So at the risk of sounding like a total idiot, do i need a valve of some kind to avoid damaging anything/to be able to (safely)connect and disconnect the gun considering it still has almost 200 bar in the bottle? in case this would vary from one gun to another due to some having a built in one way valve that stops the reservoir from emptying once the fill probe is connected, the gun in question is an fx impact m3 and the compressor is a cheap vevor portable with a coalescing “filter” on the output. i ask because i know i read something somewhere about how starting the compressor against the leftover pressure of the rifle is a good way to instantly destroy it and the fx user manual(which seems excellent in some respects and absolutely terrible in others) makes it sound like letting the system pressure drop below the regulators is a serious no-no… so do i just use the compressor bleed valve having it running before connecting the gun then close it and let the pressure left in the gun go back into the tower(seems counter productive to me)? or should i get one of those things to fill the bottle separately? i think thatd be a good bit cheaper than the $40 tuxing(whose products im very hesitant to trust with 4500 psi after seeing that one review of the exploded gold filter) valve/filter thing i found on amazon that i dont even know for sure if its a flow valve or a blowoff… sorry if thats confusing, i cant figure out what to type into google to get anything helpful back lol , thanks a bunch 4 any help!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

connecting a pressurized gun to a compressor

- Thread starter yungun

- Start date

btw this question stemmed from my getting lucky in finding that the quick disconnect fittings lock under pressure trying to use a deadhead to a. test my new compressor, filter, and fittings/hoses and b. pre-pressurize the tower… lol i coulda shot my eye out without even touchin a triggering

Upvote 0

When you start your compressor to fill your gun, it will start at zero and build pressure until it exceeds the bottle pressure in the gun. It will then overcome the check valve and continue filling the gun until you shut it off. Then simply bleed your fill line, and your done. Not sure if that answers your question. The compressor sees no pressure by simply attaching to the gun, it builds its own pressure. You shouldn’t partially fill, shut down the compressor, and restart without bleeding the fill line.

Upvote 0

THANK YOU!!! i dunno if you know how much of a struggle its been to tryn find that information(all the “how tos” i checked out on youtube were very useless at least for bein that youtube videos save are like my go to whenever im not getting something or dont wanna cause any more issues tryna fix somethin on a car. pretty much all just the obvious, and a few people giving advice on how to ruin your gear lol)… but yeah thank you my friend, money saver at the very least and quite possibly a life saver…+1 to your accuracy, only because +5 wasnt an option!

Upvote 0

The bottle can be full but the hose is empty, so the compressor is not starting against pressure.

Upvote 0

The key words to take from Scotty’s advice is CHECK VALVE. All pcp guns have a check valve system wether an air tube platform or bottle fed.

but when connecting a compressor to a fill tank your hand turning the tanks valve is the check valve, so do not open the tanks valve until pressure from tank and compressor has equalized

but when connecting a compressor to a fill tank your hand turning the tanks valve is the check valve, so do not open the tanks valve until pressure from tank and compressor has equalized

Upvote 0

Augie (Bigragu) is correct about filling TANKS (not gun bottle) UNLESS you put a one way check valve on fill adapter that allows you to open tank before connecting the compressor fill hose. It also keeps one from losing any pressure in tank while bleeding moisture during fill process.

Upvote 0

np as long as the hose is bled before starting it and your not exceeding the rating on the presser ..

Upvote 0

I have a one way valve on my second moisture filter so my YH does not see the bottle pressure until it pumps up to that level and a bit beyond so it overcomes the one way valve. A gun fill works the same way. But you always should start the compressor with the bleed valve open. I reopen it briefly about every 5 minutes to let moisture out. No bottle air is lost when bleeding off moisture due to the one way.

Upvote 0

This is all great advice - thanks! I just purchased a compressor/tank combo so that I no longer have to hand pump. Now I need to look into that check valve for the tank. Any suggestions?

Upvote 0

hey

would that filter with a valve be the $40 tuxing on amazon by any chance? or one of joe b’s *cough*, well im gonna refrain from criticizing the mans business model since im sure i dont fully understand all the factors behind his(very high seeming) prices? i ask because im curious if the tuxing filter with valve is a check or a blowoff valve… heres a link.

TUXING PCP compressor Release filter oil-water filter Cotton filter 1set/lot

https://www.amazon.com/dp/B08D74YFPV/ref=cm_sw_r_awdo_3PVPKKEKZE4ZBNMD35TT

I have a one way valve on my second moisture filter so my YH does not see the bottle pressure until it pumps up to that level and a bit beyond so it overcomes the one way valve. A gun fill works the same way. But you always should start the compressor with the bleed valve open. I reopen it briefly about every 5 minutes to let moisture out. No bottle air is lost when bleeding off moisture due to the one way.

would that filter with a valve be the $40 tuxing on amazon by any chance? or one of joe b’s *cough*, well im gonna refrain from criticizing the mans business model since im sure i dont fully understand all the factors behind his(very high seeming) prices? i ask because im curious if the tuxing filter with valve is a check or a blowoff valve… heres a link.

TUXING PCP compressor Release filter oil-water filter Cotton filter 1set/lot

https://www.amazon.com/dp/B08D74YFPV/ref=cm_sw_r_awdo_3PVPKKEKZE4ZBNMD35TT

Upvote 0

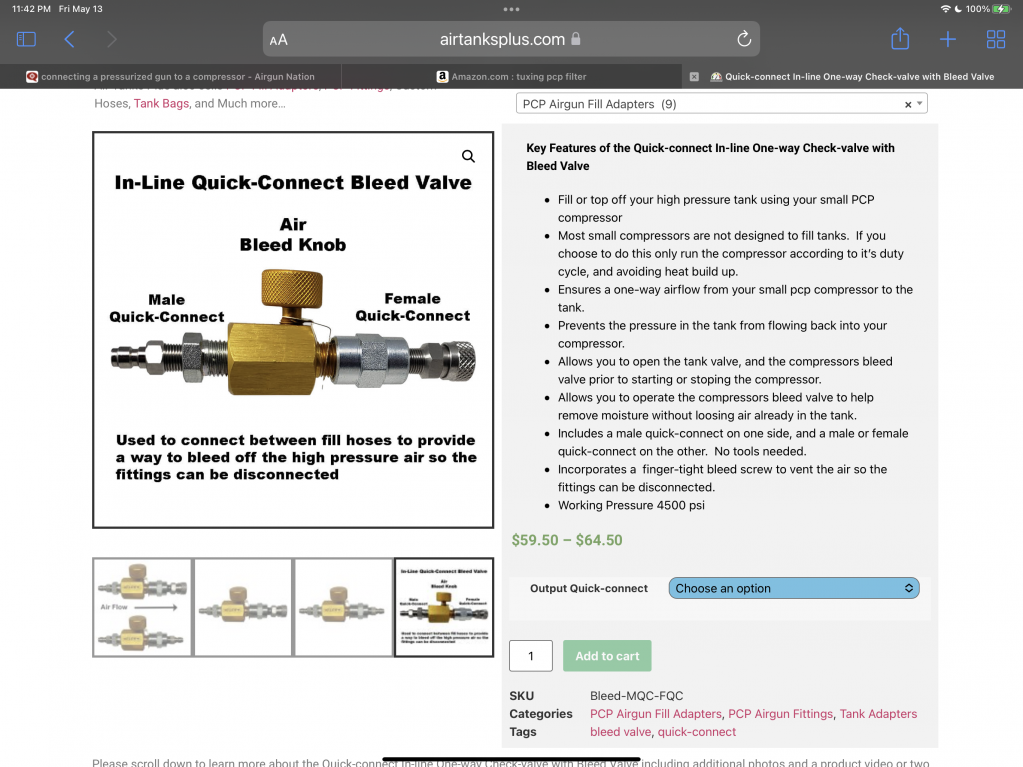

If you’re talking about the silver filter, with the bleeder valve on the side, definitely not that one. I have that one and have never used it do to poor machining, I do not trust it at all. It also does not have a one way check valve, if that’s what you’re asking. Here is one example of a inline check valve, this also has a bleeder valve as well.

Upvote 0

yet again with the clutch and almost instantaneous answer with that helpful icing to boot, thank you scotty! it is indeed, and you totally confirmed the soundness of my hesitation to buy anything made by tuxing after seeing that one review of the gold filter that exploded on the poor fellow. and i mean totally shattered, not just stripped the threads and shot a cap, no like multiple lengthwise fractures sending big ol’ chunks of aluminum flying… if it werent for that review ida prolly ordered one of their 700cc 300 bar bottles in an attempt to save $100, and if not for scotty i may well have went against my better judgement and wasted $40… so moral of the story: Too xings to remember, avoid anything made by tuxing like the plague it is, and the type of valve for this application is the check valve… got it! btw scotty your kitten is absurdly adorable, whats his/her name?

EDIT: possibly unimportant side note/question, anyone got any advice or thoughts on what time of day is best to fill? if im not mistaken warmer air can hold more moisture, and unless youre above the fog line the humidity starts to pick up after the sun sets. but if that were right how come you see dew in the am? and if it really is that warmer air can hold more moisture wouldnt early evening be the best time to fill?

EDIT: possibly unimportant side note/question, anyone got any advice or thoughts on what time of day is best to fill? if im not mistaken warmer air can hold more moisture, and unless youre above the fog line the humidity starts to pick up after the sun sets. but if that were right how come you see dew in the am? and if it really is that warmer air can hold more moisture wouldnt early evening be the best time to fill?

Upvote 0

Just a reminder: make sure any fittings you use are rated for your max pressure or higher, do not try to screw NPT’s and BSPT’s together, they are not meant to go together, especially in high pressure applications. And slow filling is always better.

Upvote 0