I have rebuilt 4 FWB model 65 pistols over the last couple of years. Feinwerkbau states no lube is needed In period advertising and maintenance instructions. I replaced the buffers and breach seal and rubbed a little dry moly powder into the compression ring and piston skirt as I have read that’s the permanent lube added at the factory. My question is all 4 had varying amounts of grease on the springs. From that I am guessing when FWB says dry they mean piston and ring and not the spring. I just received one from the Netherlands and plan To rebuild it this weekend. This will be the first one that needed a spring. I plan to lube the spring with a small amount of Vortek grease I have left over from tuning kits. Any opinions on if these left the factory with grease on the springs or are they truly dry lubed only?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FWB Feinwerkbau model 65 spring lube?

- Thread starter rokonman

- Start date

FWB has their own grease-lube but seeing that the spring and the cylinder do not get together i see no reason to not give the spring a very little lube

i did a FWB 90 5 years ago and used Ultimox 226 on the piston ring and spring and as it was the first one i ever did it was a pain to do

when they say very little and you did do just that it was too much

beside the sledge system and the little shims and e-c clips, the rear sight was the hardest part, getting that damn thing on with just two hands

if your last rebuilds worked keep doing what your doing

we all do our rebuilds a little different if in the end everything works, well i guess we did our job

i did a FWB 90 5 years ago and used Ultimox 226 on the piston ring and spring and as it was the first one i ever did it was a pain to do

when they say very little and you did do just that it was too much

beside the sledge system and the little shims and e-c clips, the rear sight was the hardest part, getting that damn thing on with just two hands

if your last rebuilds worked keep doing what your doing

we all do our rebuilds a little different if in the end everything works, well i guess we did our job

Upvote 0

I wish the factory would say what they use. I have rebuilt guns that have never been rebuilt and the factory is definitely putting some kind of lube on them when they are built.

Upvote 0

Not the 60 overall but looking seems the spring just use common springer lubing stuff. Like here are black tar used ..

https://www.pyramydair.com/blog/2010/11/a-shrine-built-for-a-feinwerkbau-124-part-13/

Matter of fact seems jm's lubes are used alot in a fbw...

I'm no expert on one but. I can't see a thin film of krytox on the seal as a assembly/ break in use to insure snag free first shots ..

I guess your getting a new gun out of the box and snatching it apart you'll then see kinda what the factory done .. maybe tell what's been used..?

https://www.pyramydair.com/blog/2010/11/a-shrine-built-for-a-feinwerkbau-124-part-13/

Matter of fact seems jm's lubes are used alot in a fbw...

I'm no expert on one but. I can't see a thin film of krytox on the seal as a assembly/ break in use to insure snag free first shots ..

I guess your getting a new gun out of the box and snatching it apart you'll then see kinda what the factory done .. maybe tell what's been used..?

Upvote 0

but the 65-80-90-150-300 do no use seals they use a steel piston ring to seal the piston in the cylinder

it i metal on metal with the life of the ring being in the 100,000 shot count or more

it i metal on metal with the life of the ring being in the 100,000 shot count or more

Yes the only seal is the breach seal the other 2 are buffers. As I mentioned above I add a very small amount of Dry moly powder to the ring and piston skirt. I have read that is the factory lube.but the 65-80-90-150-300 do no use seals they use a steel piston ring to seal the piston in the cylinder

it i metal on metal with the life of the ring being in the 100,000 shot count or more

Upvote 0

I think something's better then raw dog steel on steel. Dry moly or assembly lube like krytox something I'd feel needs to be there .. then what do I knowYes the only seal is the breach seal the other 2 are buffers. As I mentioned above I add a very small amount of Dry moly powder to the ring and piston skirt. I have read that is the factory lube.

Upvote 0

this is what they have for them never had any or knows what it looks like

and yes a little lube can hurt but too much can so if you lube it like a springer it could be way too much

lube on the piston and lube on the spring do not interact with each other.

https://www.pyramydair.com/product/feinwerkbau-special-gun-grease-for-fwb-pcps-4g?a=4912

and yes a little lube can hurt but too much can so if you lube it like a springer it could be way too much

lube on the piston and lube on the spring do not interact with each other.

https://www.pyramydair.com/product/feinwerkbau-special-gun-grease-for-fwb-pcps-4g?a=4912

Upvote 0

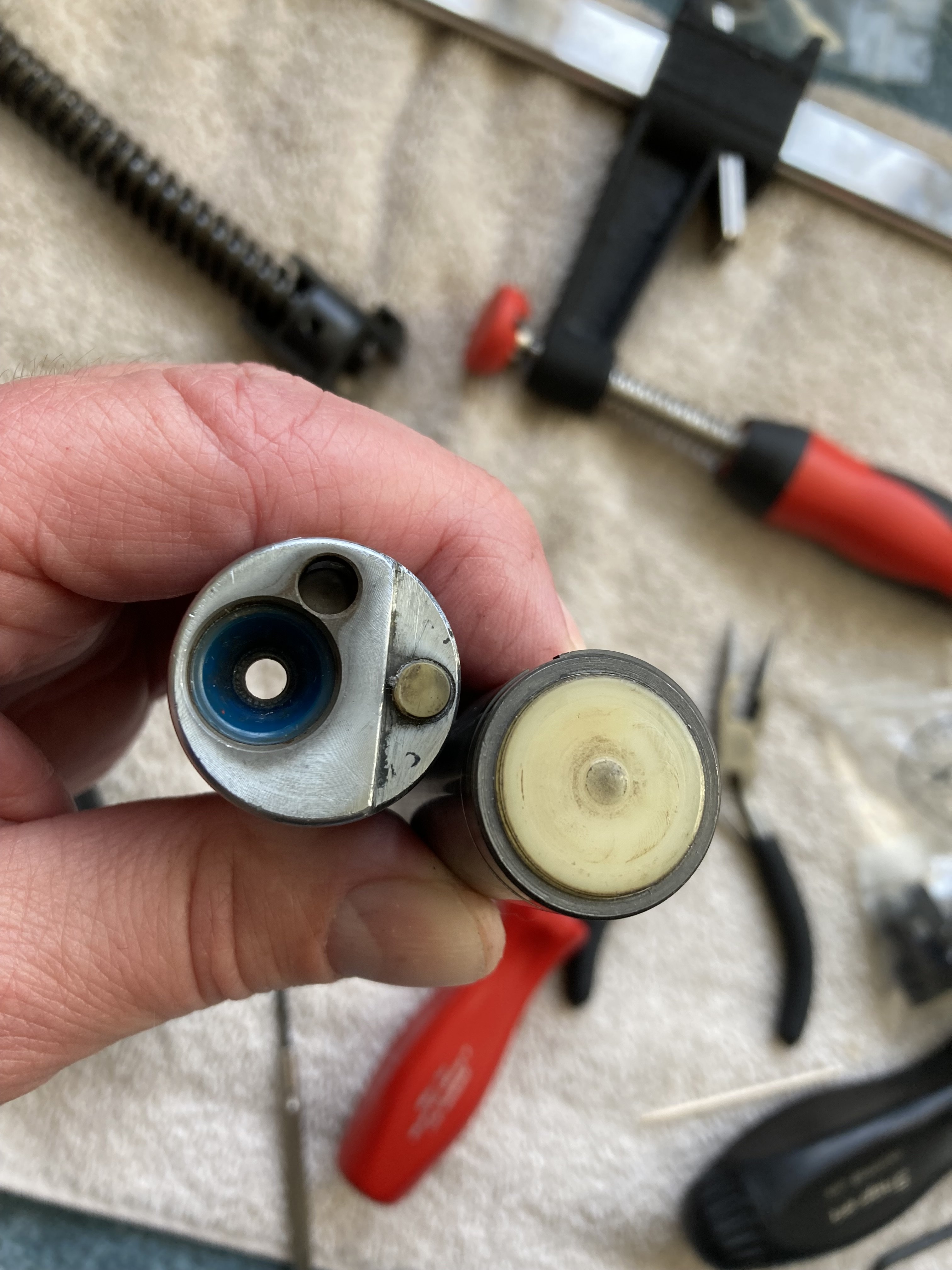

I am waking this old thread to let anyone that cares know I have a definitive answer. I just received a model 65 that has been shot very little and has never been apart. It was produced around 1980 and is the 2 spring version. The buffers are solid as new but I am replacing them along with the mainspring so it will be ready for another 40 years. Other than the dry moly on the piston and cylinder there is no factory spring lube. Both springs left the factory dry.

Attachments

Last edited:

Upvote 0

the small buffer and internal buffer are original but the breech seal has replaced

that is how i found my internal buffer in my model 90 but as with you changed it

two things i have heard the small buff, take a knife and make a small cut on the side to let the air escape to seat it and leave the gun overnight 24 hours so the breech seal seat in both make sense

that is how i found my internal buffer in my model 90 but as with you changed it

two things i have heard the small buff, take a knife and make a small cut on the side to let the air escape to seat it and leave the gun overnight 24 hours so the breech seal seat in both make sense

Upvote 0

Thanks for the advice. I have been slicing the small buffer since tripping over that info on one of these forums. I like the idea of letting the breach seal seat.the small buffer and internal buffer are original but the breech seal has replaced

that is how i found my internal buffer in my model 90 but as with you changed it

two things i have heard the small buff, take a knife and make a small cut on the side to let the air escape to seat it and leave the gun overnight 24 hours so the breech seal seat in both make sense

Upvote 0

I've re-built a couple.

Went with Teflon grease. Does not Diesel in the air pistol, does not attack the plastics and fine on the spring.

Keep it absolute minimal.

Went with Teflon grease. Does not Diesel in the air pistol, does not attack the plastics and fine on the spring.

Keep it absolute minimal.

Upvote 0