I was recording my shooting for review, as I usually do, and had an interesting thing occur. I thought it might be of interest or help to others.

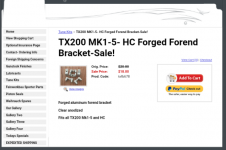

This is a video that was not planned. I was shooting my TX200 MKIII at the indoor range and discovered its’ performance was declining. An inspection found that one of the forend screws had loosened and was about to fall out. I suspect it had been holding on slightly and the natural spring of the wood had kept it functioning. However, as the screw came free from the bracket, but before it fell out, the impact on the consistent accuracy of the rifle became noticeable. After I tightened all the screws, and readjusted the scope, the consistency returned.

This is a stock US version TX200 Mk III, save the addition of a 3mm steel spacer at the front of the top hat. I am shooting weight sorted AA Field Heavy 10.3’s lubricated with Bees Wax Polish. The rifle has a Vortex Diamondback 6-24x50mm scope. I am shooting indoors at 50 feet (16.6 yards) using USA 50/50 targets (2006; 50 foot). I was shooting off an Allen front rest with a Protektor front bag (soft) and Protektor #13 rear bag (semi rigid). The rifle was recently rebuilt with stock parts after about 15K pellets.

This is a video that was not planned. I was shooting my TX200 MKIII at the indoor range and discovered its’ performance was declining. An inspection found that one of the forend screws had loosened and was about to fall out. I suspect it had been holding on slightly and the natural spring of the wood had kept it functioning. However, as the screw came free from the bracket, but before it fell out, the impact on the consistent accuracy of the rifle became noticeable. After I tightened all the screws, and readjusted the scope, the consistency returned.

This is a stock US version TX200 Mk III, save the addition of a 3mm steel spacer at the front of the top hat. I am shooting weight sorted AA Field Heavy 10.3’s lubricated with Bees Wax Polish. The rifle has a Vortex Diamondback 6-24x50mm scope. I am shooting indoors at 50 feet (16.6 yards) using USA 50/50 targets (2006; 50 foot). I was shooting off an Allen front rest with a Protektor front bag (soft) and Protektor #13 rear bag (semi rigid). The rifle was recently rebuilt with stock parts after about 15K pellets.