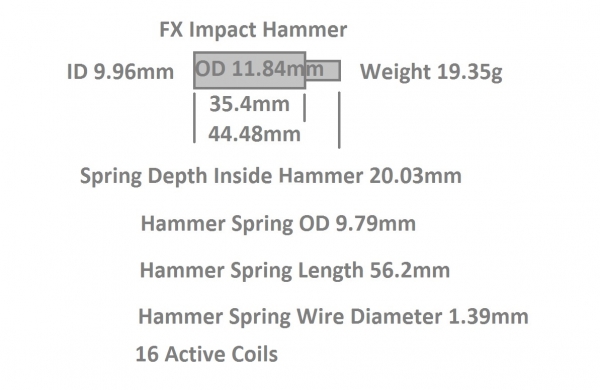

Here are the FX impact X hammer and spring specs for those who like to modify. These specs were measured from my .30 Impact X but I'm sure they are the same for all standard power calibers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FX Impact X Hammer and Spring Specs + Huma Regulator Problem

- Thread starter heavy-impact

- Start date

Need to know how many active coils the spring has to determine full specs. If its the identical one to the crown thread which has roughly 16 active coils that would make this spring rates at 22 lbs an inch...that just seems insane...

20 grams of hammer is SUPER light, if this is just a .177 only thing I understand but for .22 and .25 cal that is way low....what the heck is FX doing with overly lightened hammers that require crazy amounts of spring. I have tested personally similar setups from 25 gr hammers and very heavy springs to 50 gr hammers with half the spring and they perform equally, so why would I run the 25 gr hammer? To put it simply I don't, its in a box.

I guess the method of a VERY light hammer and VERY heavy spring does aid in reducing hammer bounce but...there are better ways to skin that cat, such as I have and MANY others have done with hammer debounce devices that don't require stupidly high spring rates to counter act the valve stem sending the hammer back flying into it to kill energy between bounces...meh

How much SPRUNG THROW does the fx impact have? If its only .25" then a 22 lb/in spring is only gonna be 5.5 lbs cocking force but if its .75" that same spring is 16.5 lb cocking force...so that makes a huge difference in determining how much of said spring is in actual use. Its preload also is required much I am sure that varies along with hammer throw depending on caliber settings.

a 3:1 cocking lever takes 16.5 lb back down to 5.5 lbs cocking force which is fine, and likely why many manufactures moved to side levers, in an attempt to run very heavy hammer springs with light hammers in an attempt to combat hammer bounce. JMO and observation but neither are required. Can run half the spring, twice the hammer weight, and a proper hammer 'de-bounce' device. JMO and observations based on my knowledge!

20 grams of hammer is SUPER light, if this is just a .177 only thing I understand but for .22 and .25 cal that is way low....what the heck is FX doing with overly lightened hammers that require crazy amounts of spring. I have tested personally similar setups from 25 gr hammers and very heavy springs to 50 gr hammers with half the spring and they perform equally, so why would I run the 25 gr hammer? To put it simply I don't, its in a box.

I guess the method of a VERY light hammer and VERY heavy spring does aid in reducing hammer bounce but...there are better ways to skin that cat, such as I have and MANY others have done with hammer debounce devices that don't require stupidly high spring rates to counter act the valve stem sending the hammer back flying into it to kill energy between bounces...meh

How much SPRUNG THROW does the fx impact have? If its only .25" then a 22 lb/in spring is only gonna be 5.5 lbs cocking force but if its .75" that same spring is 16.5 lb cocking force...so that makes a huge difference in determining how much of said spring is in actual use. Its preload also is required much I am sure that varies along with hammer throw depending on caliber settings.

a 3:1 cocking lever takes 16.5 lb back down to 5.5 lbs cocking force which is fine, and likely why many manufactures moved to side levers, in an attempt to run very heavy hammer springs with light hammers in an attempt to combat hammer bounce. JMO and observation but neither are required. Can run half the spring, twice the hammer weight, and a proper hammer 'de-bounce' device. JMO and observations based on my knowledge!

Upvote 0

The X and pre-X hammers must be the same, because those are the same (within thousandths of an inch) as what I documented on my pre-X rifle. The new CNC mill and I are still getting to know each other, but I have managed to make hammer weights similar to what Ernest showed in aluminum (3g), stainless (8g) and brass (9g). They will have to have some spring pre-load, but that amount is variable. I hope to do some testing on these very soon to get more power at higher reg pressures.

Cheers,

Rusty

Cheers,

Rusty

Upvote 0

The X and pre-X hammers must be the same, because those are the same (within thousandths of an inch) as what I documented on my pre-X rifle. The new CNC mill and I are still getting to know each other, but I have managed to make hammer weights similar to what Ernest showed in aluminum (3g), stainless (8g) and brass (9g). They will have to have some spring pre-load, but that amount is variable. I hope to do some testing on these very soon to get more power at higher reg pressures.

Cheers,

Rusty

There's a much simpler way of testing. Make lead disks of different weights, tap/form them into place inside the hammer and drill the center hole. I just added 3.25g to mine in about 10 minutes. The lead disk is 4.47mm thick so that will add more preload. I included spring depth in the hammer specs so this could be calculated. Up to 10mm could be machined out of the solid part of the hammer to be replaced with heavier material if you want to lose the preload. I'm reassembling the gun now and will be testing soon.

Upvote 0

You guys are running as low as 3, 8, and 9 gr of hammer? Stock is 20? Or are those weights to ADD hammer weight, that would make more sense... Also MDS Nylon is far superior to metal hammers IMO and I highly recommend trying it, as it is self lubricating, even in a rifle without a drop sear one can use a primarily MDS nylon hammer with a steel/brass/aluminum insert on the area that makes contact with the sear...MDS nylon will without question provide more consistent hammer strikes than any metal on metal configuration would...lower coefficient of friction...You generally have to add a metal core of your choice to get the proper weight with MDS Nylon.

Momentum is conserved, KE is not (entirely). To run such LOW momentum and HIGH KE with overly sprung hammers is not ideal IMO. Momentum does more work in opening the valve than KE because of conservation...The only real benefit in a properly tuned rifle to run such configuration is reducing hammer lock time and overall rifle lock time from trigger pull to pellet exit, which is a rather extreme approach, because one can just go electronic and remove almost all hammer lock time...The benefit in a non-properly tuned rifle (hammer preloaded against valve when uncocked is a fine example) is aiding in reducing hammer bounce due to losing nearly all hammer energy upon contact with the valve.

So what is the logic and reason behind running such lightened hammers and such sprung hammers? Seems like a band aid to hammer bounce more than anything...one I am glad I have an alternate solution for that doesn't require such heavy springs. JMO

-Matt

Momentum is conserved, KE is not (entirely). To run such LOW momentum and HIGH KE with overly sprung hammers is not ideal IMO. Momentum does more work in opening the valve than KE because of conservation...The only real benefit in a properly tuned rifle to run such configuration is reducing hammer lock time and overall rifle lock time from trigger pull to pellet exit, which is a rather extreme approach, because one can just go electronic and remove almost all hammer lock time...The benefit in a non-properly tuned rifle (hammer preloaded against valve when uncocked is a fine example) is aiding in reducing hammer bounce due to losing nearly all hammer energy upon contact with the valve.

So what is the logic and reason behind running such lightened hammers and such sprung hammers? Seems like a band aid to hammer bounce more than anything...one I am glad I have an alternate solution for that doesn't require such heavy springs. JMO

-Matt

Upvote 0

You guys are running as low as 3, 8, and 9 gr of hammer?

-Matt

Where did you get that ??? it's being added to the hammer internally.

Upvote 0

You guys are running as low as 3, 8, and 9 gr of hammer?

-Matt

Where did you get that ??? it's being added to the hammer internally.

I corrected my post as I misinterpreted his post thinking he was running those hammer weights not adding that weight to the 20 gr hammer. Makes more sense now!

Upvote 0

You guys are running as low as 3, 8, and 9 gr of hammer?

-Matt

Where did you get that ??? it's being added to the hammer internally.

I corrected my post as I misinterpreted his post thinking he was running those hammer weights not adding that weight to the 20 gr hammer. Makes more sense now!

You also have to account for the momentum of that long and realatvely heavy valve rod on the impact.

Upvote 0

Simple formula for estimating a good hammer weight requirement based on your power level...its very simple and scales well through all calibers...+ or - 10% of said result works great as well.

So for example a 12 FPE rifle can run as low as 20 gr hammer, and a 100 FPE rifle can run up to 72 gr and both should function fine provided adequate spring, which should be within reason with this formula. I consider all the results from this formula 'light weight' per the application...JMO, for middle to heavy weight I would use 10 as the multiplier.

SQRT(FPE)*6.6

Using the above formula my highly modified bolt actioned rifle can be cocked with my pinky finger on a 60 FPE tune.

So for example a 12 FPE rifle can run as low as 20 gr hammer, and a 100 FPE rifle can run up to 72 gr and both should function fine provided adequate spring, which should be within reason with this formula. I consider all the results from this formula 'light weight' per the application...JMO, for middle to heavy weight I would use 10 as the multiplier.

SQRT(FPE)*6.6

Using the above formula my highly modified bolt actioned rifle can be cocked with my pinky finger on a 60 FPE tune.

Upvote 0

You guys are running as low as 3, 8, and 9 gr of hammer?

-Matt

Where did you get that ??? it's being added to the hammer internally.

I corrected my post as I misinterpreted his post thinking he was running those hammer weights not adding that weight to the 20 gr hammer. Makes more sense now!

You also have to account for the momentum of that long and realatvely heavy valve rod on the impact.

Are you speaking about the valve stem protruding the valve that the hammer makes contact with? Regardless of its length or how much it sticks out valve lift is going to be the same regardless of its length. If its something else then I am unfamiliar with said rod.

Upvote 0

I haven't been able to do any testing due to the cold and rain but I just went out and shot a few over the chronograph out of curiosity.

.30 impact 700mm, 5.82 titanium valve seat,Huma HP regulator Huma regulator FAILED and Huma offers no help.

3.25 grams of lead added to the hammer

160 bar

44.75gn JSB averaging 960 fps 92 ft/lb

51.2gn HP cast by Loren averaging 925 fps 97 ft/lb

It's cold and drizzling rain so I can't shoot targets but the weather should clear soon and we'll see what it does. I may do some port work next week after the first round of testing.

.30 impact 700mm, 5.82 titanium valve seat,

3.25 grams of lead added to the hammer

160 bar

44.75gn JSB averaging 960 fps 92 ft/lb

51.2gn HP cast by Loren averaging 925 fps 97 ft/lb

It's cold and drizzling rain so I can't shoot targets but the weather should clear soon and we'll see what it does. I may do some port work next week after the first round of testing.

Upvote 0

Are you speaking about the valve stem protruding the valve that the hammer makes contact with? Regardless of its length or how much it sticks out valve lift is going to be the same regardless of its length. If its something else then I am unfamiliar with said rod.

View attachment 1542986626_10562579455bf81b829b7633.81340447_FX Impact X Part List.pdf

C4 with C1,B26 and B28 attached. It's about a foot long.

Upvote 0

I see...well..understand that the momentum of that is minimized. Momentum is based on velocity and mass. Mass reduces velocity...so a heavy long valve stem will move slower than a shorter lighter one. Also the lift as I stated is the same as a conventional length valve stem, as low as .05"~ and upwards of .1"~...its unlikely your valve stem upon closure is gaining much momentum, which is ENTIRELY halted and reduced to 0 once contact with valve seat is made...the use of a long valve stem such as the fx impact does NOT give basis to use a very light hammer and heavy spring, just as they do in the crown which does NOT have an extremely long / heavy valve stem...

I already pointed out the primary use for an OVERLY light hammer and REALLY heavy spring, its to aid in reducing hammer bounce, its the only approach fx models take unless I am missing something?

I already pointed out the primary use for an OVERLY light hammer and REALLY heavy spring, its to aid in reducing hammer bounce, its the only approach fx models take unless I am missing something?

Upvote 0

I feel like you're arguing a design point while I'm only stating what I need to adjust to get the desired result. These are the parts I have to work with and I'm taking the easiest route to reach my goal. I post the results so that others can copy my example while keeping it simple and using only common hand tools.

Upvote 0

I finally hit the 100 ft/lb mark with JSB 50.15 at 946 fps after porting the valve tube, rear block, barrel transfer port and pellet probe.

The Huma regulator failed a few days ago and Huma offers no help. So much for their customer service. I put the same 14 washer stack from the Huma onto the FX regulator in the same HP configuration and it's working well so far. I need more hammer weight now since I'm not getting much improvement above 160bar.

The Huma regulator failed a few days ago and Huma offers no help. So much for their customer service. I put the same 14 washer stack from the Huma onto the FX regulator in the same HP configuration and it's working well so far. I need more hammer weight now since I'm not getting much improvement above 160bar.

Upvote 0

I finally hit the 100 ft/lb mark with JSB 50.15 at 946 fps after porting the valve tube, rear block, barrel transfer port and pellet probe.

The Huma regulator failed a few days ago and Huma offers no help. So much for their customer service. I put the same 14 washer stack from the Huma onto the FX regulator in the same HP configuration and it's working well so far. I need more hammer weight now since I'm not getting much improvement above 160bar.

Great work, that's a shame your reg failed and Huub hasn't offered any help. I measured my hammer spring on Royale and the specs match this one. I've always wondered if the Boss was capable of reaching 100fpe as well. Great tuning HI

Upvote 0

I finally hit the 100 ft/lb mark with JSB 50.15 at 946 fps after porting the valve tube, rear block, barrel transfer port and pellet probe.

The Huma regulator failed a few days ago and Huma offers no help. So much for their customer service. I put the same 14 washer stack from the Huma onto the FX regulator in the same HP configuration and it's working well so far. I need more hammer weight now since I'm not getting much improvement above 160bar.

Great work, that's a shame your reg failed and Huub hasn't offered any help. I measured my hammer spring on Royale and the specs match this one. I've always wondered if the Boss was capable of reaching 100fpe as well. Great tuning HI

Huma has replied to my email but nothing helpful. I've done everything possible to get the regulator working again but it won't let any air pass with 14 washers and 13 blows the piston o-ring out of it's bore. They suggested trying 16 washers but that would be too long for the piston.

Upvote 0

Sure seems like FX engineers would have considered such hammer weight/spring force points in designing the gun. Maybe improvements can be made but the guns do seem to work very well for most people. One seeming advantage to lighter hammer/heavier spring would be possibly faster lock time which might aid accuracy.

Upvote 0

I finally hit the 100 ft/lb mark with JSB 50.15 at 946 fps after porting the valve tube, rear block, barrel transfer port and pellet probe.

The Huma regulator failed a few days ago and Huma offers no help. So much for their customer service. I put the same 14 washer stack from the Huma onto the FX regulator in the same HP configuration and it's working well so far. I need more hammer weight now since I'm not getting much improvement above 160bar.

Hi Heavy Impact. Try less washers on you Huma not more. Also empty your bottle on the gun and fill very slowly to start from your fill station.

The hole that goes through the piston on the huma is on the side of the piston. If it is pushed down by the air pressure before air gets into the regulated side to push the piston into the housing the hole on the side will end up under the last oring and you’ll get no reg pressure. Make sure when you put it in the gun the piston is as far into the housing as possible. Also just tighten it down a ’twick’ more.

Hope that makes sense

Michael

Upvote 0

Sure seems like FX engineers would have considered such hammer weight/spring force points in designing the gun. Maybe improvements can be made but the guns do seem to work very well for most people. One seeming advantage to lighter hammer/heavier spring would be possibly faster lock time which might aid accuracy.

How much can you move your reticle in 3 ms? Imperceivable...I would not contribute a 3ms lower lock time to better accuracy...but to each their own. I've done the math and its too insignificant to be of concern.

I've THOROUGHLY tested lighter hammer weights, there is NO difference or benefit from them, they only require more spring to get the job done...spring/hammer weight on the EXTREME ends be them light or heavy may see subtle differences with efficiency / lock time BUT the range of ideal weight is quite broad and its better to be on the heavier side to allow lighter springs which reduce cocking effort. If you have no problem cocking 15-20+ lb springs then enjoy, but I personally don't, even 7.7 lb springs I run are no breeze. My most comfortable spring to cock is the 5 lb spring that I am limited to 30~ FPE with. It is like BUTTER.

-Matt

Upvote 0