Maverick started throwing some crazy errant low velocity shots the other day. Took the cheek piece off and looked at the probe position. The probe screw was right on the middle of the hole through the receiver not forward of center like it is supposed to be. Re adjusted and shot a bunch of perfect shots. The cocking rod must have slipped ever so slightly even though both of those garbage screws were tight. I swear I remember someone at some point mentioning changing them out? Can’t find the thread though. What size and type of screw? Does anyone know. It’s really silly they put those tiny things on this otherwise amazing gun.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FX FX Maverick cocking rod screw replacement??

- Thread starter Trucker3573

- Start date

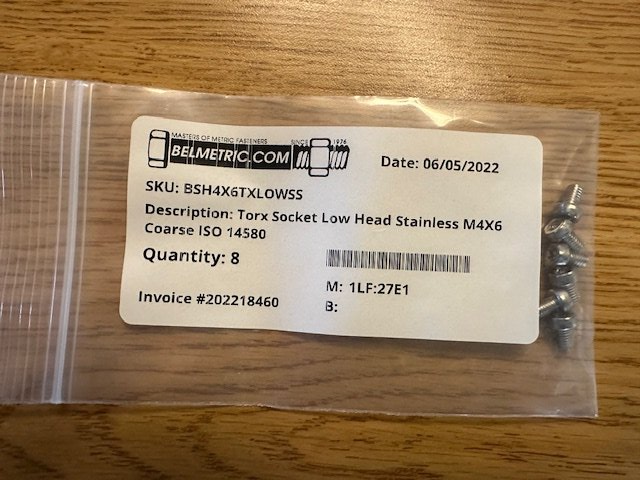

Check with Augie, but I got M4 x 6 Torx Socket Low Head Stainless per his recommendation.

Last edited:

Upvote 0

It doesn't take a lot of torque but it is a feel to get them just right and not have to order parts from FX/Utah AG. A dab of Purple or Blue, MUST BE REMOVABLE Loctite helps on the threads. Going with a bolt will give you too much torque, IMHO and you'll be either be ordering the part or drilling and tapping it to a larger size <--- also solves the issue,.

Upvote 0

I always wondered if making the area the screw touches on the rod flat, would help keep them in place

Upvote 0

Yes it would, extra bonus points if you make it so it can't move laterally and keep the proper length. But it need to be FLATI always wondered if making the area the screw touches on the rod flat, would help keep them in place

Upvote 0

This is what I did (post 69-70) https://www.airgunnation.com/threads/fx-maverick-full-beans.1176711/post-1423138Maverick started throwing some crazy errant low velocity shots the other day. Took the cheek piece off and looked at the probe position. The probe screw was right on the middle of the hole through the receiver not forward of center like it is supposed to be. Re adjusted and shot a bunch of perfect shots. The cocking rod must have slipped ever so slightly even though both of those garbage screws were tight. I swear I remember someone at some point mentioning changing them out? Can’t find the thread though. What size and type of screw? Does anyone know. It’s really silly they put those tiny things on this otherwise amazing gun.

Upvote 0

Thanks manThis is what I did (post 69-70) https://www.airgunnation.com/threads/fx-maverick-full-beans.1176711/post-1423138

Upvote 0

No problem. Just an FYI - if you haven't already realized the factory cocking rod stinks. It will surely come out bent up when you remove it. I replaced mine with some off the shelf 5/32 music wire, but it was a nightmare to thread with the M4 x0.7(?). I got rid of my lathe over a year ago, but if you can find someone to make one for you then I would HIGHLY recommend it. It takes a great deal of the slop out of the cocking action and mine hasn't bent after ~2 years of abuse.Thanks man

Upvote 0

Nice…yeah it is the one part of the gun that is crap. I sent mine back to FX early summer for the same problem but didn’t realize then how simple of a fix it actually is. They put a new rod in it then saying the Orig was bent. This one doesn’t seem bent. At least I know right away if it slips out of adjustment. When it’s out a little you can hear from the low power shots when they happen that the air flow is restricted.No problem. Just an FYI - if you haven't already realized the factory cocking rod stinks. It will surely come out bent up when you remove it. I replaced mine with some off the shelf 5/32 music wire, but it was a nightmare to thread with the M4 x0.7(?). I got rid of my lathe over a year ago, but if you can find someone to make one for you then I would HIGHLY recommend it. It takes a great deal of the slop out of the cocking action and mine hasn't bent after ~2 years of abuse.

Upvote 0

You must have gotten some of the ones that FX inspected, I got some that missed inspection are all are nice and straight.No problem. Just an FYI - if you haven't already realized the factory cocking rod stinks. It will surely come out bent up when you remove it. I replaced mine with some off the shelf 5/32 music wire, but it was a nightmare to thread with the M4 x0.7(?). I got rid of my lathe over a year ago, but if you can find someone to make one for you then I would HIGHLY recommend it. It takes a great deal of the slop out of the cocking action and mine hasn't bent after ~2 years of abuse.

Upvote 0

Nope, it was straight when I bought the rifle new from UA. They should have used a stronger grade of steel or slightly larger rod diameter. A side effect of it bending is that can break the cocking rod guide, because the guide is a hollow 6xxx grade AL with an M8x1 thread going into the front support, and the wall is too damned thin under the thread to withstand lateral forces exerted from a bent cocking rod.You must have gotten some of the ones that FX inspected, I got some that missed inspection are all are nice and straight.

I was pretty furious when I broke my rod guide and decided that I liked my Maverick enough to dedicate the time to overhaul all of the weaksauce components. I fabricated a stronger guide from stainless tool steel and replaced the rod with music wire (C59-60 hardness) . Eventually found the time to do a more comprehensive overhaul with titanium and made another guide, cocking lever / handle, several probes, shroud / barrel tension locking ring, and the K&L stock rods. Also added 18-8 Helicoils for my scope rail and a bunch of other little poop that FX should have done from the get-go.

Last thing that I did was adding this M4 to keep the rod tensioned down properly in the lever adapter, but I might go ahead and beef up the two factory M3's to something larger. If I were FX, I would have threaded the adapter so a threaded cocking rod at the rear could serve as a micro adjustment mechanism for the probe to tune the projectile seating in the chamber throat for slugs. That tolerance can make a tremendous difference in group sizes.

Upvote 0

I've got two Mavericks, never have bent a rod, properly adjusted the block stops about .04 short of the back. You may want to put a brass/steel bushing in the pivot of the cocking handle, I had one on my used gun that was horribly elongated, but the owner was brutal on the gun, broke lots of things.Nope, it was straight when I bought the rifle new from UA. They should have used a stronger grade of steel or slightly larger rod diameter. A side effect of it bending is that can break the cocking rod guide, because the guide is a hollow 6xxx grade AL with an M8x1 thread going into the front support, and the wall is too damned thin under the thread to withstand lateral forces exerted from a bent cocking rod.

I was pretty furious when I broke my rod guide and decided that I liked my Maverick enough to dedicate the time to overhaul all of the weaksauce components. I fabricated a stronger guide from stainless tool steel and replaced the rod with music wire (C59-60 hardness) . Eventually found the time to do a more comprehensive overhaul with titanium and made another guide, cocking lever / handle, several probes, shroud / barrel tension locking ring, and the K&L stock rods. Also added 18-8 Helicoils for my scope rail and a bunch of other little poop that FX should have done from the get-go.

Last thing that I did was adding this M4 to keep the rod tensioned down properly in the lever adapter, but I might go ahead and beef up the two factory M3's to something larger. If I were FX, I would have threaded the adapter so a threaded cocking rod at the rear could serve as a micro adjustment mechanism for the probe to tune the projectile seating in the chamber throat for slugs. That tolerance can make a tremendous difference in group sizes.

Upvote 0

I've seen dozens and dozens of bent rods. It was a known issue to FX/FX USA as well. Unless they changed the rod material / spec, and tightened up the tolerances on the connected parts then any of them can get bent over time as a matter of simple physics.I've got two Mavericks, never have bent a rod, properly adjusted the block stops about .04 short of the back. You may want to put a brass/steel bushing in the pivot of the cocking handle, I had one on my used gun that was horribly elongated, but the owner was brutal on the gun, broke lots of things.

As far as the idea using brass or steel bushings goes, I never would have done anything like that. I wanted the factory lever parts gone. My personal rifle's cocking lever was horrendously sloppy out of the box, and they did a real minimum bar type job with the design of the lever linkage pin that started to work it's way out on me right away so I fabricated a fail proof lever action and press fit polished pin from a specific grade of Toolox (that doesn't gaul to this Ti) that I had that seats in a counterbore in the lever. Luckily FX made the linkage from steel and not AL. It's the only part on the lever system worth keeping IMO, so I never bothered to make another one.

I machined / polished my lever to a +/- 0.0001" tolerance that eliminated lateral slop without causing wear to the action. There's ways to tighten up the factory lever, but I went about it the correct way by making one with the right tolerance. The other design goal that I had for it was to add a lever retention feature so the lever stays in the closed position, because that floppy factory lever really pissed me off. This video shows what I'm talking about:

The system has been working perfectly for close to 2 years and somewhere north of 10,000 shots (and 2 NRL22 seasons). Spent way more time on it than I should have, but I'll never have to make another one.

P.S. - I would take great care of the probe carrier part #20304. The one that shipped with my rifle is made from (O2?) tool steel, and the replacements are poorly machined 6xxx AL. The tolerances on this new part suck, the one I got from FX USA was ~0.28mm too large and the thread for the rod wasn't straight at all (off by 8-9 degrees).

Upvote 0