Has anyone purchased an aftermarket "match grade" trigger for M3 or Panthera? They are apparently available from Daniele Rizzotto (Facebook and Youtube) as well as mubhaur (AGN and Youtube). If so, please let us all know what you think. Also, is an FX match grade trigger available from any other source?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FX FX Match Grade Trigger?

- Thread starter MikeAllen

- Start date

Infact now I have done some modifications to the OEM trigger which have brought this trigger to match grade level.Has anyone purchased an aftermarket "match grade" trigger for M3 or Panthera? They are apparently available from Daniele Rizzotto (Facebook and Youtube) as well as mubhaur (AGN and Youtube). If so, please let us all know what you think. Also, is an FX match grade trigger available from any other source?

Previously I have also uploaded a few videos on improving FX Impact triggers.

In my initial videos a year or more ago, I installed a ball detent plunger with adjustable spring tension to adjust the 2nd stage break to the user's liking.

Then I made a new design of trigger. It was very good but everyone couldn't adjust it right. I uploaded the video and also shared it with Fredrik.

This design was good but it had one drawback. The safety couldn't work in this new design.

It was good for target shooters only.

Initially I provided a couple to two shooters but this trigger needed very fine adjustments in each gun to work properly and it became difficult for user's to make it work right.

Then I stopped providing this design. The videos of this design are also uploaded on my channel.

Recently I saw a video of Sub 12 Airgunners. In that video he modified Panthera trigger.

An additional thing that he did to OEM trigger as compared to my early modifications to OEM trigger of Impact is that he changed the angle of wheel sear. I was not in favour of changing any angles of sears previously as this may become dangerous. But when I inspected Impact trigger from this point of view, I found that Impact trigger sear angle can be changed without compromising safety.

Then I changed the angle of wheel sear gradually to the desired position.

All other mods were same which I had made a couple of years ago i.e. lightening the trigger return spring and also lightening the spring of ball detent plunger.

After micro adjustments and trying various tensions of trigger spring and ball detent spring alongwith changed angle of wheel sear, the result is amazing.

Now the trigger is light to the level of match grade triggers. The trigger comes back every time after pulling the 1st stage WITHOUT STICKING there at all.

The 2nd stage is also light, crisp and very predictable.

In result the Impact has become much easier to shoot accurately.

But triggers are such items which are difficult to export from my country.

I understand that if FX or any other after market parts manufacture makes triggers with above suggested modifications to OEM triggers, the trigger of Impact can become great.

Similarly if FX would pick my design of altogether new trigger with some improvements to install the pins at a bit different locations, the trigger can be great without any issues of engaging safety.

So the latest upgrade regarding which I uploaded the video yesterday is about changing the angle of wheel sear, using light trigger return spring and using lighter sprung ball detent plunger.

Please note that all modifications made to the triggers needs HIGH PRECISION to avoid any accident.

It's not recommended for common users who don't understand the cause and effect of the mechanism in depth.

Here is my latest video below regarding improving Impact trigger to match grade level.

Bhaur

Last edited:

Upvote 0

Thanks for your reply. I subscribe to your channel and I saw your new video this morning. Too bad you cannot export your trigger - I would love to try it! I undeyjow you used heat to make the spring ball detent lighter. Where did you obtain the lighter trigger return spring? Again thank you for your work and posts on YouTube.Infact now I have done some modifications to the OEM trigger which have brought this trigger to match grade level.

Previously I have also uploaded a few videos on improving FX Impact triggers.

In my initial videos a year or more ago, I installed a ball detent plunger with adjustable spring tension to adjust the 2nd stage break to the user's liking.

Then I made a new design of trigger. It was very good but everyone couldn't adjust it right. I uploaded the video and also shared it with Fredrik.

This design was good but it had one drawback. The safety couldn't work in this new design.

It was good for target shooters only.

Initially I provided a couple to two shooters but this trigger needed very fine adjustments in each gun to work properly and it became difficult for user's to make it work right.

Then I stopped providing this design. The videos of this design are also uploaded on my channel.

Recently I saw a video of Sub 12 Airgunners. In that video he modified Panthera trigger.

An additional thing that he did to OEM trigger as compared to my early modifications to OEM trigger of Impact is that he changed the angle of wheel sear. I was not in favour of changing any angles of sears previously as this may become dangerous. But when I inspected Impact trigger from this point of view, I found that Impact trigger sear angle can be changed without compromising safety.

Then I changed the angle of wheel sear gradually to the desired position.

All other mods were same which I had made a couple of years ago i.e. lightening the trigger return spring and also lightening the spring of ball detent plunger.

After micro adjustments and trying various tensions of trigger spring and ball detent spring alongwith changed angle of wheel sear, the result is amazing.

Now the trigger is light to the level of match grade triggers. The trigger comes back every time after pulling the 1st stage WITHOUT STICKING there at all.

The 2nd stage is also light, crisp and very predictable.

In result the Impact has become much easier to shoot accurately.

But triggers are such items which are difficult to export from my country.

I understand that if FX or any other after market parts manufacture makes triggers with above suggested modifications to OEM triggers, the trigger of Impact can become great.

Similarly if FX would pick my design of altogether new trigger with some improvements to install the pins at a bit different locations, the trigger can be great without any issues of engaging safety.

So the latest upgrade regarding which I uploaded the video yesterday is about changing the angle of wheel sear, using light trigger return spring and using lighter sprung ball detent plunger.

Please note that all modifications made to the triggers needs HIGH PRECISION to avoid any accident.

It's not recommended for common users who don't understand the cause and effect of the mechanism in depth.

Here is my latest video below regarding improving Impact trigger to match grade level.

Bhaur

Upvote 0

I tried Facebook for Daniele and can't connect, and Youtube he's there but the email contact that's listed won't work.Has anyone purchased an aftermarket "match grade" trigger for M3 or Panthera? They are apparently available from Daniele Rizzotto (Facebook and Youtube) as well as mubhaur (AGN and Youtube). If so, please let us all know what you think. Also, is an FX match grade trigger available from any other source?

I sure would like to get in touch withh him if you have any other ideas to try?!

Thanks for your time!

Upvote 0

In fact in order to find a spring of required tension, I got many springs of various dia, wire thickness and tempering.Thanks for your reply. I subscribe to your channel and I saw your new video this morning. Too bad you cannot export your trigger - I would love to try it! I undeyjow you used heat to make the spring ball detent lighter. Where did you obtain the lighter trigger return spring? Again thank you for your work and posts on YouTube.

We don't find good springs here in my country. Hence I visit to a shop that sells tiny parts came there in result of ship braking.

In those used tiny parts, the tiny springs of various tension are also there.

Then I apply trial and testing method and also cut them to the required length.

The spring that works as per my need, is installed.

So it's difficult to get a few identical springs.

But if any manufacturer want to make refinements to OEM trigger, such springs may be sourced or may be got made to order.

Upvote 0

If you find him on Facebook you can message him even if you are not friended. Also, here's his Youtube channel - can probably message him here also.I tried Facebook for Daniele and can't connect, and Youtube he's there but the email contact that's listed won't work.

I sure would like to get in touch withh him if you have any other ideas to try?!

Thanks for your time!

Upvote 0

Thank you. I have an assortment of springs - some small and light. I may experiment!In fact in order to find a spring of required tension, I got many springs of various dia, wire thickness and tempering.

We don't find good springs here in my country. Hence I visit to a shop that sells tiny parts came there in result of ship braking.

In those used tiny parts, the tiny springs of various tension are also there.

Then I apply trial and testing method and also cut them to the required length.

The spring that works as per my need, is installed.

So it's difficult to get a few identical springs.

But if any manufacturer want to make refinements to OEM trigger, such springs may be sourced or may be got made to order.

Upvote 0

OK, Thanks!If you find him on Facebook you can message him even if you are not friended. Also, here's his Youtube channel - can probably message him here also.

Upvote 0

I really do agree especially if it's adjusted properly. I've got mine set as a single stage at about 12 ounces. Not good for field work but my shooting is from the bench.IHO I don’t see anything wrong with the factory FX trigger.

Upvote 0

Not to belittle anyone's contribution to this hobby, just saw the trigger design of Panthera.If you find him on Facebook you can message him even if you are not friended. Also, here's his Youtube channel - can probably message him here also.

It's trigger design is very much like FX Royal series guns.

In this kind of upper sear, the trigger is inherently easier to be adjusted as per requirement.

A small area of hook type sear comes into engagement with the wheel type sear.

Overall angle of upper sear is way better than of Impact. Hence it is easier to improve the OEM Panthera trigger.

Following are pics of Royal 400 trigger vs Panthera trigger vs Impact trigger.

Following is Royal 400 trigger

Following is Panthera trigger

Following is Impact trigger

Bhaur

Upvote 0

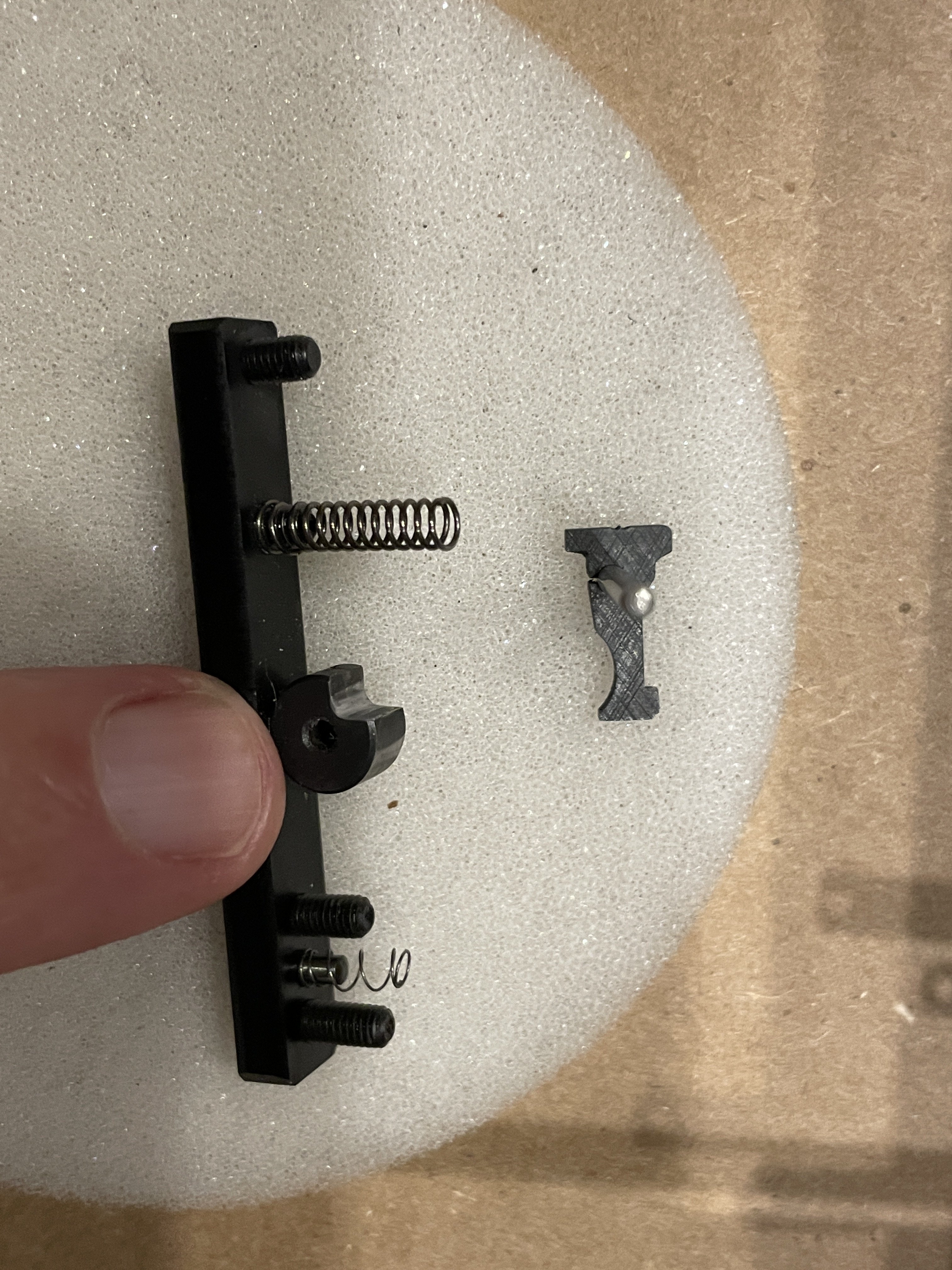

As there is good info in this thread, I thought I’d share another variant of the FX trigger design - this is from my FX Dreamline Power Pup (very cool high powered FX rifle - 80cc plenum - bigger than Impact M3 plenum)

This is a rear cocking bullpup, and apparently the FX trigger design is so bad, that FX gave up and didn’t even bother to install their fake 2nd stage (ball on spring) and try to get it to work, lol.

They should not advertise the PowerPup as having a “two stage match grade trigger” - a slogan used in their marketing to date.

Note the strange little spring on the right side of the trigger assembly. Have not seen this before in any FX.

-Ed

This is a rear cocking bullpup, and apparently the FX trigger design is so bad, that FX gave up and didn’t even bother to install their fake 2nd stage (ball on spring) and try to get it to work, lol.

They should not advertise the PowerPup as having a “two stage match grade trigger” - a slogan used in their marketing to date.

Note the strange little spring on the right side of the trigger assembly. Have not seen this before in any FX.

-Ed

Upvote 0

Nor I, the definition of a two stage trigger is based on function, not on specific design aspects. So the adjective "fake" isn't reasonable.IHO I don’t see anything wrong with the factory FX trigger.

Last edited:

Upvote 0

Then I made a new design of trigger. It was very good but everyone couldn't adjust it right. I uploaded the video and also shared it with Fredrik.

This design was good but it had one drawback. The safety couldn't work in this new design.

It was good for target shooters only.

Initially I provided a couple to two shooters but this trigger needed very fine adjustments in each gun to work properly and it became difficult for user's to make it work right.

Then I stopped providing this design. The videos of this design are also uploaded on my channel.

Making it hard to adjust has to do with the changes you made to the design as far as I can see on video.

You've changed the green part in this design and that is the part that should not have been changed in it's function since that is the part that is going to make this an improved trigger. I've designed/drawn it such that you can set the sear engagement externally without having to take it apart and against the existing pin that is already in the impact. Whatever is done to the orange bar doesn't really matter since that is all first stage and does not touch the sear if set at least somewhat correctly. In this idea/design the safety will also work

The way that groen part should be set to make it work as sharp as it could be: cock the Impact and let the sear and searlink etc engage and don't touch the rest of the trigger -> start adjusting the set screw slowly in the green part up to the point the Impact shoots -> back out that screw about 1/8 turn and you have it set safely and sharply. Then you can do to the first stage part whatever you like as long as the adjustments don't move the green part until you're ready to shoot. In the way you've implemented it mubhaur it's hard to set that engagement/sharp setting so I can imagine people have a hard time understanding how it works and setting it correctly.

This design has been at FX already for over 4 years

I don't have the machinery available to produce it myself so good that Mubhaur made a version of it!

Upvote 0

Nor I, the definition of a two stage trigger is based on function, not on specific design aspects. So the adjective "fake" isn't reasonable.

They have a bit of a mediocre description of triggers in my opinion. My idea of a match grade two stage trigger is having a sear that does not move by the first stage and is only released when the first stage transitions to the second stage. The current FX trigger design the sear always moves when the trigger moves (except for the boss trigger assy partly) and a ball detent screw 'fakes' the stage separation by giving a clicky feel at some point.

Upvote 0

Yes as I do visit various websites related to airgunning and take any good ideas from there, I don't claim that the design is exclusively mine.Making it hard to adjust has to do with the changes you made to the design as far as I can see on video.

You've changed the green part in this design and that is the part that should not have been changed in it's function since that is the part that is going to make this an improved trigger. I've designed/drawn it such that you can set the sear engagement externally without having to take it apart and against the existing pin that is already in the impact. Whatever is done to the orange bar doesn't really matter since that is all first stage and does not touch the sear if set at least somewhat correctly. In this idea/design the safety will also work

View attachment 422565

The way that groen part should be set to make it work as sharp as it could be: cock the Impact and let the sear and searlink etc engage and don't touch the rest of the trigger -> start adjusting the set screw slowly in the green part up to the point the Impact shoots -> back out that screw about 1/8 turn and you have it set safely and sharply. Then you can do to the first stage part whatever you like as long as the adjustments don't move the green part until you're ready to shoot. In the way you've implemented it mubhaur it's hard to set that engagement/sharp setting so I can imagine people have a hard time understanding how it works and setting it correctly.

This design has been at FX already for over 4 yearsI've sent it to idea back then to FX and went to Sweden two years ago to discuss triggers (and test some other stuff), they listened to this design and they had some ideas of their own but for most applications the triggers are good enough so they don't really put time and effort into it. Other business has been more important to them, especially in the past year.

I don't have the machinery available to produce it myself so good that Mubhaur made a version of it!

Various inputs from various tuners were gathered while making this trigger.

Practically the extreme left adjuster screw in green part doesn't work and doesn't allow rest of the trigger parts work while in place.

So this practically became an issue in the design when installing and testing the trigger.

We did various changes in the design. Also installed a tiny spring to keep the green part pushed towards right side to ensure secure and consistent engagement of sear.

Since the extreme left adjuster screw locked the trigger, it wan necessary to remove it or remove the pin under it.

This caused the trigger not effective for safety button.

With this input you can further improve the design and we can mutually move forward on improving the best possible and functional design.

Upvote 0

I have not posted much on this site but am in the process of buying a Panthera ... Looking for a name and contact info where I can order a light trigger kit for the Panthera please. A friend shot his at our rimfire benchrest match last weekend and now I want one ... but I need a light trigger for it.

I do have an Impact MKII which shoots OK... but nothing like his Panthera... and no where close to rimfire accuracy (he was shooting .22 Altaros ATP King 40 Gr Slugs at about 930 and was nailing 10's and X's on the IR5050 card. He won both the IR5050 bbenchrest match and the long range silhouette match against some very experienced and well equipped rimfire shooters .. which I found very impressive and now want to get back into airguns) I stopped shooting the Impact because it has such a horrendous trigger , I cannot seem to get it adjusted to be lighter & could not get scores close to rimfire.

I tried his and did not have as good scores as did because I am more of a benchrest shooter and his factory trigger was horrendous as well ... am not really sure how heavy it was because I did not have a scale but felt like a 4 lbs trigger ... I would l not use this gun for hunting and I do not care about having a safety because I only shoot off a bench in benchrest matches or practice... so if the trigger kit has no safety, I do not care .. none of my benchrest guns have one ..

Also I could not figure out how to PM people on this forum?? Maybe because I am new I do not have this privileges ,, not sure ... I am not very good at modifying or polishing stuff so I prefer to just buy a trigger kit and put it in ... does mubhaur (above poster) or anybody else sell a trigger kit that makes this trigger in the 8 or so ounces or less?

I was very excited at the performance of the Panthera but if I cannot by a light trigger for it, I am not as excited .

All advice welcome on where I can get

I do have an Impact MKII which shoots OK... but nothing like his Panthera... and no where close to rimfire accuracy (he was shooting .22 Altaros ATP King 40 Gr Slugs at about 930 and was nailing 10's and X's on the IR5050 card. He won both the IR5050 bbenchrest match and the long range silhouette match against some very experienced and well equipped rimfire shooters .. which I found very impressive and now want to get back into airguns) I stopped shooting the Impact because it has such a horrendous trigger , I cannot seem to get it adjusted to be lighter & could not get scores close to rimfire.

I tried his and did not have as good scores as did because I am more of a benchrest shooter and his factory trigger was horrendous as well ... am not really sure how heavy it was because I did not have a scale but felt like a 4 lbs trigger ... I would l not use this gun for hunting and I do not care about having a safety because I only shoot off a bench in benchrest matches or practice... so if the trigger kit has no safety, I do not care .. none of my benchrest guns have one ..

Also I could not figure out how to PM people on this forum?? Maybe because I am new I do not have this privileges ,, not sure ... I am not very good at modifying or polishing stuff so I prefer to just buy a trigger kit and put it in ... does mubhaur (above poster) or anybody else sell a trigger kit that makes this trigger in the 8 or so ounces or less?

I was very excited at the performance of the Panthera but if I cannot by a light trigger for it, I am not as excited .

All advice welcome on where I can get

Upvote 0

D

Deleted member 54174

Guest

You need 7 more post before you can PM. Good luck finding a drop in. You will have to work on it yourself by changing the 1st stage spring, very carefully heating up the 2nd stage trigger screw to soften the internal spring and some polishing. I gave up on having a 2nd and just made it a great 4oz 1st stage.I have not posted much on this site but am in the process of buying a Panthera ... Looking for a name and contact info where I can order a light trigger kit for the Panthera please. A friend shot his at our rimfire benchrest match last weekend and now I want one ... but I need a light trigger for it.

I do have an Impact MKII which shoots OK... but nothing like his Panthera... and no where close to rimfire accuracy (he was shooting .22 Altaros ATP King 40 Gr Slugs at about 930 and was nailing 10's and X's on the IR5050 card. He won both the IR5050 bbenchrest match and the long range silhouette match against some very experienced and well equipped rimfire shooters .. which I found very impressive and now want to get back into airguns) I stopped shooting the Impact because it has such a horrendous trigger , I cannot seem to get it adjusted to be lighter & could not get scores close to rimfire.

I tried his and did not have as good scores as did because I am more of a benchrest shooter and his factory trigger was horrendous as well ... am not really sure how heavy it was because I did not have a scale but felt like a 4 lbs trigger ... I would l not use this gun for hunting and I do not care about having a safety because I only shoot off a bench in benchrest matches or practice... so if the trigger kit has no safety, I do not care .. none of my benchrest guns have one ..

Also I could not figure out how to PM people on this forum?? Maybe because I am new I do not have this privileges ,, not sure ... I am not very good at modifying or polishing stuff so I prefer to just buy a trigger kit and put it in ... does mubhaur (above poster) or anybody else sell a trigger kit that makes this trigger in the 8 or so ounces or less?

I was very excited at the performance of the Panthera but if I cannot by a light trigger for it, I am not as excited .

All advice welcome on where I can get

Upvote 0

Contact Daniele Rizzotto on Facebook. Here’s his video on YouTube:I have not posted much on this site but am in the process of buying a Panthera ... Looking for a name and contact info where I can order a light trigger kit for the Panthera please. A friend shot his at our rimfire benchrest match last weekend and now I want one ... but I need a light trigger for it.

I do have an Impact MKII which shoots OK... but nothing like his Panthera... and no where close to rimfire accuracy (he was shooting .22 Altaros ATP King 40 Gr Slugs at about 930 and was nailing 10's and X's on the IR5050 card. He won both the IR5050 bbenchrest match and the long range silhouette match against some very experienced and well equipped rimfire shooters .. which I found very impressive and now want to get back into airguns) I stopped shooting the Impact because it has such a horrendous trigger , I cannot seem to get it adjusted to be lighter & could not get scores close to rimfire.

I tried his and did not have as good scores as did because I am more of a benchrest shooter and his factory trigger was horrendous as well ... am not really sure how heavy it was because I did not have a scale but felt like a 4 lbs trigger ... I would l not use this gun for hunting and I do not care about having a safety because I only shoot off a bench in benchrest matches or practice... so if the trigger kit has no safety, I do not care .. none of my benchrest guns have one ..

Also I could not figure out how to PM people on this forum?? Maybe because I am new I do not have this privileges ,, not sure ... I am not very good at modifying or polishing stuff so I prefer to just buy a trigger kit and put it in ... does mubhaur (above poster) or anybody else sell a trigger kit that makes this trigger in the 8 or so ounces or less?

I was very excited at the performance of the Panthera but if I cannot by a light trigger for it, I am not as excited .

All advice welcome on where I can get

Upvote 0

D

Deleted member 54174

Guest

Yeah right. I went that route and never received my trigger. One excuse after another. I was lucky enough to get my money back. Stay away!Contact Daniele Rizzotto on Facebook. Here’s his video on YouTube:

Upvote 0