Hi Guys,

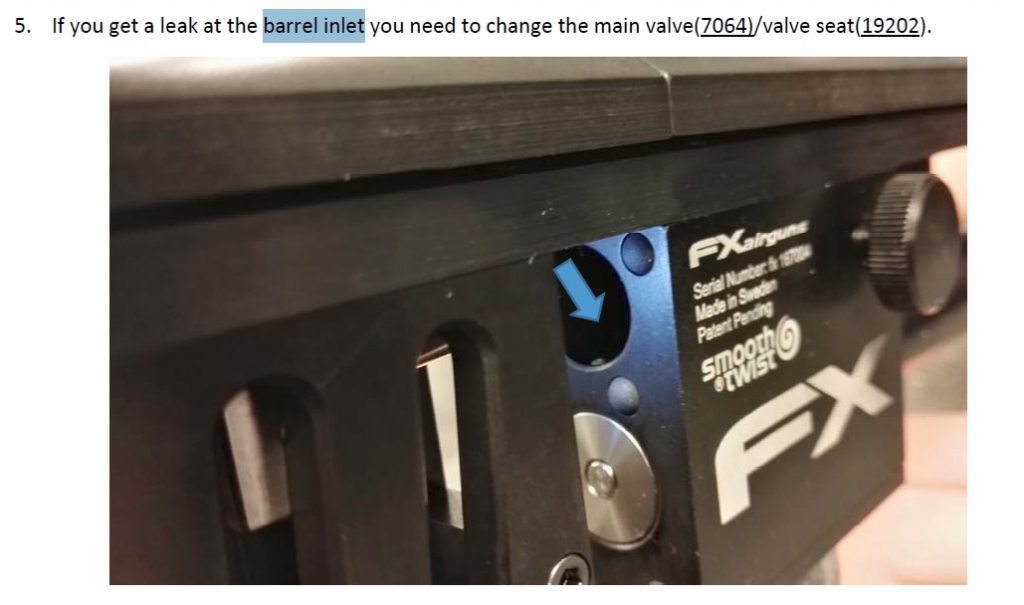

I found my barrel inlet is leaking the air. And check the FX trouble shooting manual. It said that was main valve(7064)/valve seat(19202) problem.

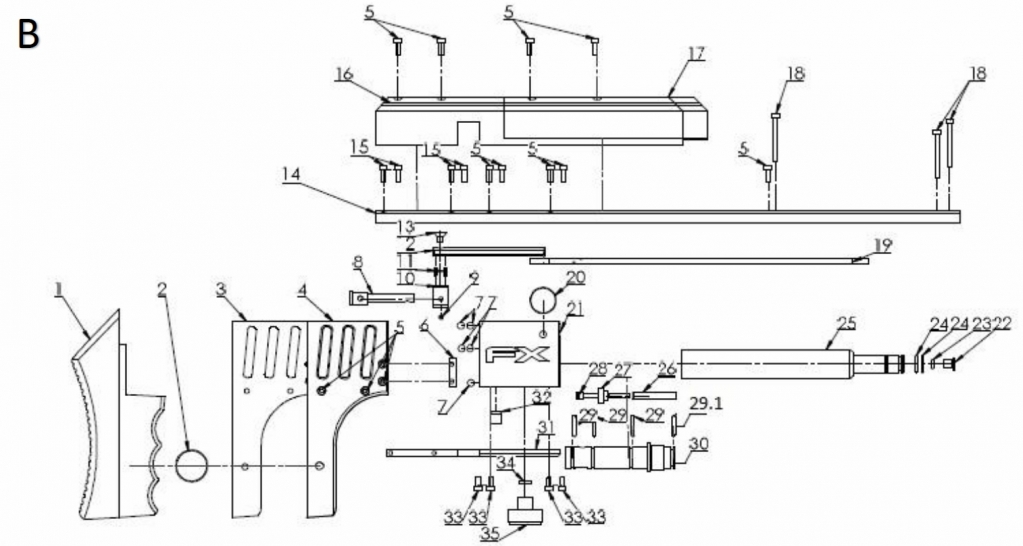

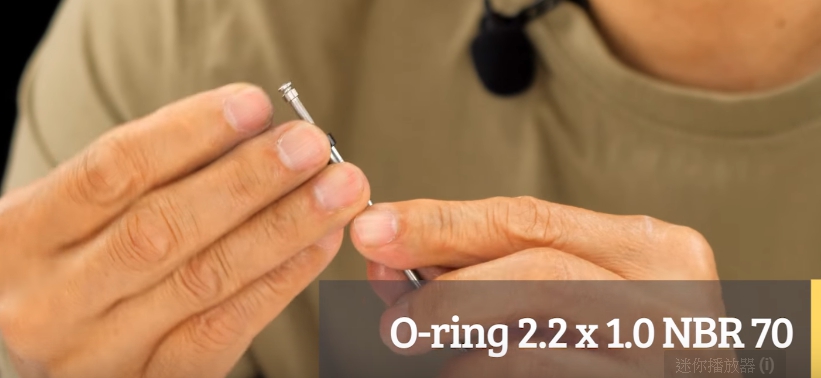

I replace all the valve housing(B29 & B29.1) & valve seat oring and rod oring(2.2x1.0).

But it still is leaking. I even changed the new valve housing and valve seat. It doesn't work.

Please help.

I found my barrel inlet is leaking the air. And check the FX trouble shooting manual. It said that was main valve(7064)/valve seat(19202) problem.

I replace all the valve housing(B29 & B29.1) & valve seat oring and rod oring(2.2x1.0).

But it still is leaking. I even changed the new valve housing and valve seat. It doesn't work.

Please help.