The answer to this question in short is this- unequivocally, undeniably, resoundingly YES! Yes it does!

So I did an experiment over the weekend. I have a customized .25 AF Condor. It's a slug shooting beast of a gun. But AF rifles aren't known for their complexity in design. They are mechanically simple compared to FX's, or Daystate's, or Edguns, etc..... The utilize an inline valve assembly with a hammer weight propelled by a spring that opens a valve upon impact. They are designed for power, NOT efficiency. Well, there are several manufacturers out there who designed inline regulators for the AF platform. There's PCP Tunes, Altros, and the cheap Chinese manufacturers. The rifles are true PCP's, but they don't have a "bull pup" design. Thus they have an extremely long profile. So in order to add a regulator in the mix, it increases an already long rifle to an even longer rifle. These regulator manufacturers know this, so the plenum space on the regulators is relatively small. I own several of the PCP Tunes regs (which in my opinion have the best tolerance and manufacturing design). I have the V1, the V2, the V3, and the Texan regulator. I don't even own the Texan rifle, but the Reg can be used on smaller caliber Condors and provide extreme power and consistency in velocities. I'm going to throw it on one day....

However, my gun is currently running the V3 regulator. The V3 has 2x's the plenum space as the V1 and the V2. But the plenum space is still limited. They increased the inner volume of the regulator by expanding the circumference slightly. They did not increase it's volume by lengthening it. So the reg goes between the valve assembly and the bottle (as all regs do). And the reg can be set for whatever reg pressure you desire, up to 250 BAR with the ability to have 300 BAR in the bottle. But for this experiment, I'm glad I have the AF Condor platform. It's so mechanically simple that it simplifies the experiment. It's either going to work or it's not.

When you get the PCP Tunes regulator, it has 2 gauges on it. One for the bottle, and one for the plenum pressure. So there's no need to keep the stock gauges on the collar portion of the valve assembly. I just used a 1/8" NPT plug with Megatape to fill that recession. But that location also provides access to the regulated side of the configuration since the pressure gauge is activated from the hole at the bottom that runs perpendicular to the air flow. When components are under extreme pressure, directional air flow is irrelevant. The entire space has equal pressure, and it will release evenly as well.

So..... This was my idea. I was going to make my own power plenum and see if the theory would prove to be right. So I shot over to IMS metals, and purchased a 3/16" thick, round steel end cap. I also purchased a mild steel 1/8 NPT bolt. I cut a round tab out od a 3/16" piece of steel plate and drilled a hole through the middle of it to accommodate the bolt without impeding the threads. The bolt was pushed through the hole, and TIG welded on the inside. I then put the end cap with bolt attached onto the end cap, and TIG welded it shut. It's crude, but VERY strong, and VERY capable of handling the pressure that will be in the plenum.

Here are the pictures:

I realize the hole isn't centered in the middle of the bolt. This is because I improvised with a shotty jig on the drill press instead of doing it by hand. However, it's irrelevant to the functionality of the plenum because that will be screwed into the female threaded collar portion of the valve assembly, which reinforces the walls of the hollow bolt.

Here it is mounted on the regulator. I use a stubby bottle when playing with reg settings to conserve air.

Reg pressure set at 180 BAR

Bottle pressure set at 230 BAR

Mounted on the rifle. Notice the chronograph in the background.

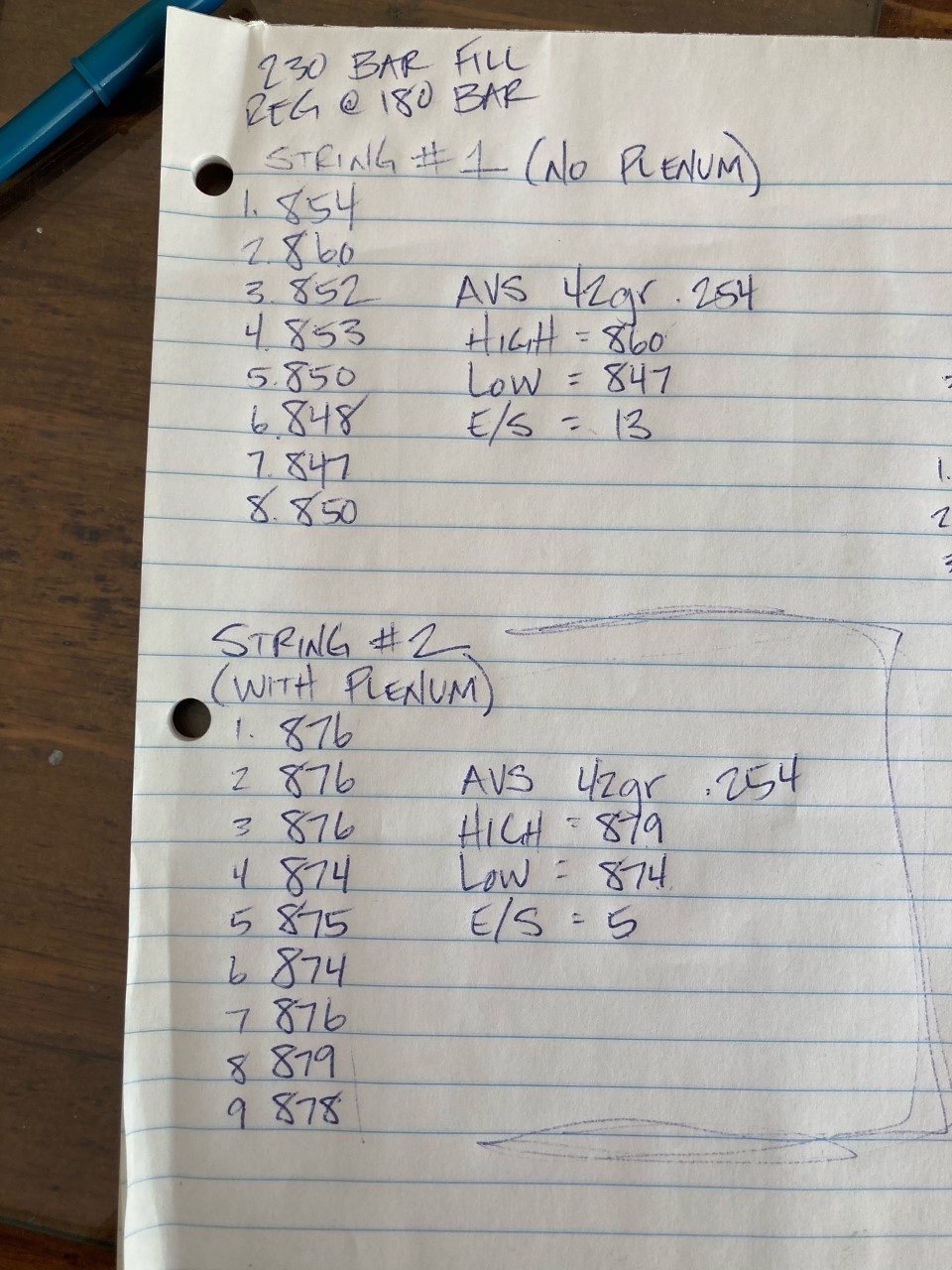

And here are the results of my testing:

Notice that I got an increase of 19fps velocity over the high velocities on each string. I also got a 62% reduction in the extreme spread with the new plenum. Lastly, I got 1 extra shot with the same fill level before the reg dropped off. Again, I use a buddy bottle when I do tests like this. The bottle I normally use has twice the capacity, which exponentially increases the number of shots. So if I could get 9 regulated shots with the buddy bottle, I should get 25 or 26 with the regular carbon fiber bottle. I also usually put 250-260 BAR in the larger bottle.

So if you're ever wondering if a larger plenum (power plenum) really does make a difference, now you have proof. It really does. It creates more power with identical settings. I went from an average velocity of 851.75 fps to 876 fps (+24.25 fps), with a power increase of average 67.68 fpe to 71.58 fpe (+4 fpe).

The V3 reg I normally use with my carbon fiber bottle is set at 210 BAR. I'm pushing the 38gr .254 AVS slugs at 965 fps with those settings. Slugs are particular though. Those slugs may not like being shot faster than that. So I have 2 options with this. Either way, the power plenum will be added to the configuration. I think I'm going to make another one. But I can add the plenum and see how much faster the slugs shoot, and if they still shoot accurate (which will be a feat in and of itself, because they are like laser beams). Or if they are less accurate at the higher velocities, then I will back off the regulator and tune it down to say 200 BAR. Either way, the efficiency and lessening of an extreme spread will follow. So it's a win-win in my book.

So I did an experiment over the weekend. I have a customized .25 AF Condor. It's a slug shooting beast of a gun. But AF rifles aren't known for their complexity in design. They are mechanically simple compared to FX's, or Daystate's, or Edguns, etc..... The utilize an inline valve assembly with a hammer weight propelled by a spring that opens a valve upon impact. They are designed for power, NOT efficiency. Well, there are several manufacturers out there who designed inline regulators for the AF platform. There's PCP Tunes, Altros, and the cheap Chinese manufacturers. The rifles are true PCP's, but they don't have a "bull pup" design. Thus they have an extremely long profile. So in order to add a regulator in the mix, it increases an already long rifle to an even longer rifle. These regulator manufacturers know this, so the plenum space on the regulators is relatively small. I own several of the PCP Tunes regs (which in my opinion have the best tolerance and manufacturing design). I have the V1, the V2, the V3, and the Texan regulator. I don't even own the Texan rifle, but the Reg can be used on smaller caliber Condors and provide extreme power and consistency in velocities. I'm going to throw it on one day....

However, my gun is currently running the V3 regulator. The V3 has 2x's the plenum space as the V1 and the V2. But the plenum space is still limited. They increased the inner volume of the regulator by expanding the circumference slightly. They did not increase it's volume by lengthening it. So the reg goes between the valve assembly and the bottle (as all regs do). And the reg can be set for whatever reg pressure you desire, up to 250 BAR with the ability to have 300 BAR in the bottle. But for this experiment, I'm glad I have the AF Condor platform. It's so mechanically simple that it simplifies the experiment. It's either going to work or it's not.

When you get the PCP Tunes regulator, it has 2 gauges on it. One for the bottle, and one for the plenum pressure. So there's no need to keep the stock gauges on the collar portion of the valve assembly. I just used a 1/8" NPT plug with Megatape to fill that recession. But that location also provides access to the regulated side of the configuration since the pressure gauge is activated from the hole at the bottom that runs perpendicular to the air flow. When components are under extreme pressure, directional air flow is irrelevant. The entire space has equal pressure, and it will release evenly as well.

So..... This was my idea. I was going to make my own power plenum and see if the theory would prove to be right. So I shot over to IMS metals, and purchased a 3/16" thick, round steel end cap. I also purchased a mild steel 1/8 NPT bolt. I cut a round tab out od a 3/16" piece of steel plate and drilled a hole through the middle of it to accommodate the bolt without impeding the threads. The bolt was pushed through the hole, and TIG welded on the inside. I then put the end cap with bolt attached onto the end cap, and TIG welded it shut. It's crude, but VERY strong, and VERY capable of handling the pressure that will be in the plenum.

Here are the pictures:

I realize the hole isn't centered in the middle of the bolt. This is because I improvised with a shotty jig on the drill press instead of doing it by hand. However, it's irrelevant to the functionality of the plenum because that will be screwed into the female threaded collar portion of the valve assembly, which reinforces the walls of the hollow bolt.

Here it is mounted on the regulator. I use a stubby bottle when playing with reg settings to conserve air.

Reg pressure set at 180 BAR

Bottle pressure set at 230 BAR

Mounted on the rifle. Notice the chronograph in the background.

And here are the results of my testing:

Notice that I got an increase of 19fps velocity over the high velocities on each string. I also got a 62% reduction in the extreme spread with the new plenum. Lastly, I got 1 extra shot with the same fill level before the reg dropped off. Again, I use a buddy bottle when I do tests like this. The bottle I normally use has twice the capacity, which exponentially increases the number of shots. So if I could get 9 regulated shots with the buddy bottle, I should get 25 or 26 with the regular carbon fiber bottle. I also usually put 250-260 BAR in the larger bottle.

So if you're ever wondering if a larger plenum (power plenum) really does make a difference, now you have proof. It really does. It creates more power with identical settings. I went from an average velocity of 851.75 fps to 876 fps (+24.25 fps), with a power increase of average 67.68 fpe to 71.58 fpe (+4 fpe).

The V3 reg I normally use with my carbon fiber bottle is set at 210 BAR. I'm pushing the 38gr .254 AVS slugs at 965 fps with those settings. Slugs are particular though. Those slugs may not like being shot faster than that. So I have 2 options with this. Either way, the power plenum will be added to the configuration. I think I'm going to make another one. But I can add the plenum and see how much faster the slugs shoot, and if they still shoot accurate (which will be a feat in and of itself, because they are like laser beams). Or if they are less accurate at the higher velocities, then I will back off the regulator and tune it down to say 200 BAR. Either way, the efficiency and lessening of an extreme spread will follow. So it's a win-win in my book.