This is an update to some older posts of mine with new information about the defective bleed valve on the small Tuxing filter with the shutoff valve on it. If you buy this part, be sure to replace the bleed valve assembly with a better built bleed valve so as to not have a dangerous situation where the bleed screw can shoot out of the fitting under pressure like mine did.

If you want to be able to keep remove a filled gun from the fill whip without having to dump all the air in your water trap / filter just add these inexpensive components and you are good to go.

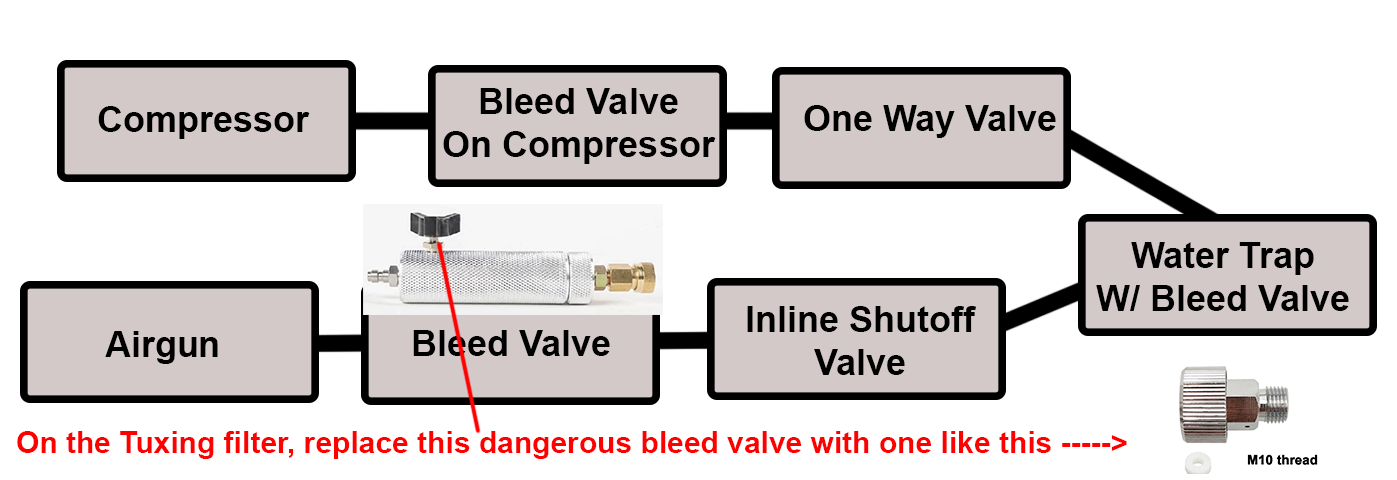

Diagram of where everything goes.

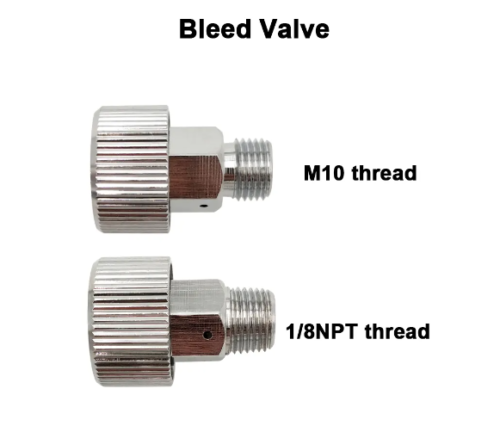

As noted above, be sure to replace the defective bleed valve on the silver Tuxing filter with something like this. I think that mine ended up being M10 but you never know what you are going to get from stuff off Aliexpress. Check it first.

Link to the part on eBay.

With all those items in place you can remove guns / tanks from the setup without losing pressure in your water trap AND restart your compressor with no load on it, saving quite a bit of time when filling multiple items in a row vs bleeding out the water trap every time. My double tube water trap takes longer to fill than most of my guns! Now there is no more waiting for it to fill.

Disclaimer: This post is for informational purposes only. Use these parts and instructions at your own risk. I am not stating that this is known to be a safe setup or parts. Working with high pressure air / HPA is potentially lethal. You are ultimately responsible to make sure everything is properly configured and you are using safety precautions.

If you want to be able to keep remove a filled gun from the fill whip without having to dump all the air in your water trap / filter just add these inexpensive components and you are good to go.

| | 6000 PSI needle valve for $15 on Amazon Intall this just before the shutoff valve as shown in the diagram. Several other options out there but this was the least expensive I found and it was rated at 6000 psi. It has been working well for many months. Something with a lever handle would be easier to turn off. |

| One way foster fittings are about $8. Just add the appropriate quick connector to install where shown on the diagram. I ended up with a male to male to match my hoses. | |

| The small Tuxing silver water trap with a bleed valve is $26.xx with a whip on Aliexpress. $39 without a whip on Amazon. Installed at the very and of the line as shown on the diagram. The bleed valve on mine FAILED and was fired into my hand with significant force. Be sure to replace it for your own safety, or use something else for a bleed valve. | |

Diagram of where everything goes.

As noted above, be sure to replace the defective bleed valve on the silver Tuxing filter with something like this. I think that mine ended up being M10 but you never know what you are going to get from stuff off Aliexpress. Check it first.

Link to the part on eBay.

With all those items in place you can remove guns / tanks from the setup without losing pressure in your water trap AND restart your compressor with no load on it, saving quite a bit of time when filling multiple items in a row vs bleeding out the water trap every time. My double tube water trap takes longer to fill than most of my guns! Now there is no more waiting for it to fill.

Disclaimer: This post is for informational purposes only. Use these parts and instructions at your own risk. I am not stating that this is known to be a safe setup or parts. Working with high pressure air / HPA is potentially lethal. You are ultimately responsible to make sure everything is properly configured and you are using safety precautions.

Last edited: