I have a problem with the pump. It resists in both up and down strokes, does not pump. I have started disassembly, have rebuild kit on order, need advice.

The patient:

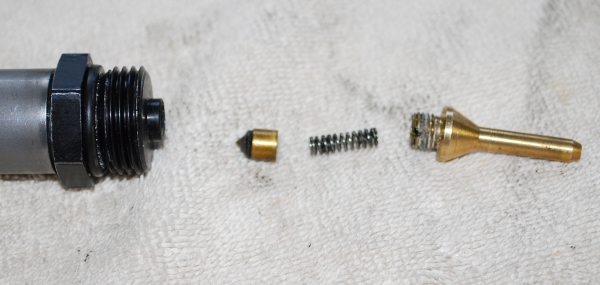

Brass "Large Piston" on the left is connected internally to black "main valve housing" right...

Large Piston with o-rings removed. Smaller o-rings appear to be shock absorbers.

Black "main valve housing." I used a piece of nylon tubing to protect the "valve pipe" while unscrewing. That work great.

I don't know how to proceed from this point. Advice please.

The patient:

Brass "Large Piston" on the left is connected internally to black "main valve housing" right...

Large Piston with o-rings removed. Smaller o-rings appear to be shock absorbers.

Black "main valve housing." I used a piece of nylon tubing to protect the "valve pipe" while unscrewing. That work great.

I don't know how to proceed from this point. Advice please.