While replacing a failed breech seal I stumbled on another issue with my 430L. In essence it is some added drag on the compression tube as it is moved through its travel. The fix won’t dramatically reduce the cocking force, but it might shave a pound or two off of it and should make things just a little bit smoother.

I noticed the problem as I was reassembling the gun. I did a test fit of the Compression Tube (p/n 9 in the diagram below) into the gun. By itself, the compression tube slid smoothly in and out of the gun. But, when the compression tube was attached to the cocking arm (p/n 26) I noticed that it would bind up in certain places. This isn’t very noticeable with the spring in the gun since it happens where the spring is heavily loaded already, but, with the spring out of the gun it became apparent, though it took a while to find. I knew the breech itself moved smoothly throughout the travel range because of the fit check I did with it. But, once it was connected to the cocking arm (p/n 26) it sometimes would bind up around the 70 to 110 degree mark of the cocking arm travel. That binding seemed to add a pound or two to the cocking force needed to move the compression tube. I don’t know how easy it would be to tell in a fully assembled gun, but I do notice that cocking as well as breech closure is now smoother in this area than it was before I took things apart. To describe this I will refer to parts in the 430L parts diagram.

I found two components where there seemed to be some interference at the highest angles or the cocking arm. The cocking arm strut (p/n 26) left some marks in the compression tube mounting lug (p/n 15) on each side of the lug (see the first photo). I filed those areas down a bit, but I still had significant binding after re-assembly. A closer look and I found that I could actually see the compression tube being torqued up towards the cocking arm at certain times ( 70 – 110 degree angle of the cocking stroke) and this caused added friction as the compression tube moved through its travel. The problem lies in the elongated slot and shape of the cocking arm (p/n26) right where the littler chamber tension spring mounting clip (p/n 35) is. The clip (p/n 35) is just a tiny bit too tall and starts putting pressure on the cylinder when the cocking arm (p/n 26) makes contact with it (cocking arm is in that range of 70-110 degrees, and the attaching pin is in the position shown relative to the elongated hole as shown in the 1st photo). A little filing on the clip (indicated in the last photo by the red pen mark) took the pressure off and stopped the binding so the compression tube would slide smoothly throughout the cocking range. If you ever have a 430L apart, it’s worth a look, as it can be fixed simply with a hand file.

Note: You may be able to check it and fix it even if you don’t have a spring compressor and can’t take the gun fully apart. To check it while assembled you could try to cock the gun, then return the cocking arm back toward its locking position at the barrel. Then, bring the cocking arm back towards the cocked position again and see if you can feel any binding. If so, then you can un-cock the gun and then remove the stock from the gun and then the cocking arm from the compression tube and filing part number 35 in the place I did (see last photo). Good luck, and hope this helps.

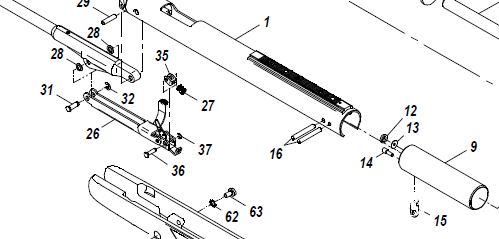

Drawing below shows the 430L part numbers for reference

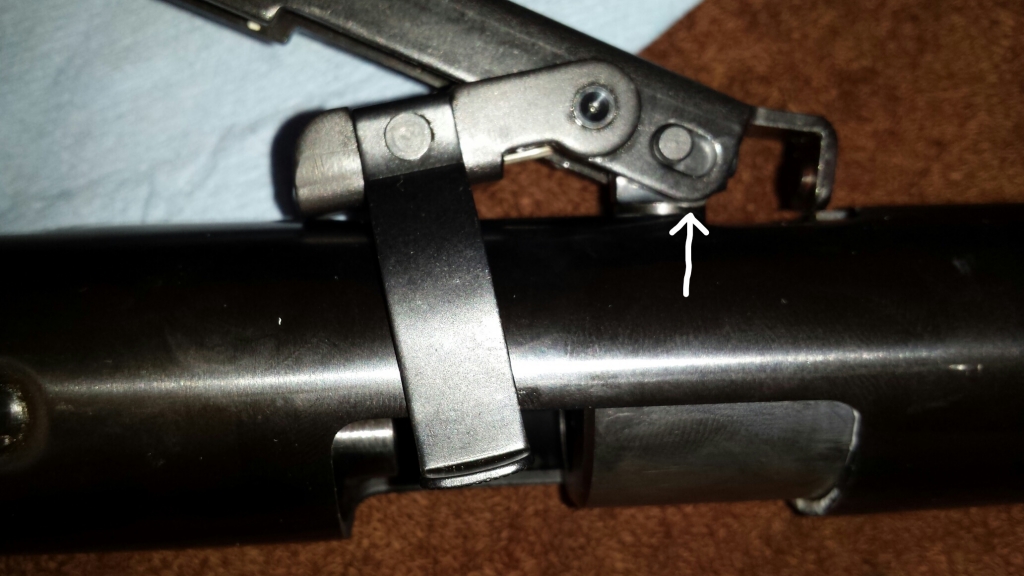

Drawing below shows the cocking arm elongated slot with the compression tube mounting lug (p/n 15) which might need some filing. In the picture you can see some shininess right above the arrow which is the area getting gouged by the cocking arm.

The picture below shows the spring support as removed. File the spring support in the area marked in red. The part that is filed would face the cocking arm at the point shown in green.

I noticed the problem as I was reassembling the gun. I did a test fit of the Compression Tube (p/n 9 in the diagram below) into the gun. By itself, the compression tube slid smoothly in and out of the gun. But, when the compression tube was attached to the cocking arm (p/n 26) I noticed that it would bind up in certain places. This isn’t very noticeable with the spring in the gun since it happens where the spring is heavily loaded already, but, with the spring out of the gun it became apparent, though it took a while to find. I knew the breech itself moved smoothly throughout the travel range because of the fit check I did with it. But, once it was connected to the cocking arm (p/n 26) it sometimes would bind up around the 70 to 110 degree mark of the cocking arm travel. That binding seemed to add a pound or two to the cocking force needed to move the compression tube. I don’t know how easy it would be to tell in a fully assembled gun, but I do notice that cocking as well as breech closure is now smoother in this area than it was before I took things apart. To describe this I will refer to parts in the 430L parts diagram.

I found two components where there seemed to be some interference at the highest angles or the cocking arm. The cocking arm strut (p/n 26) left some marks in the compression tube mounting lug (p/n 15) on each side of the lug (see the first photo). I filed those areas down a bit, but I still had significant binding after re-assembly. A closer look and I found that I could actually see the compression tube being torqued up towards the cocking arm at certain times ( 70 – 110 degree angle of the cocking stroke) and this caused added friction as the compression tube moved through its travel. The problem lies in the elongated slot and shape of the cocking arm (p/n26) right where the littler chamber tension spring mounting clip (p/n 35) is. The clip (p/n 35) is just a tiny bit too tall and starts putting pressure on the cylinder when the cocking arm (p/n 26) makes contact with it (cocking arm is in that range of 70-110 degrees, and the attaching pin is in the position shown relative to the elongated hole as shown in the 1st photo). A little filing on the clip (indicated in the last photo by the red pen mark) took the pressure off and stopped the binding so the compression tube would slide smoothly throughout the cocking range. If you ever have a 430L apart, it’s worth a look, as it can be fixed simply with a hand file.

Note: You may be able to check it and fix it even if you don’t have a spring compressor and can’t take the gun fully apart. To check it while assembled you could try to cock the gun, then return the cocking arm back toward its locking position at the barrel. Then, bring the cocking arm back towards the cocked position again and see if you can feel any binding. If so, then you can un-cock the gun and then remove the stock from the gun and then the cocking arm from the compression tube and filing part number 35 in the place I did (see last photo). Good luck, and hope this helps.

Drawing below shows the 430L part numbers for reference

Drawing below shows the cocking arm elongated slot with the compression tube mounting lug (p/n 15) which might need some filing. In the picture you can see some shininess right above the arrow which is the area getting gouged by the cocking arm.

The picture below shows the spring support as removed. File the spring support in the area marked in red. The part that is filed would face the cocking arm at the point shown in green.