it on as the rifling acts as a thread.

once you get it on in the position you need clean out the inside of the CF tube well. Use your sandpaper and ruff up (Key)your liner to get a better bond.

Put a thin coat of Araldite on the liner and slide/twist your CF sleeve into position. Wipe off excess Araldite. Check your position of the tube carefully!

This isn’t a difficult task. Measure carefully and take your time.

http://www.carbonfiber.com.au/prod84.htm

These are the tubes I use. If you want it super stiff you can put a 10mm by 12mm over the top of the 8mm /10mm for .22 cal. This just slides snuggly into the out barrel.

This one has the 8/10 and 10/12 Stiffer than a steel barrel!

Upvote 0

I diddent glue mine, if fittet so nice that i thought i would try without, so i put some o-ring on to the corbon tube so it fits in the barrel and i can just take out the liner when changing it, super easy and super stiff.

Upvote 0

I'm just copying / pasting my original comments from Ernest's original video:

"DirtyDovihttps://www.youtube.com/watch?v=MLbWg0TfBCw&lc=UgzuZW7G-YyibXYBFfN4AaABAg.982xR8PqrwQ984rkvmitj3

While there are many different sources for carbon fiber tubing, I've always just used sellers on eBay. Quality has been top notch so no complaints from me. I've used cf for one off customer builds when I had my custom shops, and I've used cf sheet and tubing for building tricopter and quadcopter arms and frames. Same for custom air rifle components. For this sort of thing, a good example is this option: 3K Carbon Fiber Tubing - "1pcs 10mm x 8mm x 1000mm Matte Plain" https://www.ebay.com/itm/3K-Carbon-Fiber-Tube-1000mm-Length-OD5mm-6mm-7mm-8mm-9mm-10mm-Rod-Pipe-Shaft-1M/133354766394?hash=item1f0c90403a:m:m3N_HzeMi34ErUUGfgAMUlQ Total w/ shipping under $20 bucks, stock in CA / US, and fast shipping.

Sam -"

Sam -"

And...

"DirtyDovihttps://www.youtube.com/watch?v=MLbWg0TfBCw&lc=UgzuZW7G-YyibXYBFfN4AaABAg.982xR8PqrwQ987RnG_OolF

@John Babb To sand the inside of a tube, you just warp sandpaper or emery-paper around a mandrel [wooden / metal dowel] The mandrel should be close to the same size id of the tube you'd be sanding, and then when wrapped, the paper would take up the rest of the size.. You can work the sanding actual back and forth manually, or, chuck the mandrel into a drill or lathe to get it spinning, and then move the tube around it as needed."

Sam -

"DirtyDovihttps://www.youtube.com/watch?v=MLbWg0TfBCw&lc=UgzuZW7G-YyibXYBFfN4AaABAg.982xR8PqrwQ984rkvmitj3

While there are many different sources for carbon fiber tubing, I've always just used sellers on eBay. Quality has been top notch so no complaints from me. I've used cf for one off customer builds when I had my custom shops, and I've used cf sheet and tubing for building tricopter and quadcopter arms and frames. Same for custom air rifle components. For this sort of thing, a good example is this option: 3K Carbon Fiber Tubing - "1pcs 10mm x 8mm x 1000mm Matte Plain" https://www.ebay.com/itm/3K-Carbon-Fiber-Tube-1000mm-Length-OD5mm-6mm-7mm-8mm-9mm-10mm-Rod-Pipe-Shaft-1M/133354766394?hash=item1f0c90403a:m:m3N_HzeMi34ErUUGfgAMUlQ Total w/ shipping under $20 bucks, stock in CA / US, and fast shipping.

And...

"DirtyDovihttps://www.youtube.com/watch?v=MLbWg0TfBCw&lc=UgzuZW7G-YyibXYBFfN4AaABAg.982xR8PqrwQ987RnG_OolF

@John Babb To sand the inside of a tube, you just warp sandpaper or emery-paper around a mandrel [wooden / metal dowel] The mandrel should be close to the same size id of the tube you'd be sanding, and then when wrapped, the paper would take up the rest of the size.. You can work the sanding actual back and forth manually, or, chuck the mandrel into a drill or lathe to get it spinning, and then move the tube around it as needed."

Sam -

Upvote 0

Hi guys!!!!

I do not have any STX liner but watching Ernest's video it would not be easier to mechanize the liner and install the transfer port and moderator thread on the liner and cover it with carbon fiber canceling the original lining. It's a question I have never had an STX liner in my hands

Regards

Enkey

I do not have any STX liner but watching Ernest's video it would not be easier to mechanize the liner and install the transfer port and moderator thread on the liner and cover it with carbon fiber canceling the original lining. It's a question I have never had an STX liner in my hands

Regards

Enkey

Upvote 0

The grub screw that fixes the barrel in place must go against steel. The CF will fracture at that point. Also with the Impact the cocking block slides up and down on the barrel. The CF won’t cope with that.

you could have CF everywhere else. You might want a metal tread for your silencer also.

you could have CF everywhere else. You might want a metal tread for your silencer also.

Upvote 0

I would not do it. Usually, the CF sleeve is epoxied on the to barrel or liner in this case. While it looks cool, it could cause other problems. The coefficient of thermal expansion for the steel vs carbon is different. As temperature changes, the barrel will grow more than the CF, causing big changes in POI. Just a point to ponder.

Upvote 0

I would not do it. Usually, the CF sleeve is epoxied on the to barrel or liner in this case. While it looks cool, it could cause other problems. The coefficient of thermal expansion for the steel vs carbon is different. As temperature changes, the barrel will grow more than the CF, causing big changes in POI. Just a point to ponder.

That shouldn't be an issue if the CF tube is evenly distributed around the liner...just like the o-rings. It can be an issue when people make barrel braces out of plastic material that attach to the air tube.

Upvote 0

I Got to test mine today, and it had problem shooting sub moa at 100y don’t know if it is better then before but it a hell of a lot easyer to change liners now ( not glued) and it is defferently much stiffer

Upvote 0

No. just going by the dimensions that were stated above where they said you could stack 10x12 over the 8x10 and still fit it inside the housing.

Upvote 0

Just a thought, instead of sand paper and dowel/rod. How about bronze brush and cleaning rod to increase the ID...

Upvote 0

A friend has a carbon sleeved .260 first few shots on point, but things becomes more random. Takes ages for the barrel to cool down. Not sure this would be the case with an air rifle as there is no chemical explosion to heat the barrel, not comparable to pellet friction.

Do we have an update on accuracy from this mod?

Do we have an update on accuracy from this mod?

Upvote 0

A friend has a carbon sleeved .260 first few shots on point, but things becomes more random. Takes ages for the barrel to cool down. Not sure this would be the case with an air rifle as there is no chemical explosion to heat the barrel, not comparable to pellet friction.

Do we have an update on accuracy from this mod?

Still a laser. Haven't touched a turret in months.

Upvote 0

I would maybe do for a look if the liner would stay visible but I would not do because,

I have a concern about straightness / wall thickness consistency (I tried to picture it in a simple word but you native english speaking people may have an exact word for it).

My archery target arrows for competition ... I am talking high-end quality and highest priced CarbonExpress or Easton...from every boxed set/dozen I can measure a spine and straightness deviation and 2 or 3 are not reaching to my expectation. These arrows shall perform in my competition and my score shall beat the other guy beside me.

Now, those above mentioned carbon fiber tubes are made even to cheaper standards, how precise is the wrapping on mandrel's and also the questionable CF compound they were using, combined with an epoxy that will for sure push the walls unevenly away from the steel liner (or bend the liner as well slightly ???)....yes, this will make the liner stiffer. But the question remains:

Will the end result, the numbers on the score card, justify this exercise?

From other side I have to admit I have no many liners to swap maybe once in several months, so I cannot speak about a convenience.

I have a concern about straightness / wall thickness consistency (I tried to picture it in a simple word but you native english speaking people may have an exact word for it).

My archery target arrows for competition ... I am talking high-end quality and highest priced CarbonExpress or Easton...from every boxed set/dozen I can measure a spine and straightness deviation and 2 or 3 are not reaching to my expectation. These arrows shall perform in my competition and my score shall beat the other guy beside me.

Now, those above mentioned carbon fiber tubes are made even to cheaper standards, how precise is the wrapping on mandrel's and also the questionable CF compound they were using, combined with an epoxy that will for sure push the walls unevenly away from the steel liner (or bend the liner as well slightly ???)....yes, this will make the liner stiffer. But the question remains:

Will the end result, the numbers on the score card, justify this exercise?

From other side I have to admit I have no many liners to swap maybe once in several months, so I cannot speak about a convenience.

Upvote 0