For those who know nothing about how to build something like this but find it extremely interesting (like me) a tutorial:

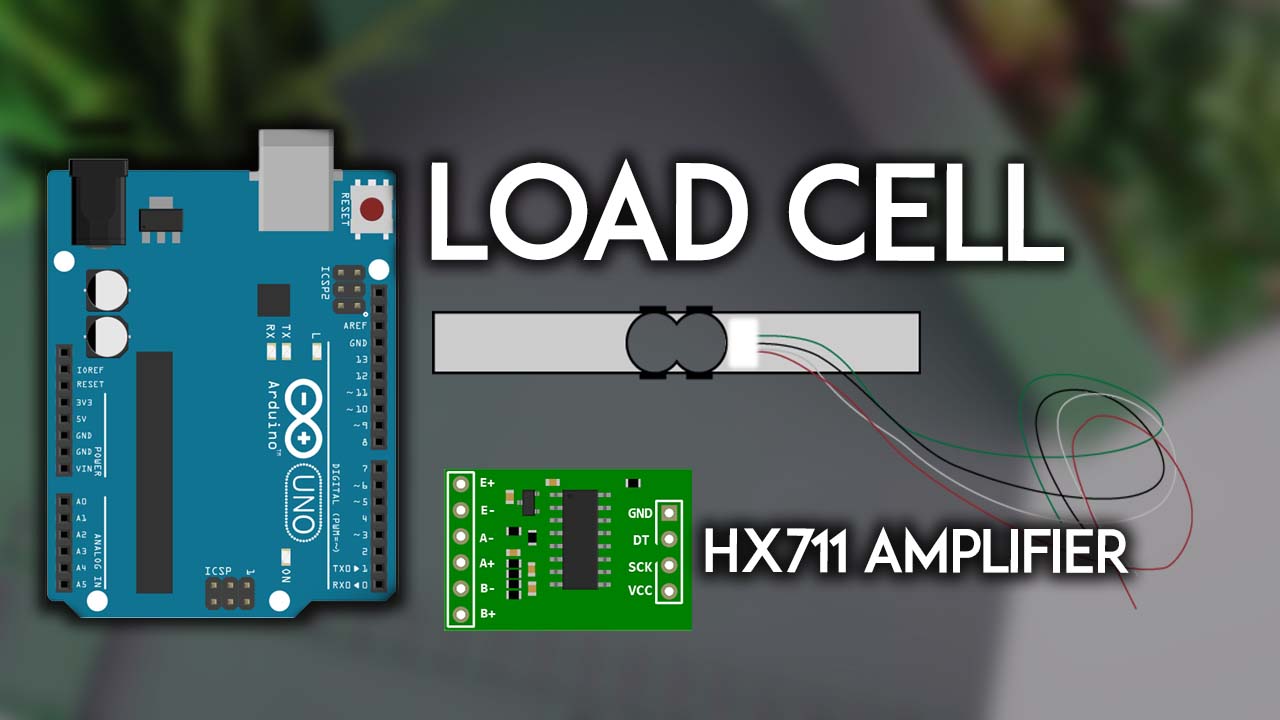

Arduino with Load Cell and HX711 Amplifier (Digital Scale) | Random Nerd Tutorials

Create a digital scale with the Arduino using a load cell and the HX711 amplifier. First, you'll learn how to wire the load cell and the HX711 amplifier to the Arduino to build a scale.randomnerdtutorials.com

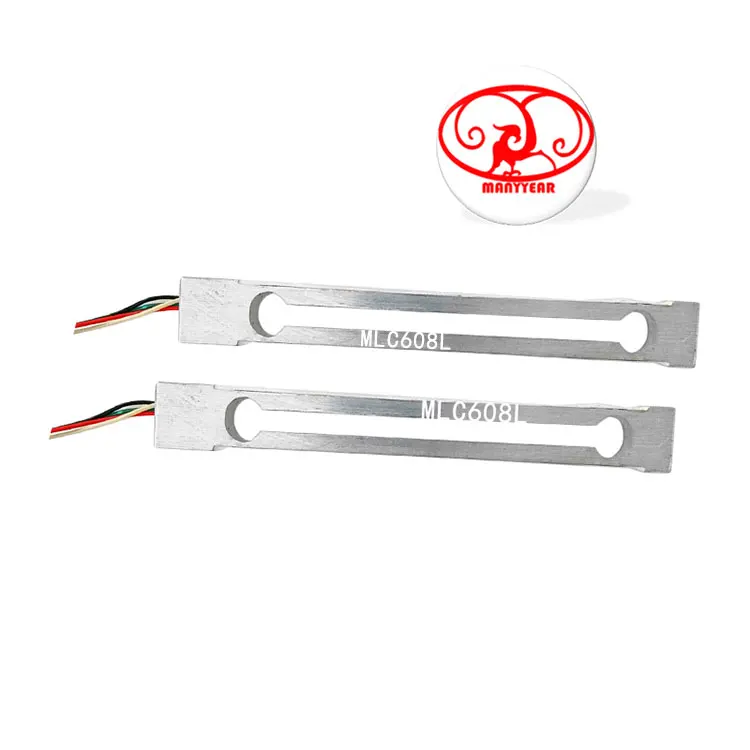

Mlc608l High Accuracy 1mg Accuracy Electronic Balance Scale Micro Weight Sensor Load Cell 20g - Buy Micro Load Cell micro Weight Sensor load Cell 20g jewelry Scale Load Cell jewelry Scale Weight Sensor 1mg Accuracy Load Cell Product on Alibaba.com

Mlc608l High Accuracy 1mg Accuracy Electronic Balance Scale Micro Weight Sensor Load Cell 20g - Buy Micro Load Cell micro Weight Sensor load Cell 20g jewelry Scale Load Cell jewelry Scale Weight Sensor 1mg Accuracy Load Cell Product on Alibaba.com

Upvote 0