I pulled the stock off my Jnc stamped 124D because I wanted to try a different approach on the

the forearm fasteners. I made brass flat washers and used them under the external toothed

star washers but they still slowly came loose. I decided to try a #10 internal toothed lock washer

this time. In both attempts I used Vibra-Tite VC-3 on all three machine screw stock fasteners.

When I had the stock off I noticed the receiver lug screw didn't appear to be bottomed out. I checked

it and it was loose. Probably a good full turn loose ! Has anyone else had this problem? After getting

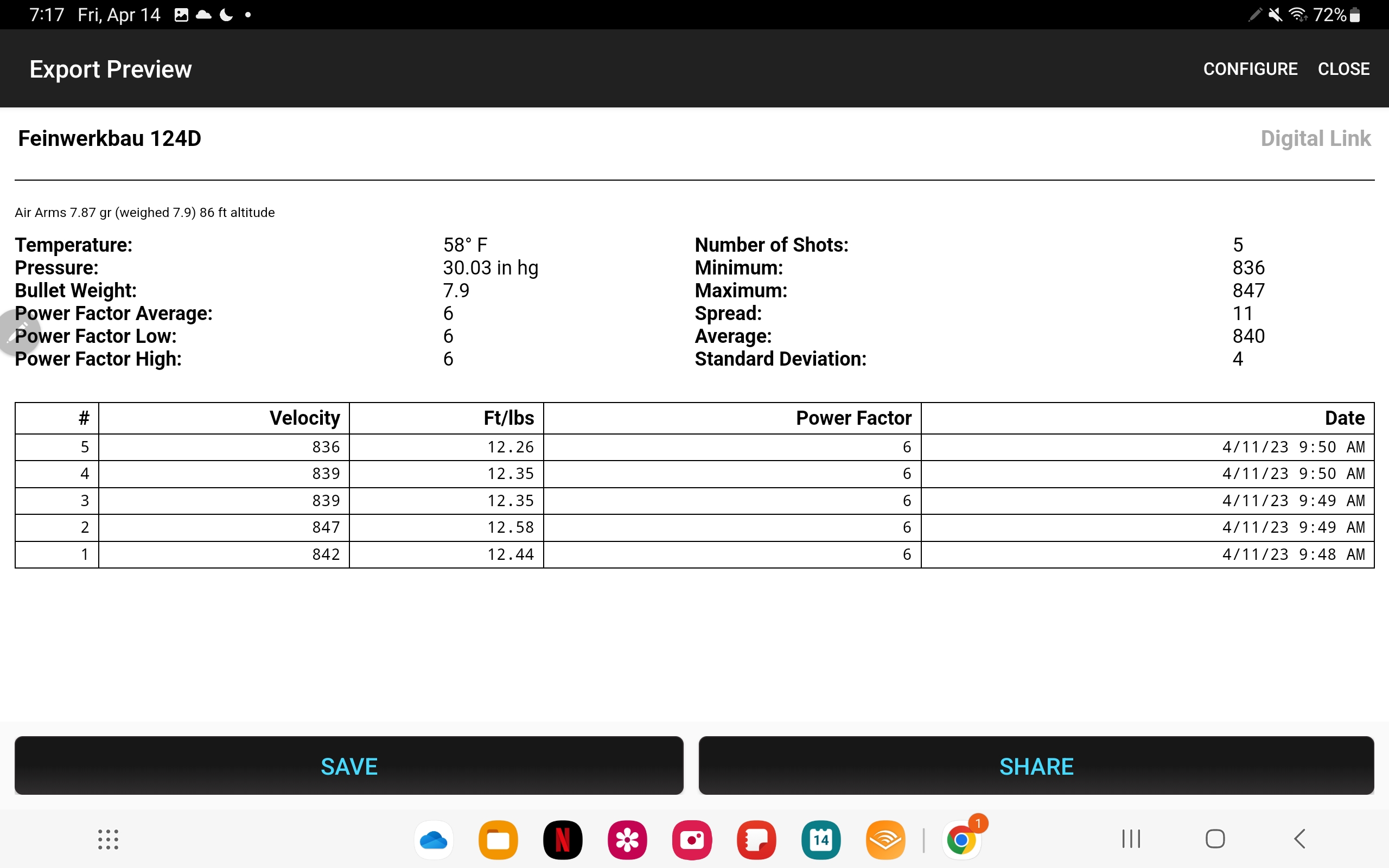

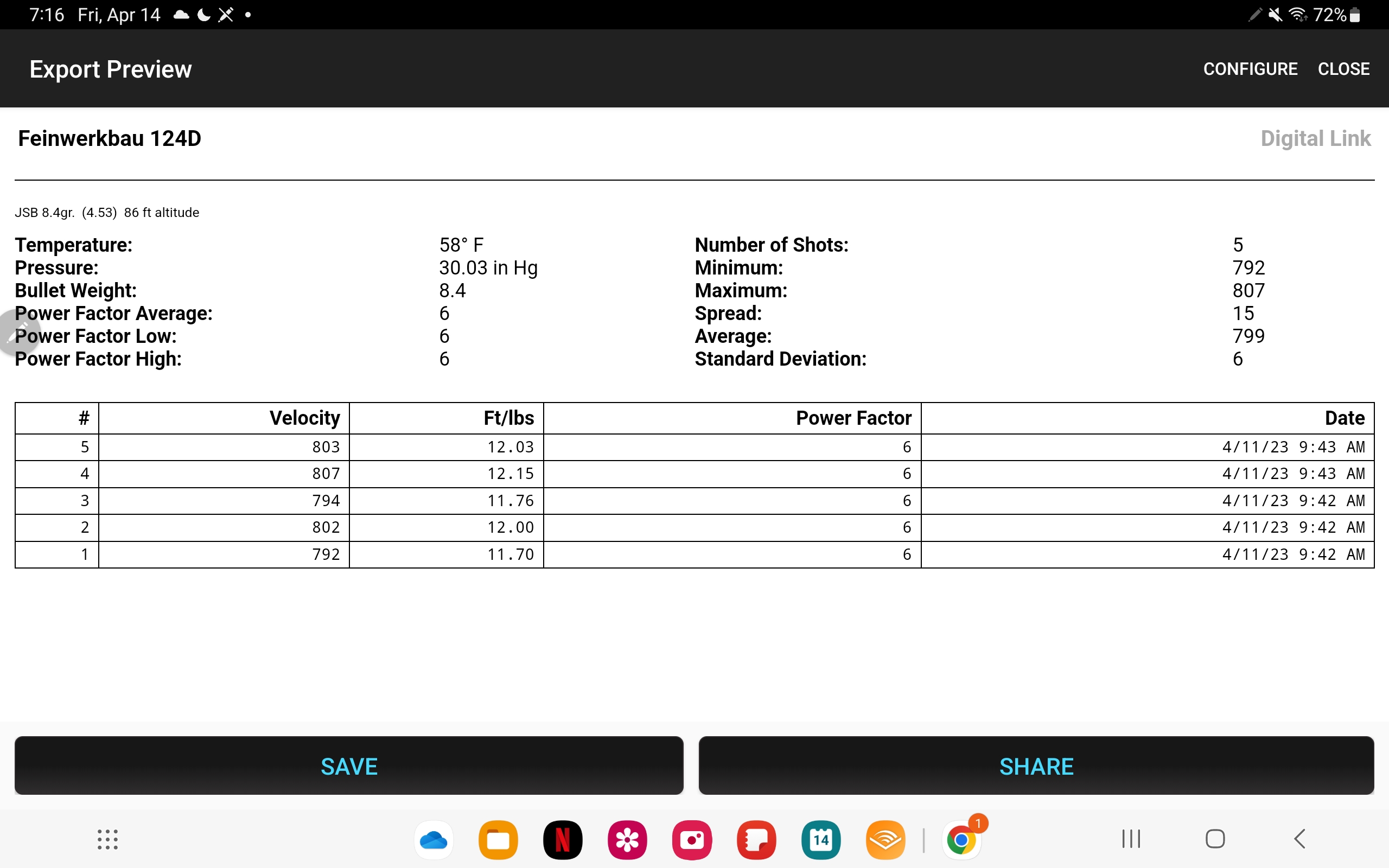

it back together I ran some shots over my chronograph.

the forearm fasteners. I made brass flat washers and used them under the external toothed

star washers but they still slowly came loose. I decided to try a #10 internal toothed lock washer

this time. In both attempts I used Vibra-Tite VC-3 on all three machine screw stock fasteners.

When I had the stock off I noticed the receiver lug screw didn't appear to be bottomed out. I checked

it and it was loose. Probably a good full turn loose ! Has anyone else had this problem? After getting

it back together I ran some shots over my chronograph.