A gentleman on the forum sent me a PM asking for a detailed write up on how to use the Alpha correctly (his message below):

First, Thank You For Your Service! And second, of course I will!!

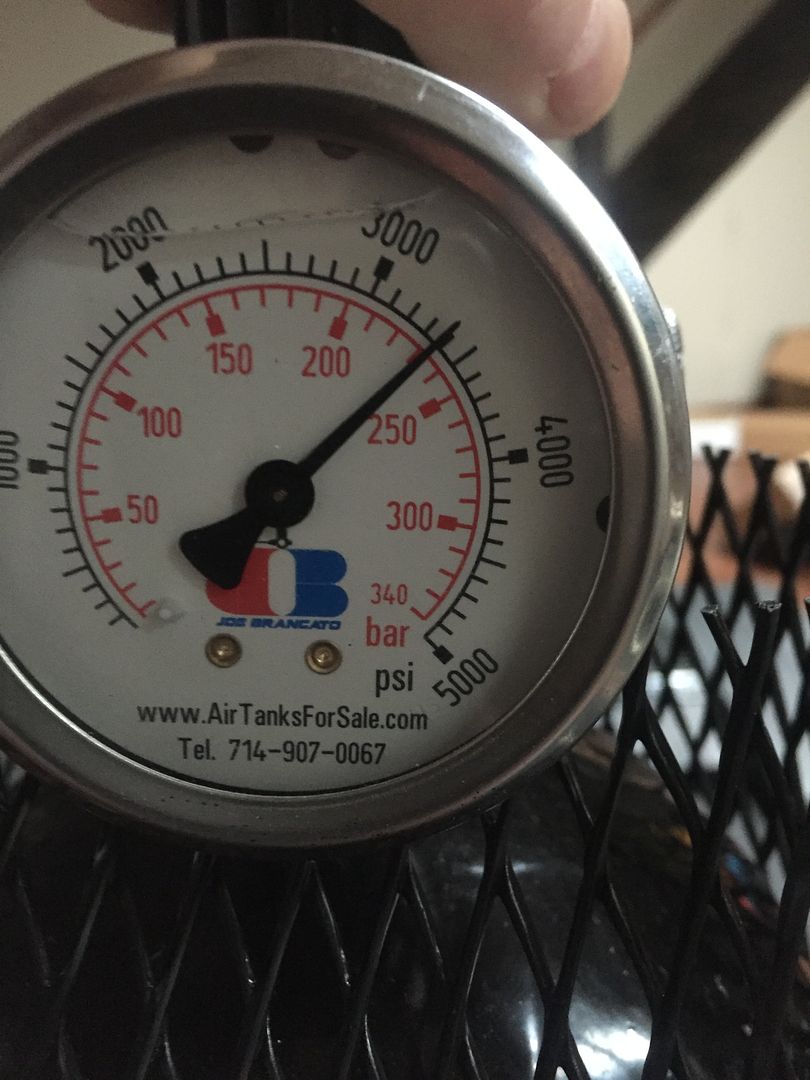

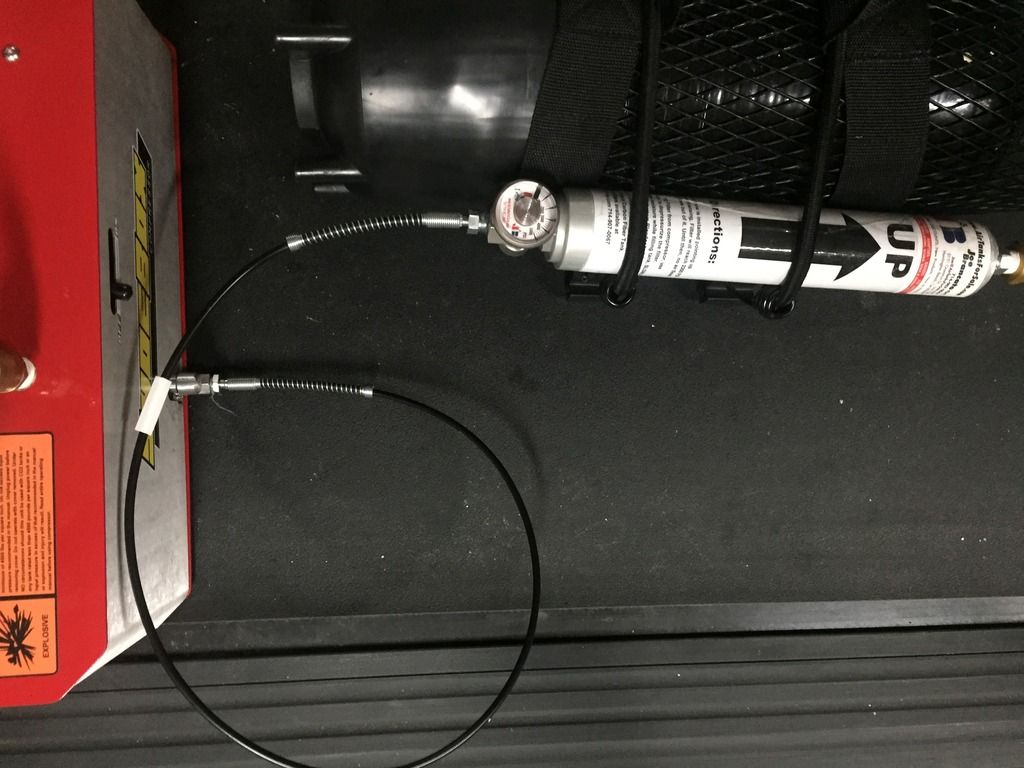

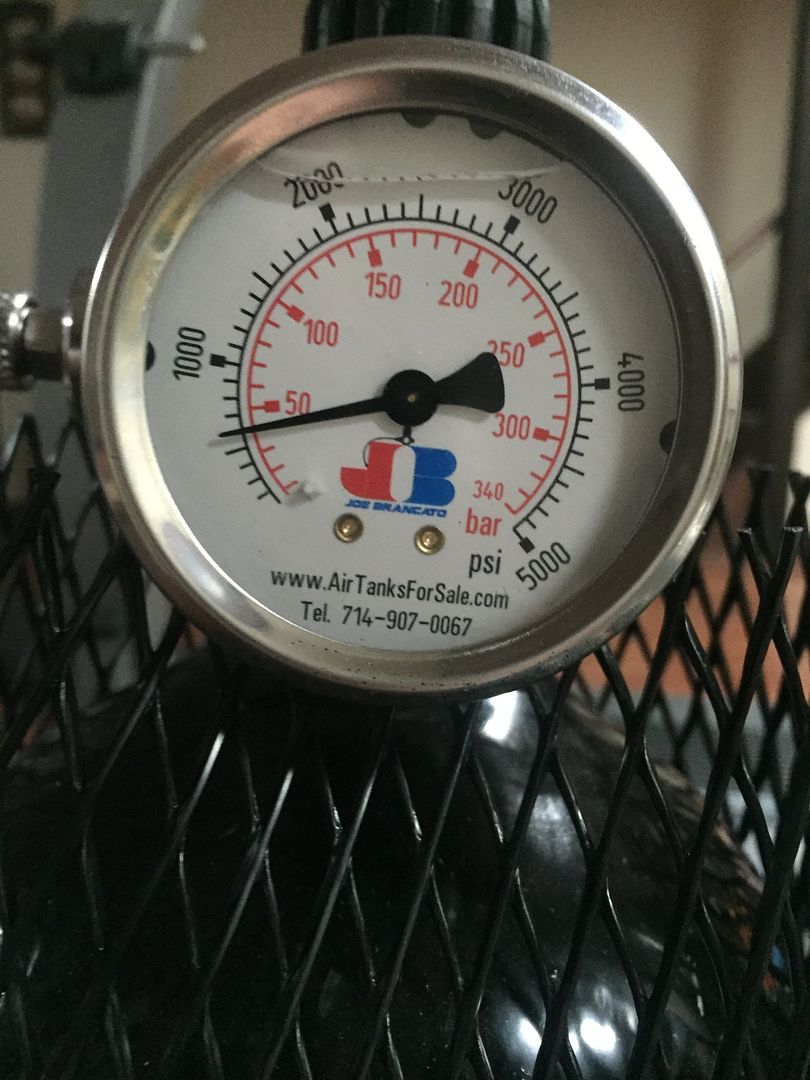

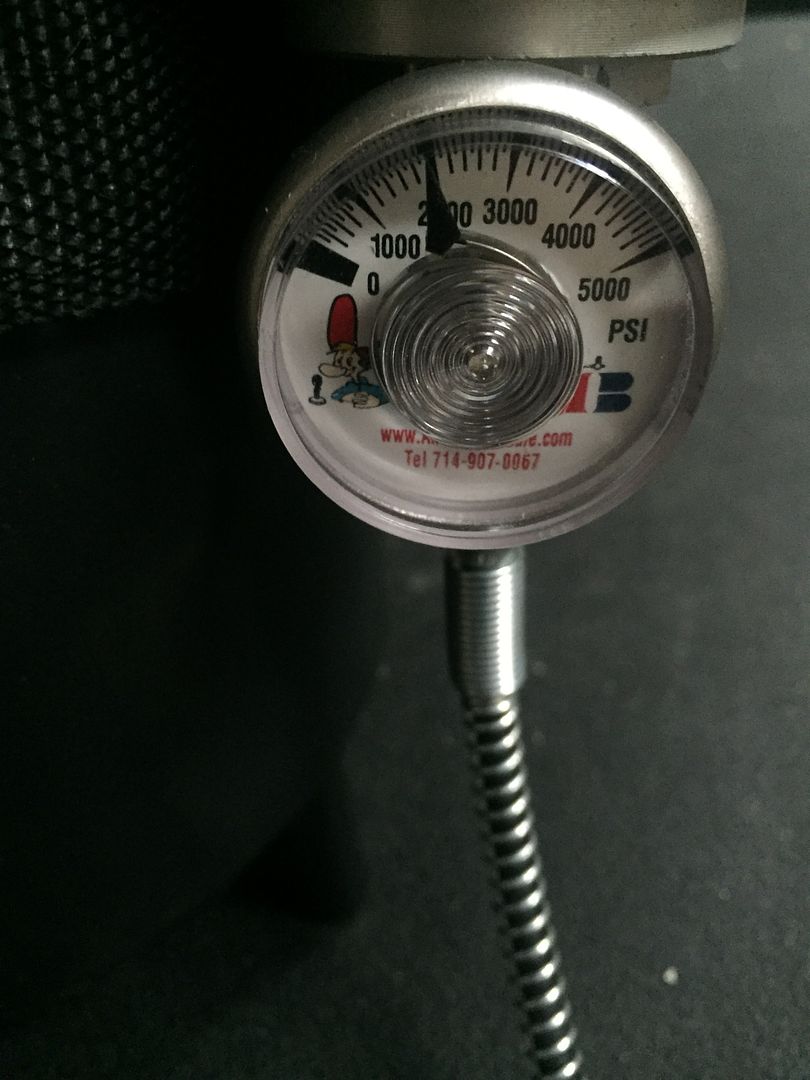

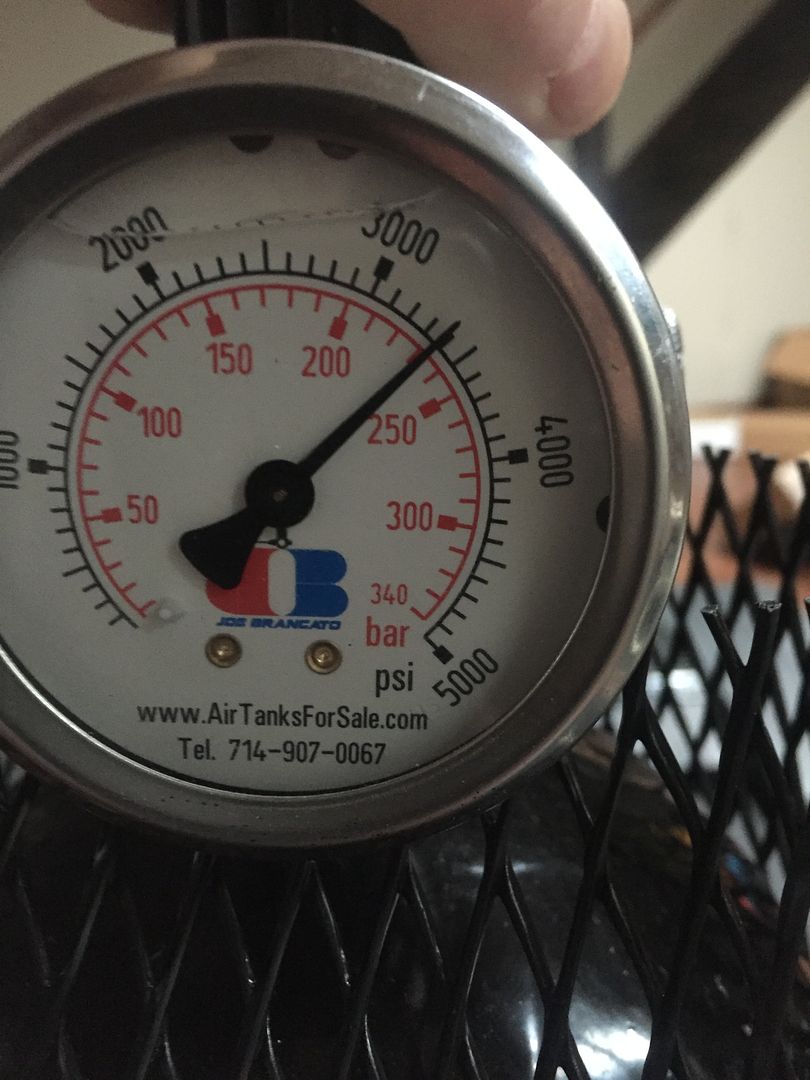

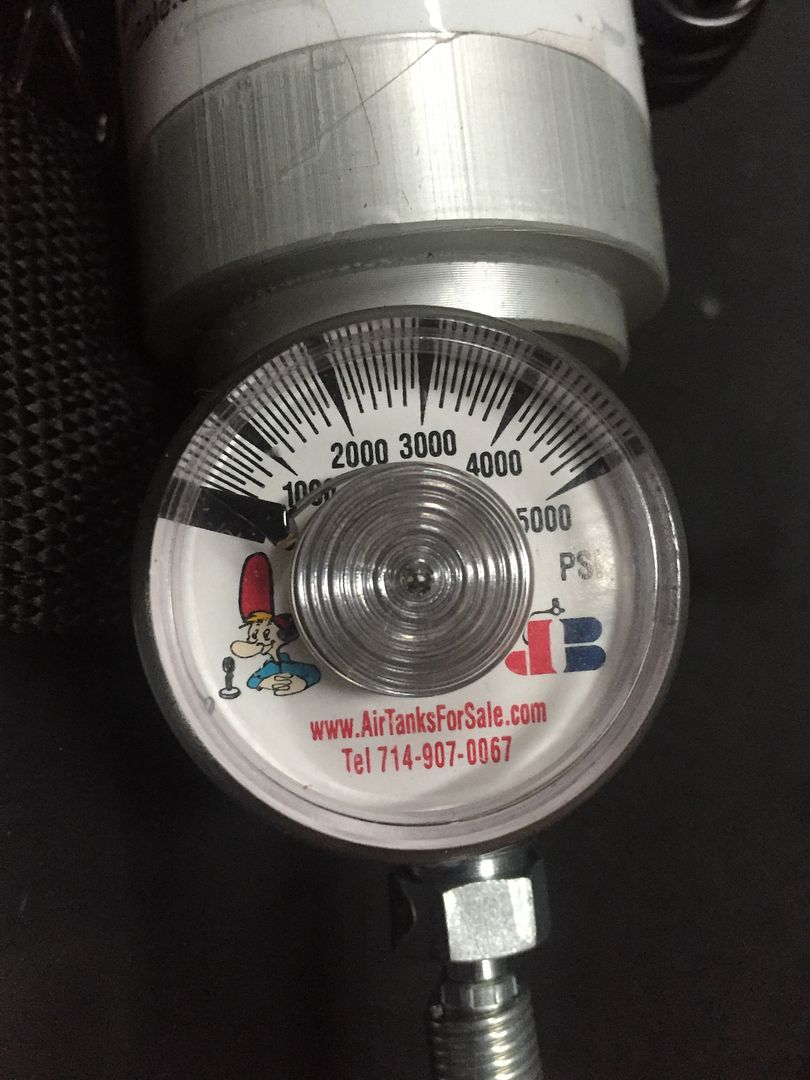

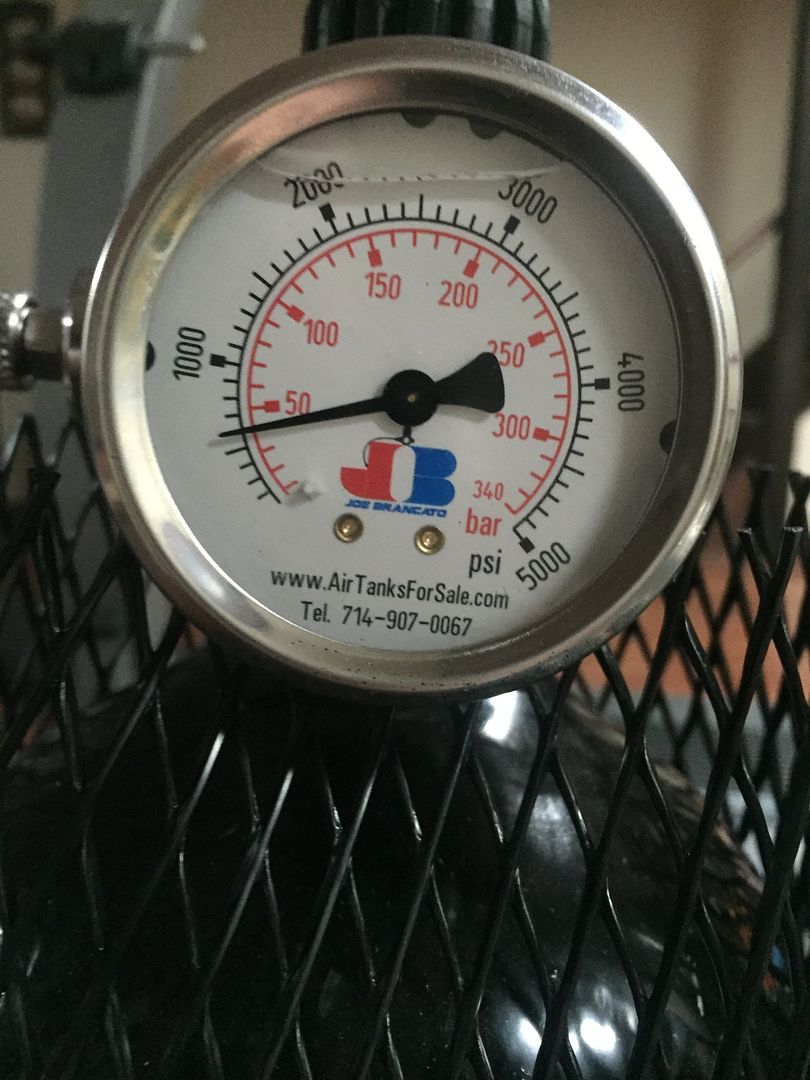

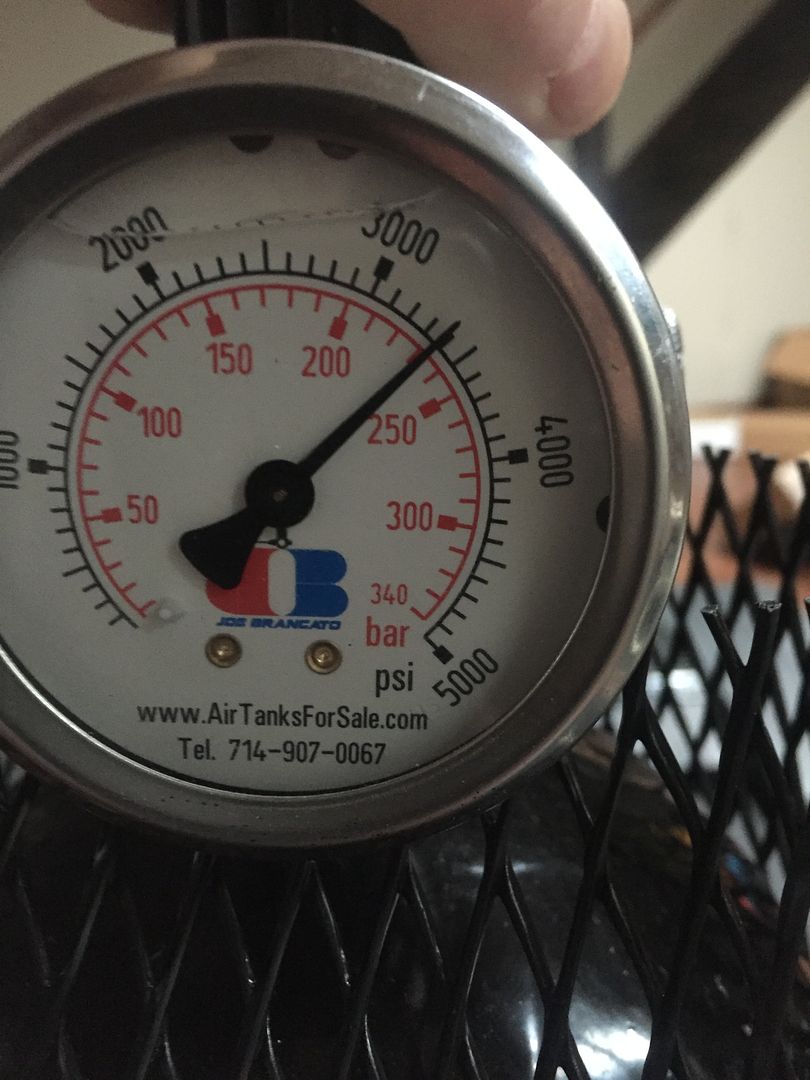

Here is the air pressure left in my tank at the end of this weeks use (I fill up for the weekend). Take note of your remaining air pressure in your tank before you start.

Close the valve on your tank and bleed off the pressure in the line using the tanks bleed valve. Then disconnect the tank from your regulator/gun or whatever it was filling.

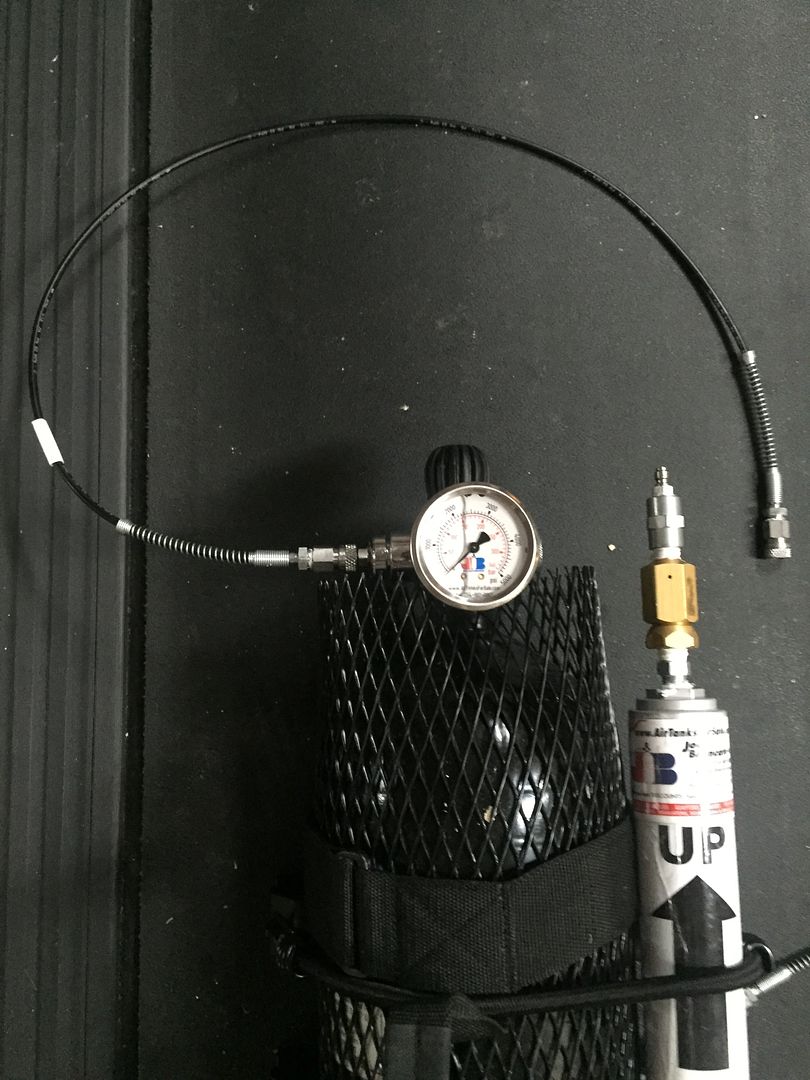

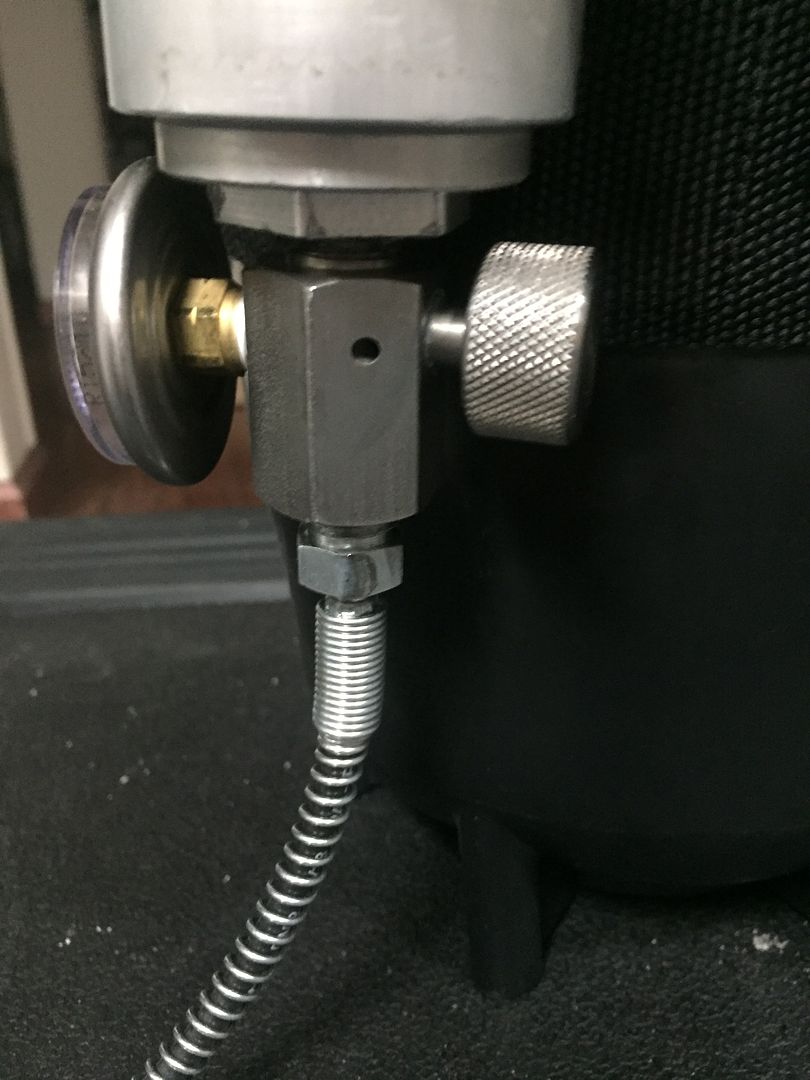

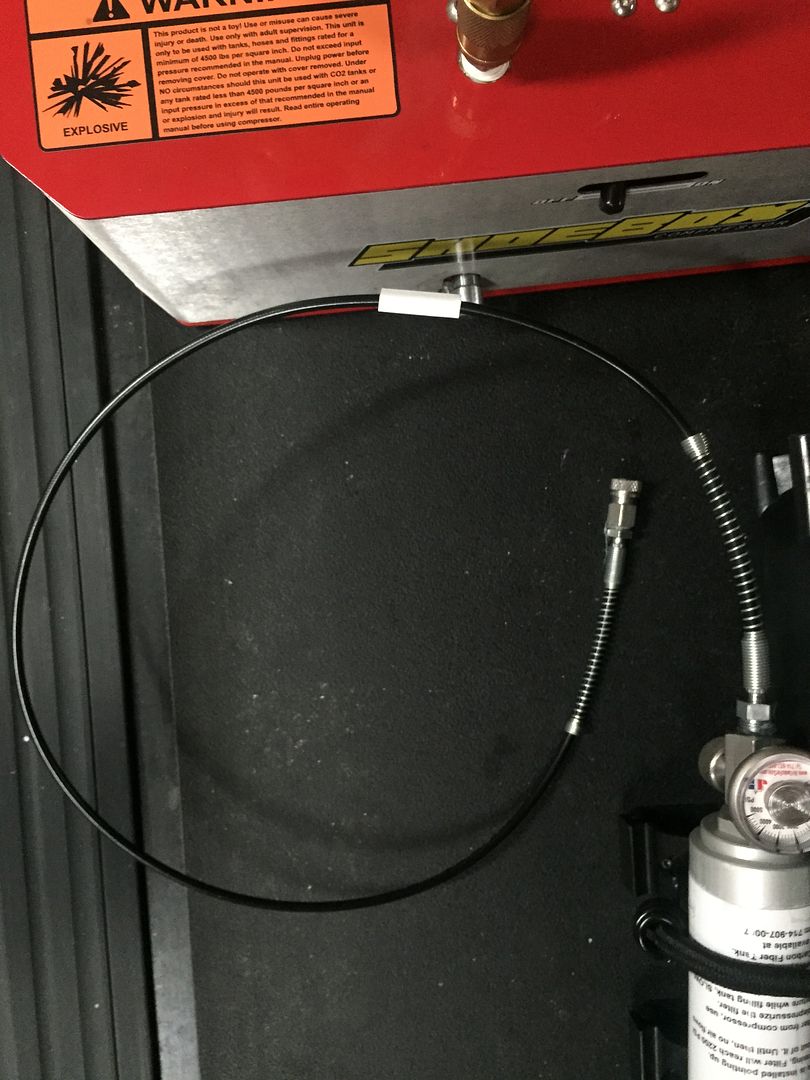

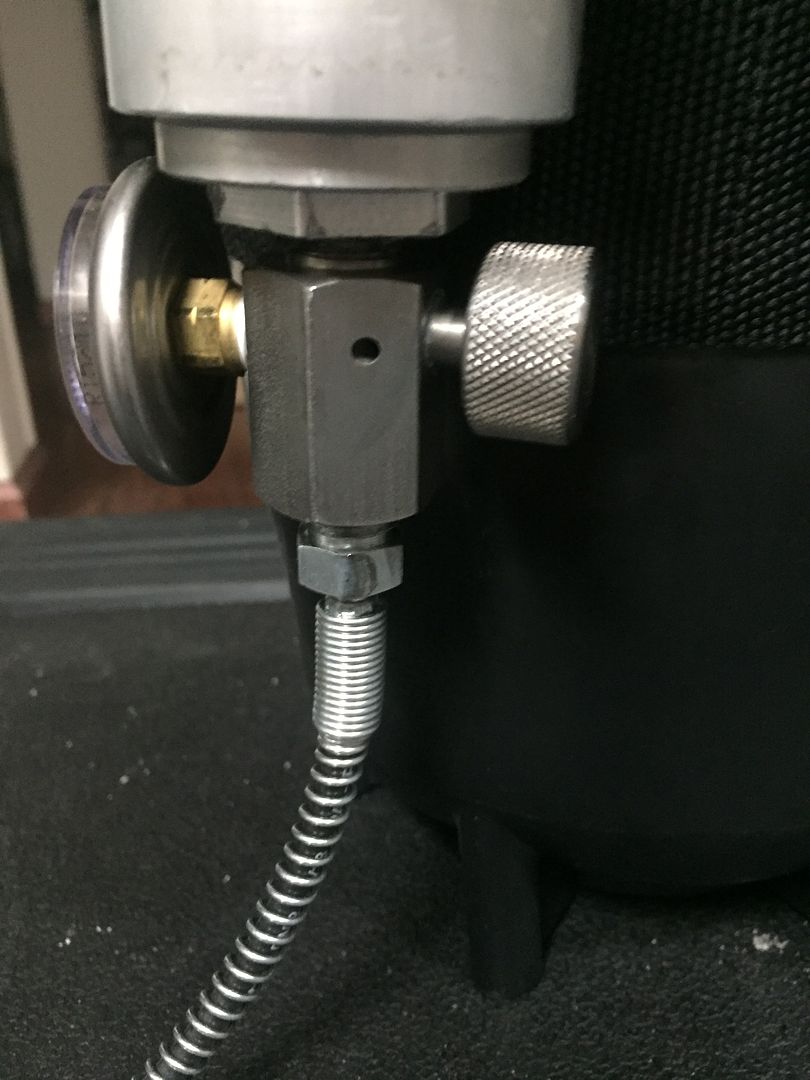

Connect the tank to the top of the Alpha - but leave the tank valve closed. That brass piece you see on top the Alpha with a vent hole is a one way valve. If you have no pressure in the Alpha and you open the main tank valve now you will put a lot of stress on it and can damage it. Yes, I learned this the hard way...thank you Joe B for the repair. You will know it is damaged if air leaks slowly out the vent hole on the one way valve.

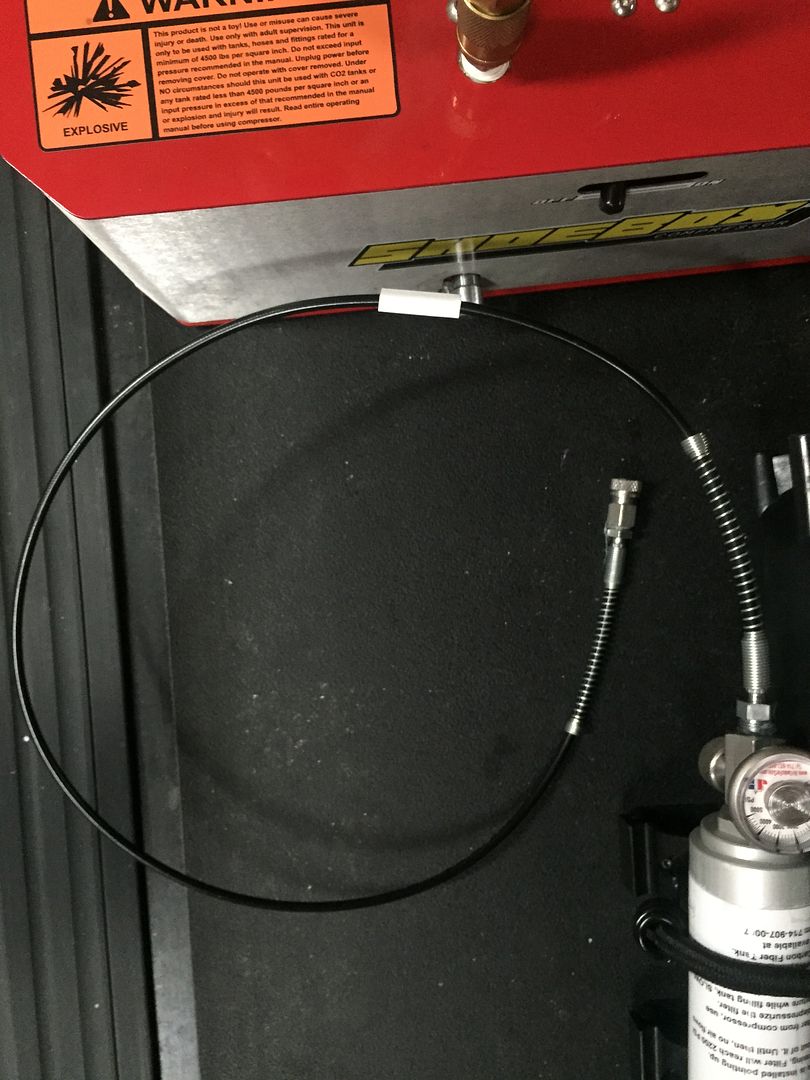

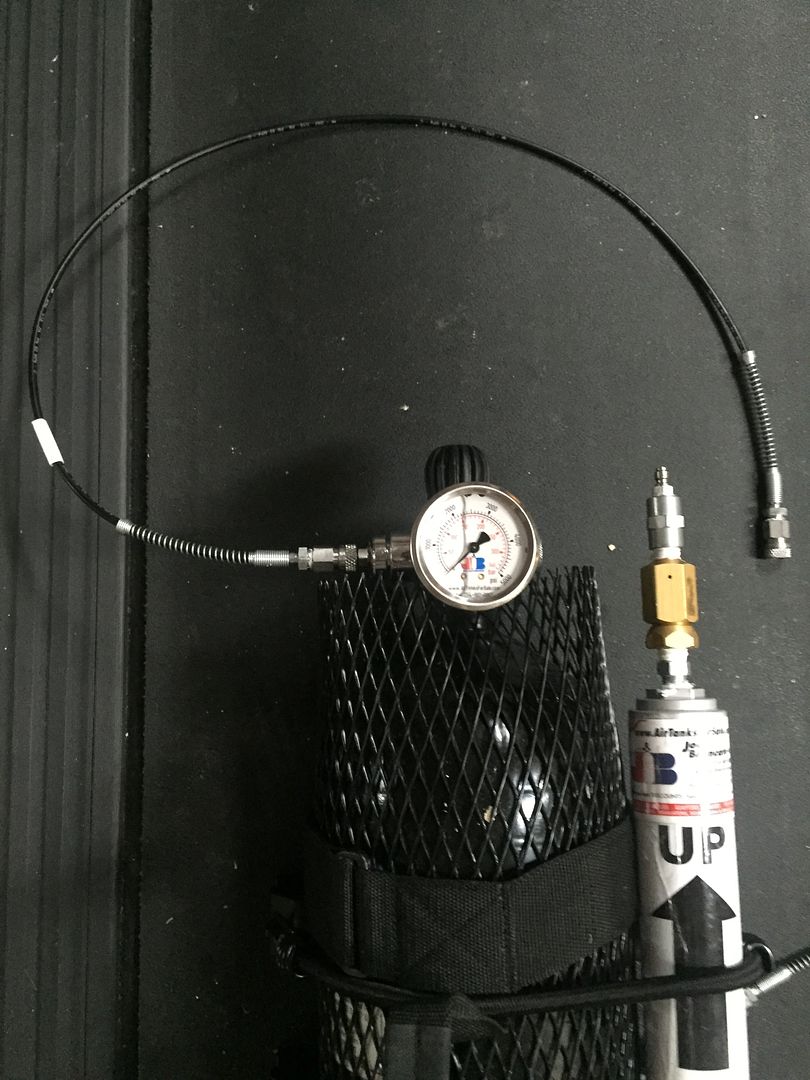

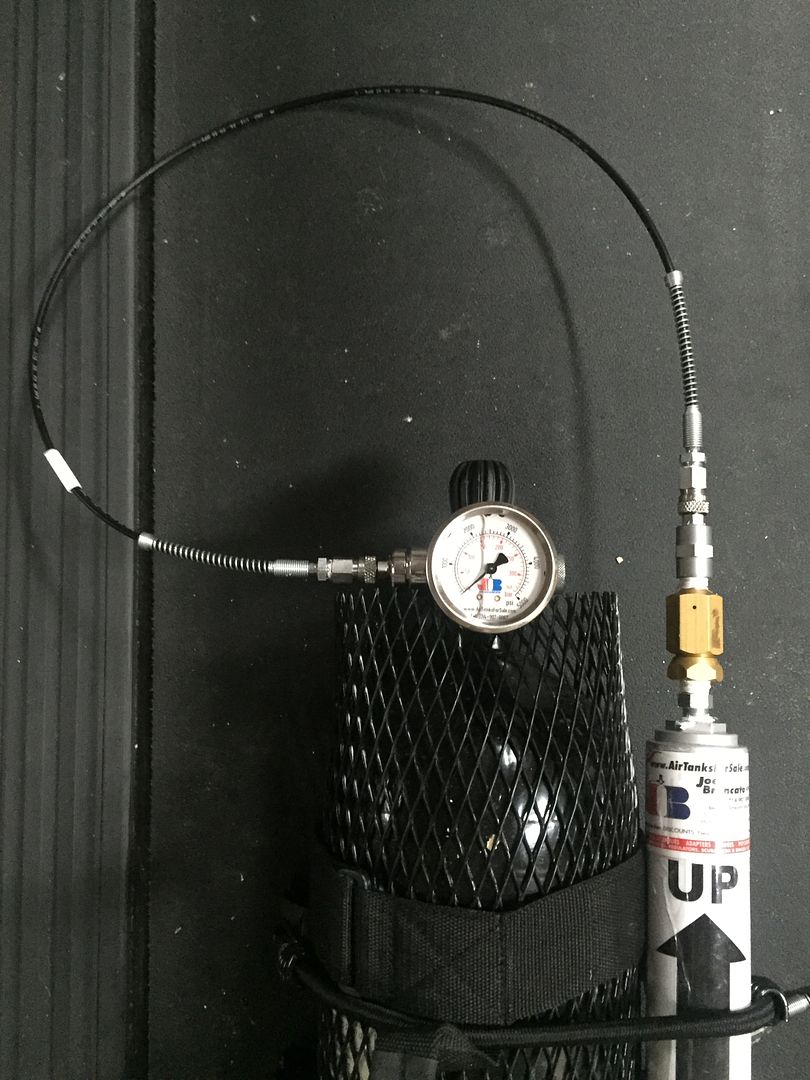

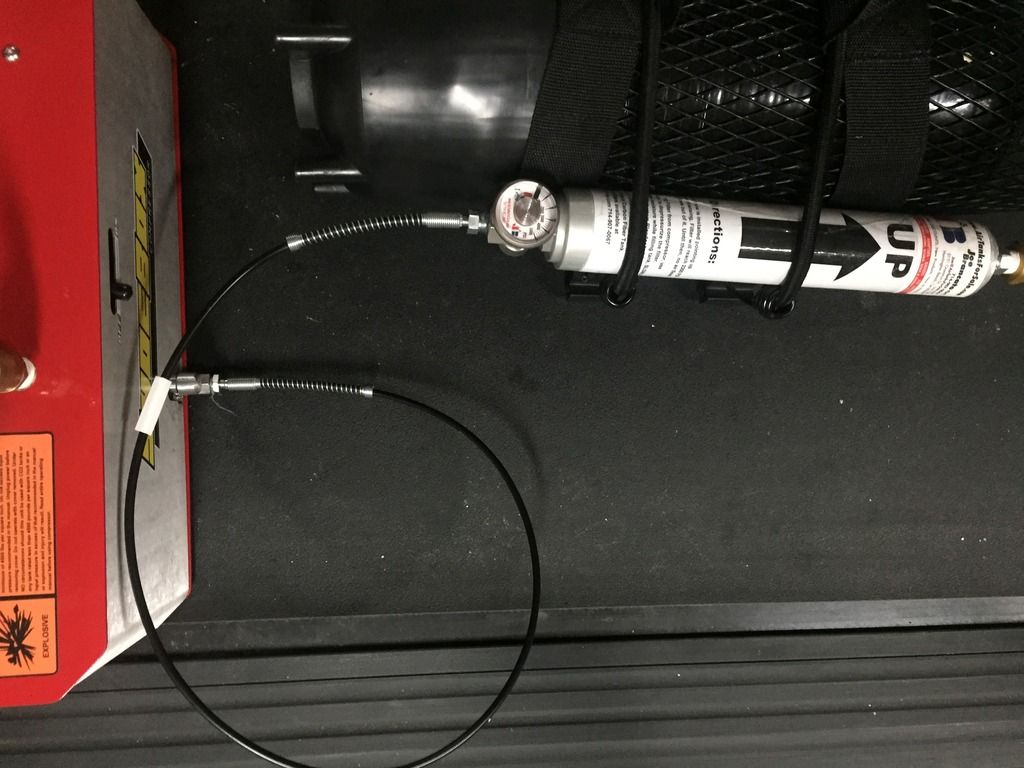

Connect the hose that is attached to the bottom on the alpha to your compressor.

Stand your tank and the Alpha upright to ensure the moisture flows down with gravity

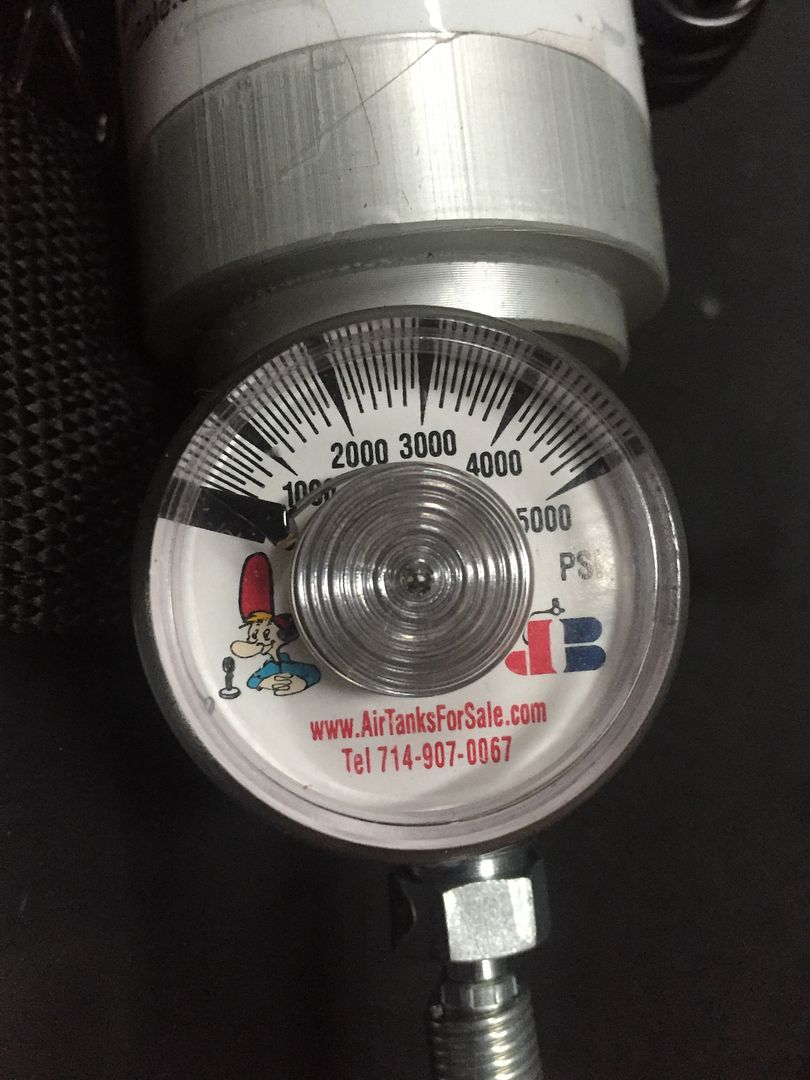

The tank gauge (valve still closed on the tank) and the Alpha's gauge should both be at 0. Start your compressor. From now until many steps later when you open the main tank valve, DO NOT leave the area to do 'something else quick' especially if your compressor does not have a very reliable auto shut off.

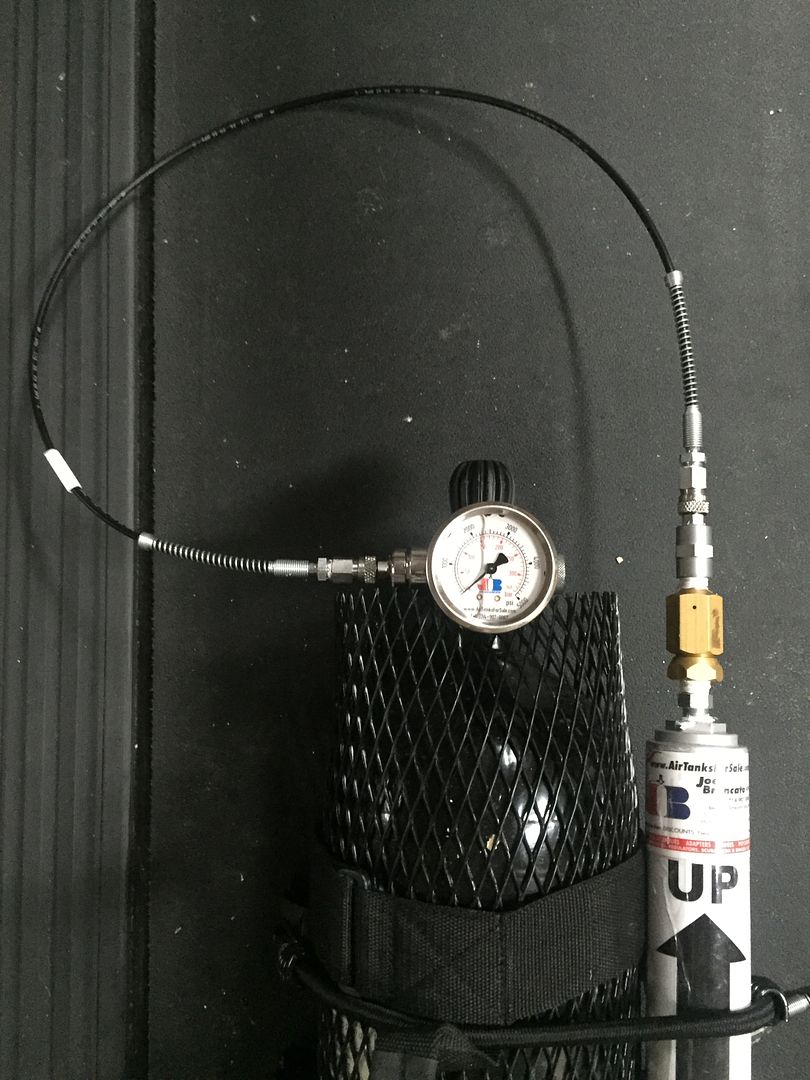

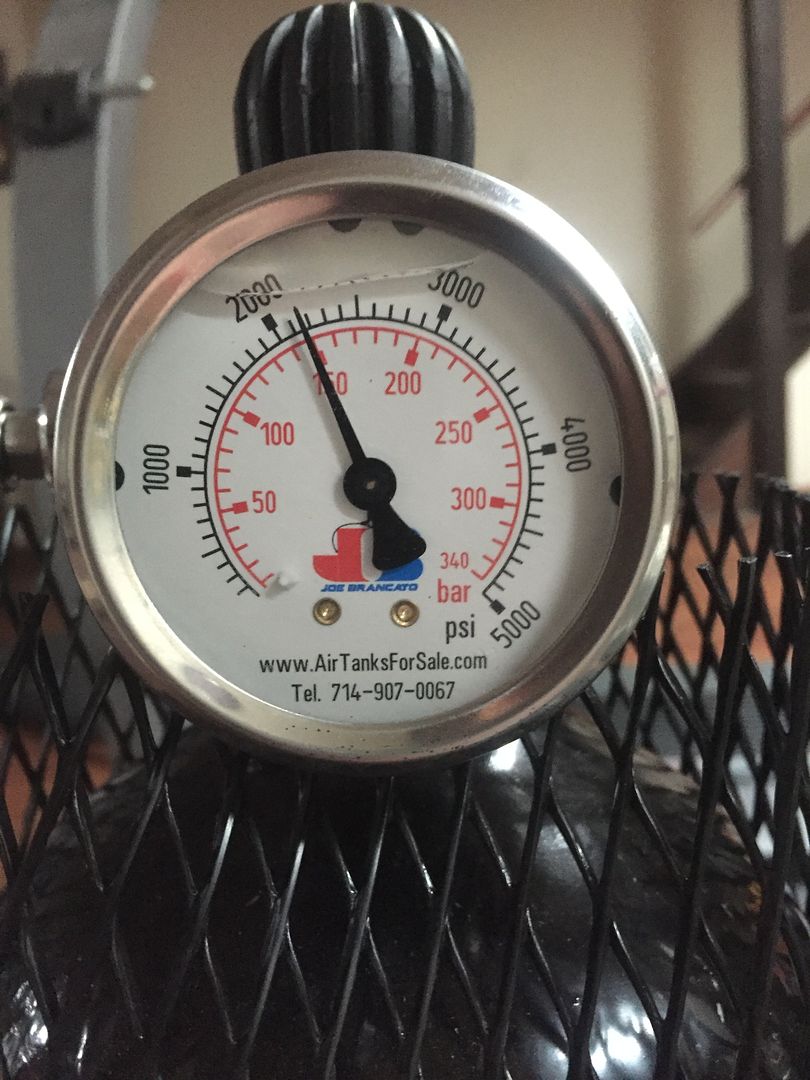

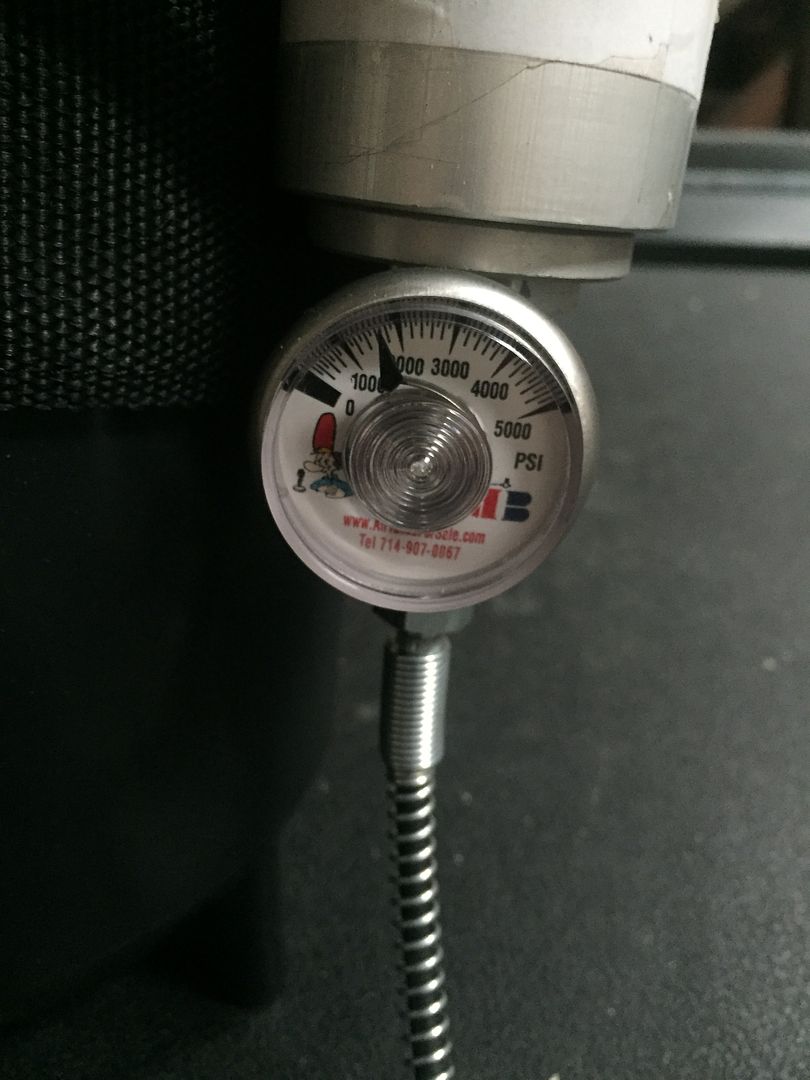

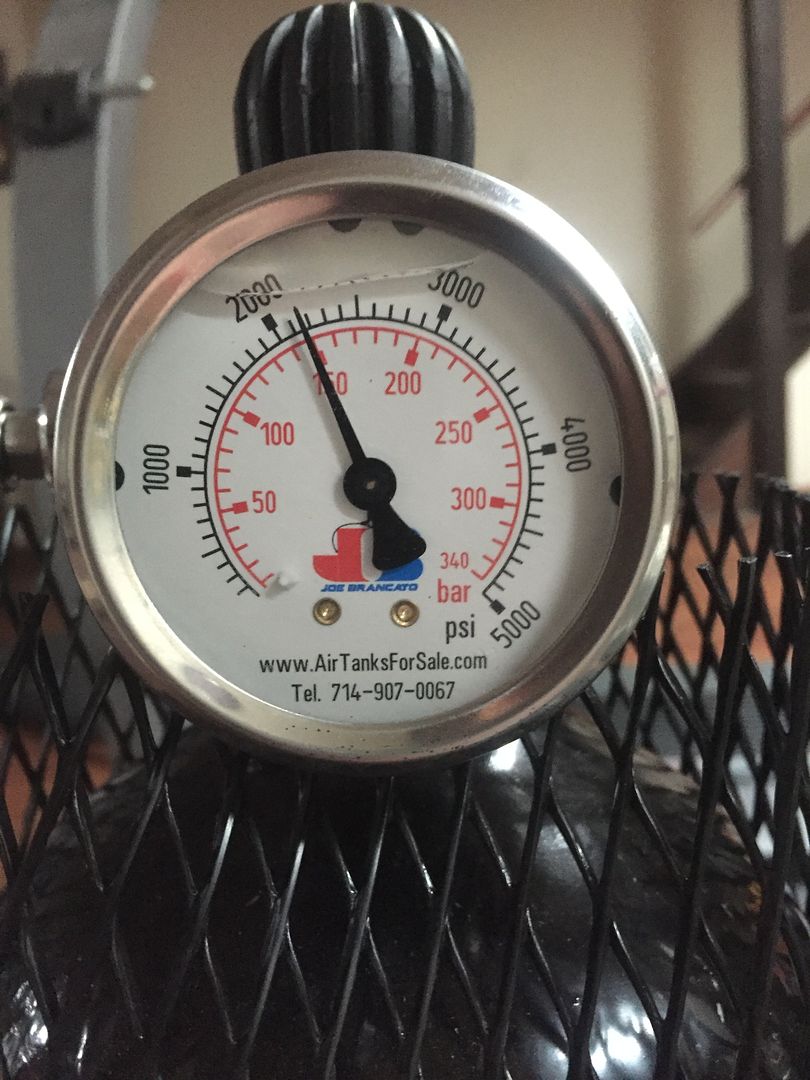

When the gauge on the Alpha gets to about here,

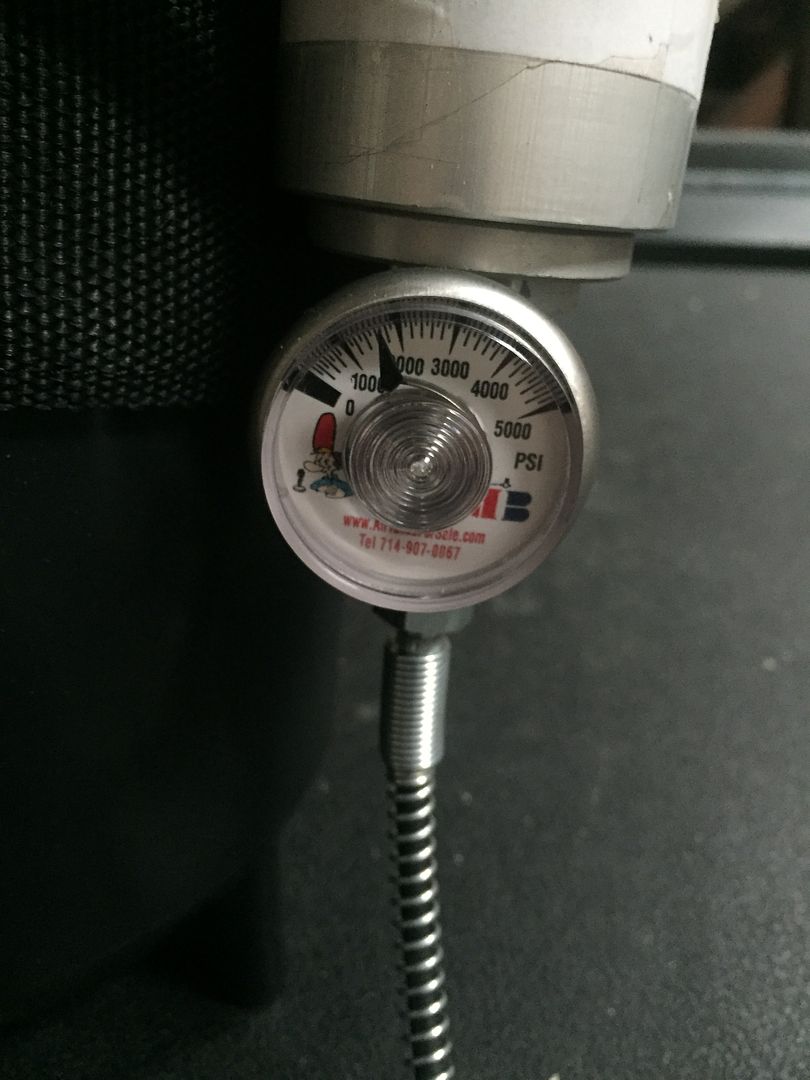

the one way valve on top the Alpha starts to open. You will notice the gauge on the main tank start to rise (a bit faster than when actually pumping into the tank).

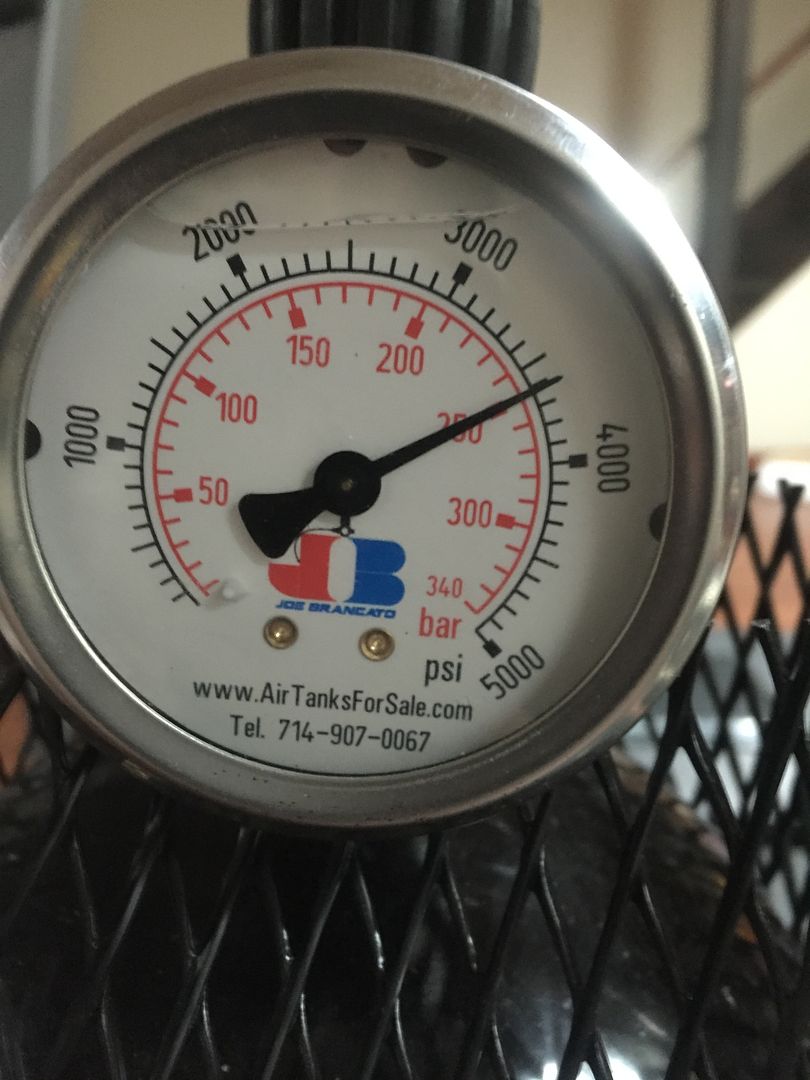

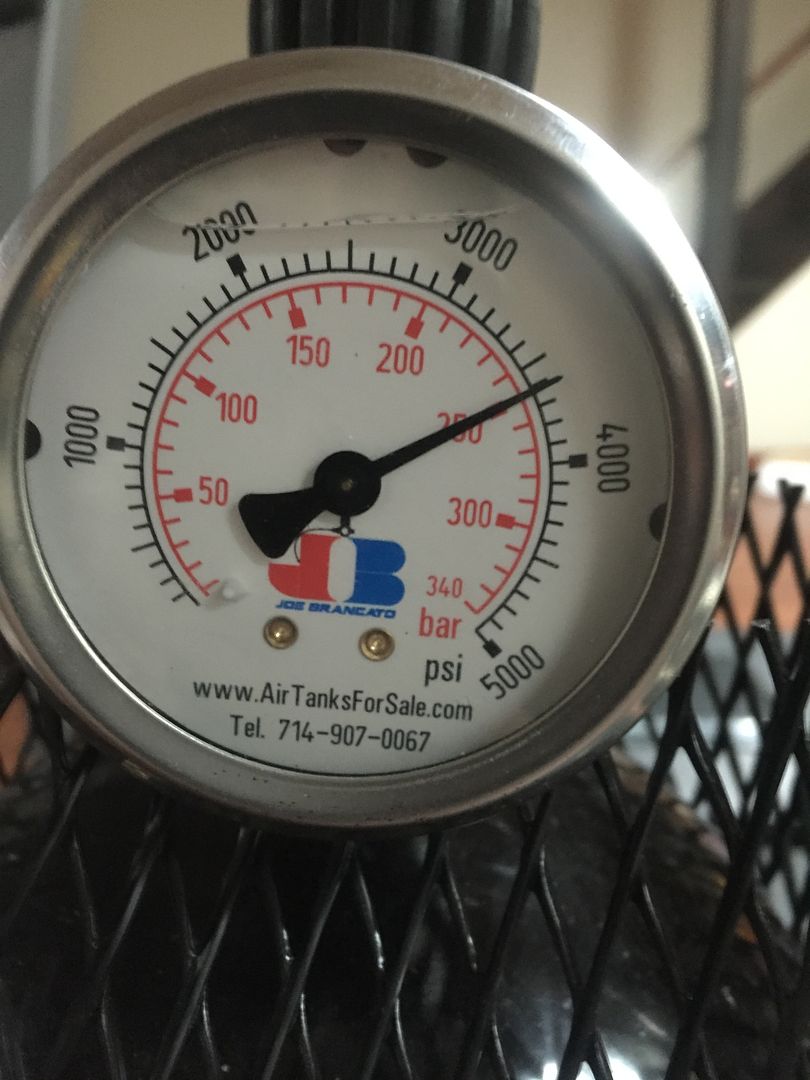

At about 2000 psi on the gauge on the Alpha, the Alphas one way valve should be fully open and the main tanks gauges should match as the Alpha is now freely flowing air.

Your main tanks valve should still be closed at this point and you should see the pressure on the Alphas gauge and the tanks gauge continue to climb together.

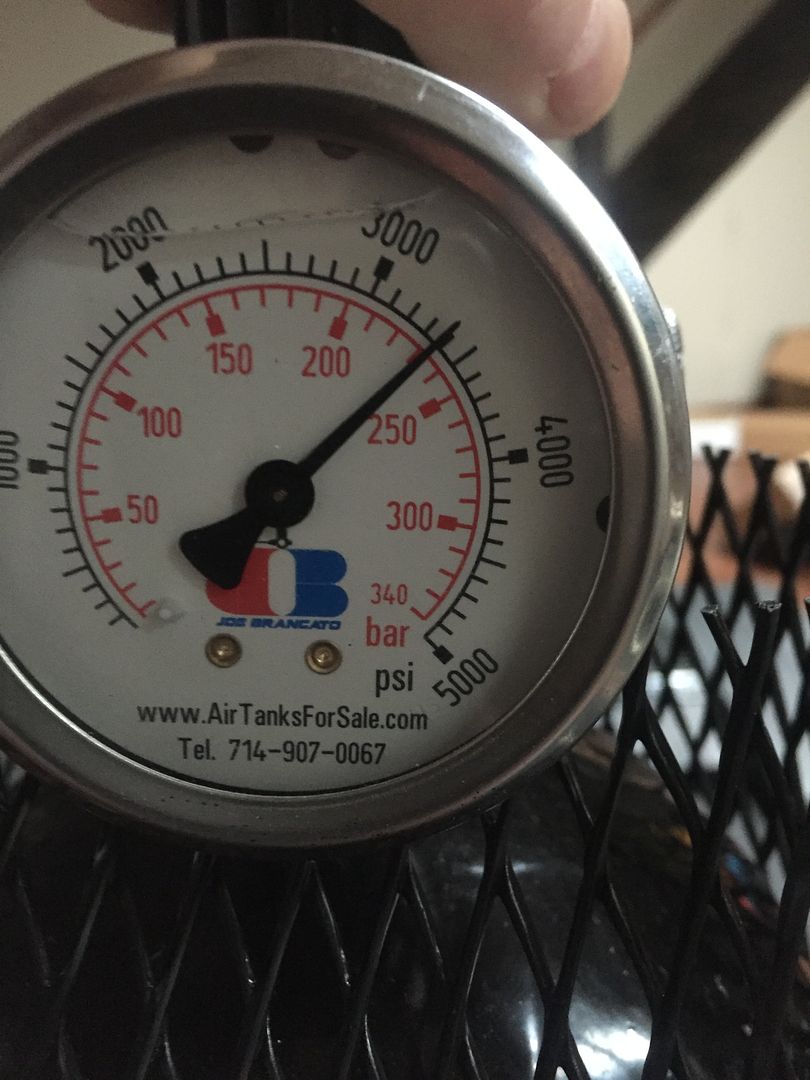

Keep the main tanks valve closed until the main tanks gauge reads 100 to 200 psi past where the main tanks remaining pressure was at when you started

Now than the Alpha has more pressure than your tank, open the valve on the main tank. You will see the main tanks gauge drop back to it's initial pressure.

Let your tank continue to fill until it reaches the desired pressure level. When there, turn off your compressor. Then close the main tanks valve fully. Open the vent valve on the main tank to release the pressure between the main tank and the top of the Alpha. Tank gauge should drop all the way down to zero. There may be a small amount of air that continues to leak from the top of the Alpha down the line to your main tanks vent. That is fine, and you will probably see 1800 or so PSI left on the Alpha's gauge. That is the one way valve (brass piece with the small vent hole) working as designed.

At the bottom of the Alpha there is a small knurled knob and a small vent hole. Depending on where you are, you might want to have a towel or something in font of the vent hole to catch the moisture and lubricants from your compressor that made it into the Alpha during pumping. If you want to try and catch these in a glass to see what's getting caught, open the knurled knob at the bottom of the Alpha slowly. You will probably get a teaspoon or so. If you'd rather just blast that stuff out of the Alpha, open the knurled knob quickly. Be ready for a loud whoosh.

And there is your detailed write up! If there is anything that is unclear, let me know and I'll update it.

I'll take a +1 on the accuracy tab if this met your needs.

- Another member of AirGun Nation contacted me and asked me how to use the Alpha – the blind leading the blind!!! If you have the time would you go through the procedure on how you use the Alpha Air Filter with your compressor? My friend (another Viet Vet)and I both own the Omega Super Air Compressor. If you could be as detailed as possible it would be very much appreciated.

First, Thank You For Your Service! And second, of course I will!!

Here is the air pressure left in my tank at the end of this weeks use (I fill up for the weekend). Take note of your remaining air pressure in your tank before you start.

Close the valve on your tank and bleed off the pressure in the line using the tanks bleed valve. Then disconnect the tank from your regulator/gun or whatever it was filling.

Connect the tank to the top of the Alpha - but leave the tank valve closed. That brass piece you see on top the Alpha with a vent hole is a one way valve. If you have no pressure in the Alpha and you open the main tank valve now you will put a lot of stress on it and can damage it. Yes, I learned this the hard way...thank you Joe B for the repair. You will know it is damaged if air leaks slowly out the vent hole on the one way valve.

Connect the hose that is attached to the bottom on the alpha to your compressor.

Stand your tank and the Alpha upright to ensure the moisture flows down with gravity

The tank gauge (valve still closed on the tank) and the Alpha's gauge should both be at 0. Start your compressor. From now until many steps later when you open the main tank valve, DO NOT leave the area to do 'something else quick' especially if your compressor does not have a very reliable auto shut off.

When the gauge on the Alpha gets to about here,

the one way valve on top the Alpha starts to open. You will notice the gauge on the main tank start to rise (a bit faster than when actually pumping into the tank).

At about 2000 psi on the gauge on the Alpha, the Alphas one way valve should be fully open and the main tanks gauges should match as the Alpha is now freely flowing air.

Your main tanks valve should still be closed at this point and you should see the pressure on the Alphas gauge and the tanks gauge continue to climb together.

Keep the main tanks valve closed until the main tanks gauge reads 100 to 200 psi past where the main tanks remaining pressure was at when you started

Now than the Alpha has more pressure than your tank, open the valve on the main tank. You will see the main tanks gauge drop back to it's initial pressure.

Let your tank continue to fill until it reaches the desired pressure level. When there, turn off your compressor. Then close the main tanks valve fully. Open the vent valve on the main tank to release the pressure between the main tank and the top of the Alpha. Tank gauge should drop all the way down to zero. There may be a small amount of air that continues to leak from the top of the Alpha down the line to your main tanks vent. That is fine, and you will probably see 1800 or so PSI left on the Alpha's gauge. That is the one way valve (brass piece with the small vent hole) working as designed.

At the bottom of the Alpha there is a small knurled knob and a small vent hole. Depending on where you are, you might want to have a towel or something in font of the vent hole to catch the moisture and lubricants from your compressor that made it into the Alpha during pumping. If you want to try and catch these in a glass to see what's getting caught, open the knurled knob at the bottom of the Alpha slowly. You will probably get a teaspoon or so. If you'd rather just blast that stuff out of the Alpha, open the knurled knob quickly. Be ready for a loud whoosh.

And there is your detailed write up! If there is anything that is unclear, let me know and I'll update it.

I'll take a +1 on the accuracy tab if this met your needs.