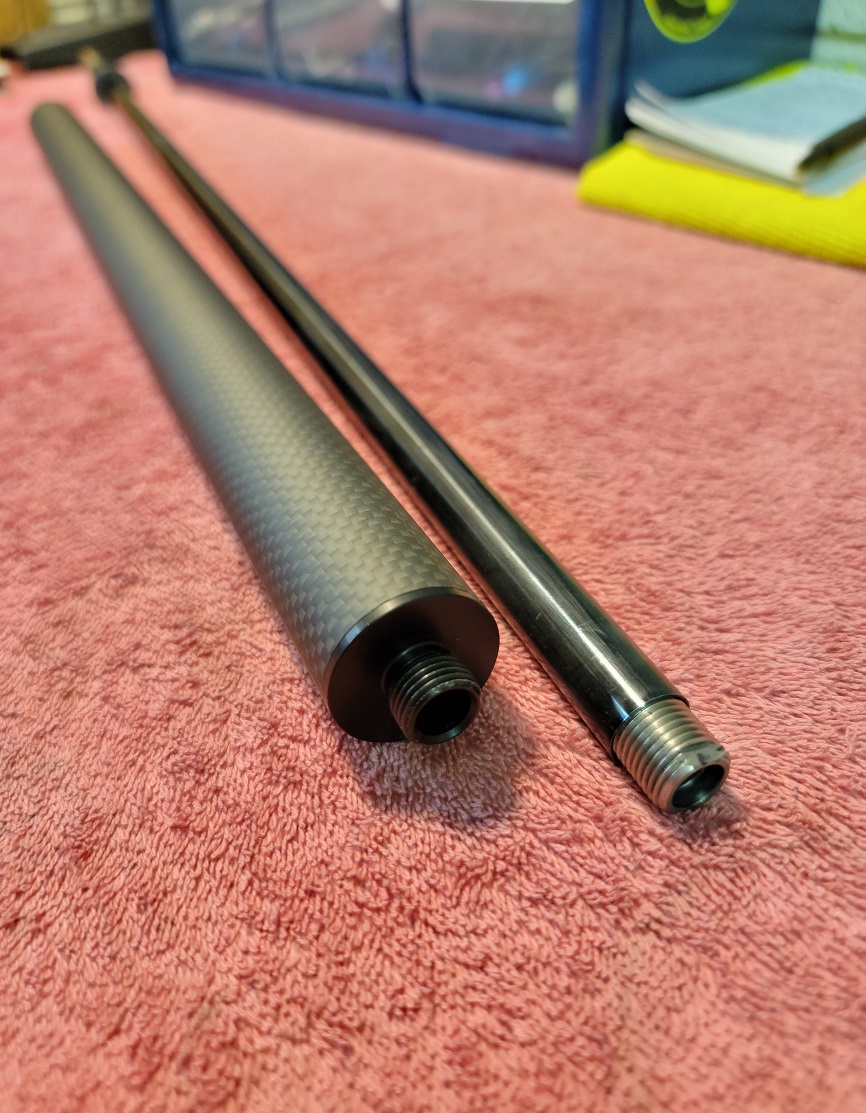

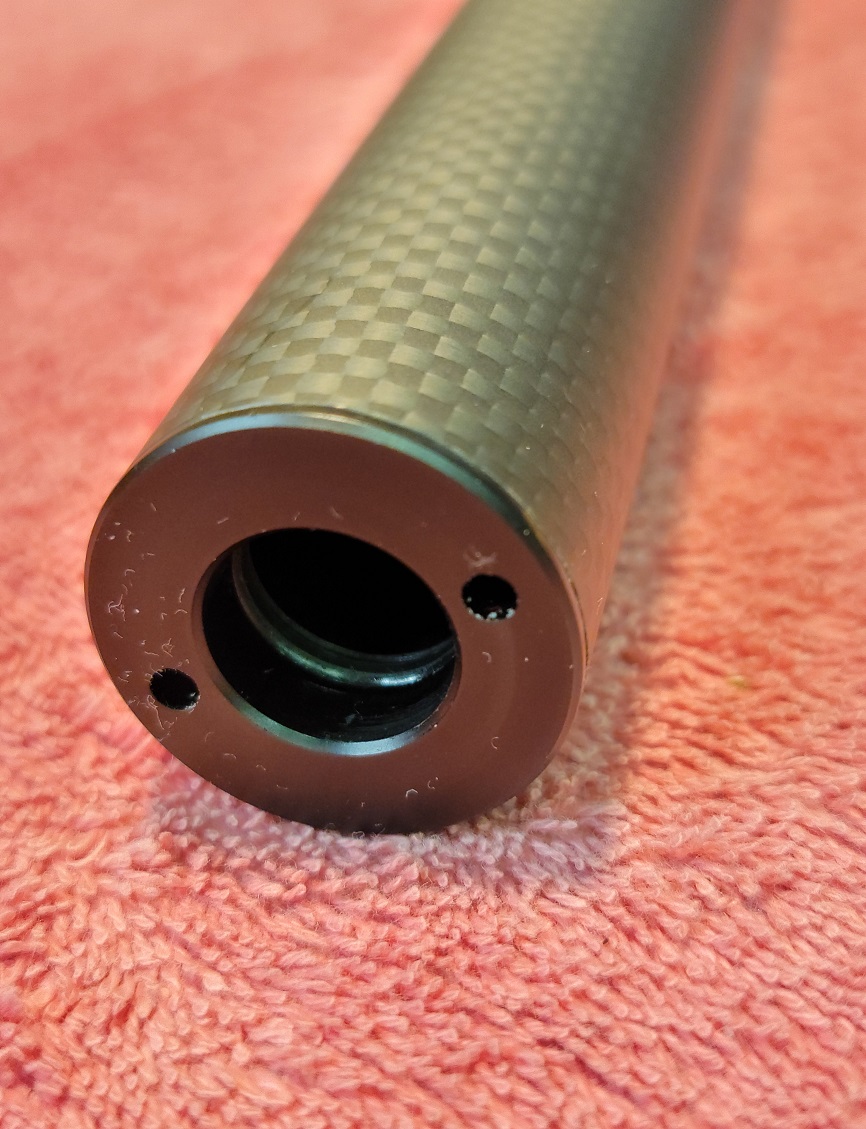

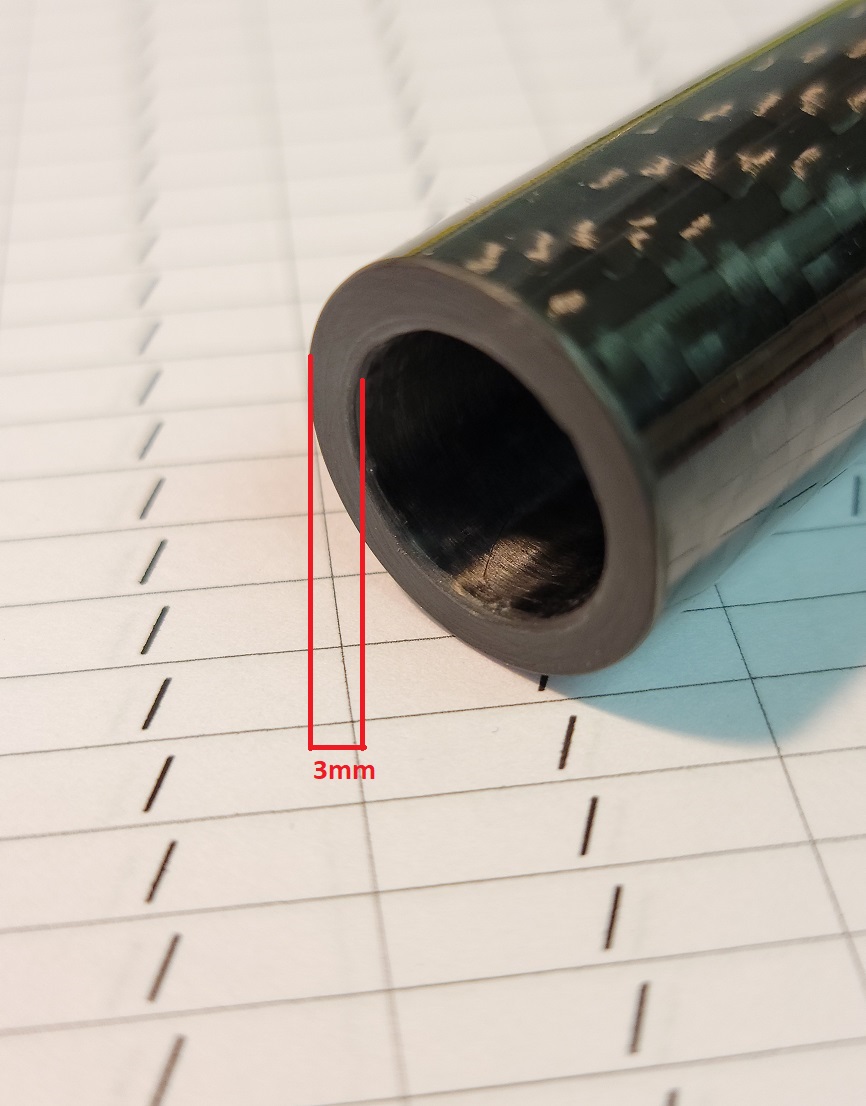

My experience mirrored that of the others here as well. Mine are unglued. I have made CF shrouds to go with sleeved liners too, using 15mm x 28mm. This combo seems to help harmonics and thermal stability too. On the Impact I added a 14mm x 20mm x 36mm spacer to snug up the shroud against the front support block. Next project is try Ernest Rowes 14mm x 20mm sleeve over my 600mm Impact barrel and make a tension cap @20mm OD with 1/2x20 threads to keep the CF positioned and allow for a moderator. I just received 14x20x1000 piece yesterday and will cut it down this weekend.

@blacksmith304, here are some photos and where I ordered the CF for the shroud.

https://smile.amazon.com/gp/product/B078MWLP2C/ref=ppx_yo_dt_b_asin_title_o07_s00?ie=UTF8&psc=1

Patrick

@blacksmith304, here are some photos and where I ordered the CF for the shroud.

https://smile.amazon.com/gp/product/B078MWLP2C/ref=ppx_yo_dt_b_asin_title_o07_s00?ie=UTF8&psc=1

Patrick

Upvote 0