Hi everybody.

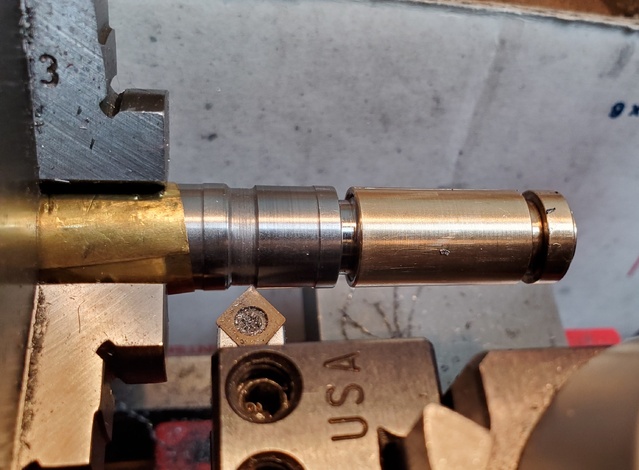

Recently i installed a installed a 700mm fx tension kit onto my .25 M3, not so much to see if i can increase accuracy as its already quite good but moreover to see if i can eliminate POI shift ( jury is still out on that one !).

Obviously removing the fx factory shroud and replacing it with the carbon fibre shroud and jam nut has ment that there is quite a increase in muzzle report as my current tune is pushing 41g slugs at 960fps ( some 80 odd ftlbs) and my 0DB sound mod is not coping very well. Has anyone else experienced this ? Im thinking of putting a carbon fibre tube cut to the appropriate and sliding that over the barrel tension tube to see if that soaks up any of the sound, next will be seeing about a different sound moderator, maybe a donny fl Ronin or something else.

Recently i installed a installed a 700mm fx tension kit onto my .25 M3, not so much to see if i can increase accuracy as its already quite good but moreover to see if i can eliminate POI shift ( jury is still out on that one !).

Obviously removing the fx factory shroud and replacing it with the carbon fibre shroud and jam nut has ment that there is quite a increase in muzzle report as my current tune is pushing 41g slugs at 960fps ( some 80 odd ftlbs) and my 0DB sound mod is not coping very well. Has anyone else experienced this ? Im thinking of putting a carbon fibre tube cut to the appropriate and sliding that over the barrel tension tube to see if that soaks up any of the sound, next will be seeing about a different sound moderator, maybe a donny fl Ronin or something else.