Had a friend tell me that his CF bottle threads on the Impact were “galling” after taking it off and on a few dozen times, hard to turn and rough, same putting it back on. The same had happened to me as well.

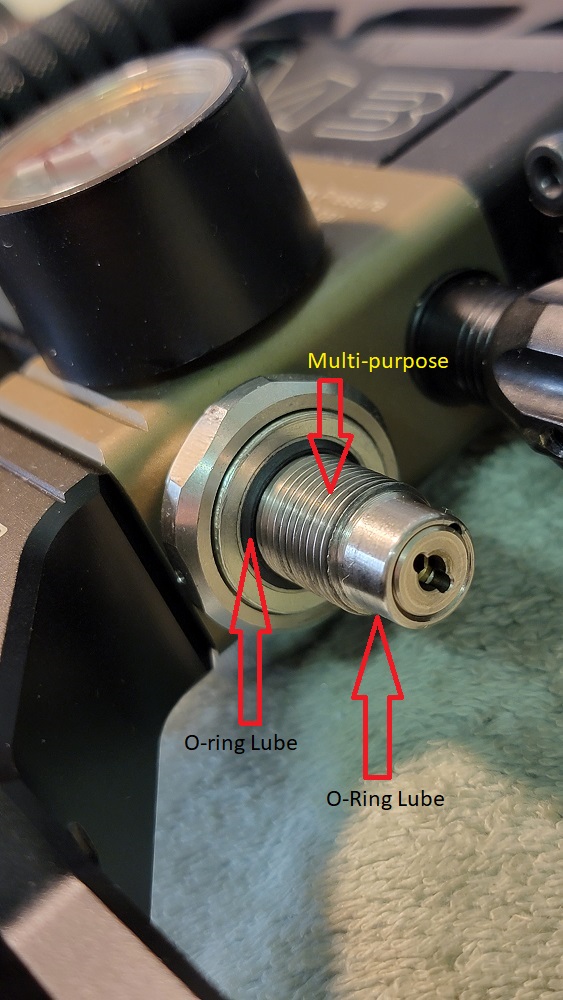

I mentioned to him that Steve Scialli posted on his “Maverick Tune” video what he recommended for lubing both the O-rings and metal to metal thread contacts. This combo has worked flawlessly for me. Clean and re-apply every so often and life is good.

Here is a basic recap.

Clean the surfaces with the solvent of your choice, I use Hopp’s #9. Dry all the surfaces and threads.

Apply each lube to its intended part. Don’t overdo it. A little goes a long way.

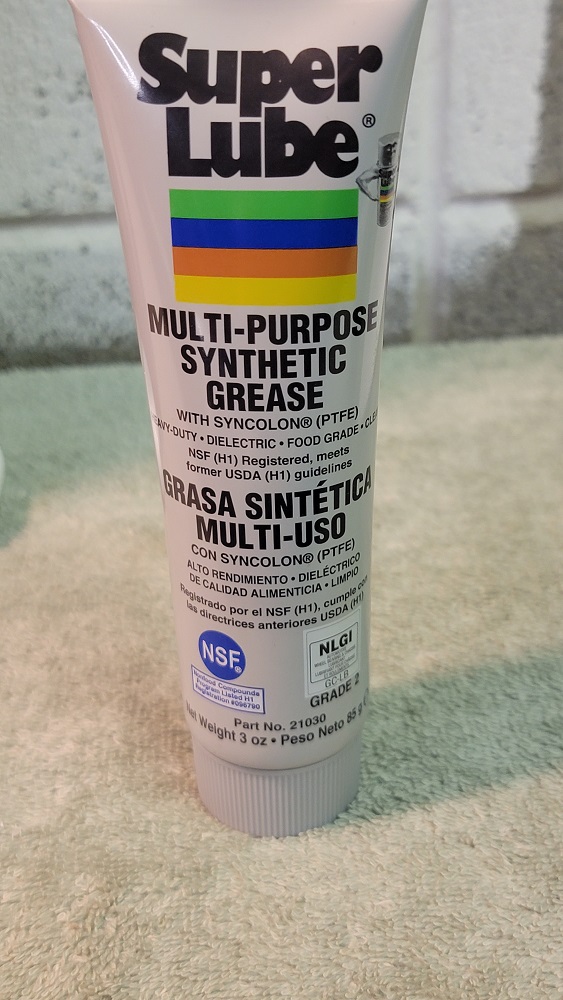

Super Lube Grease is #21030

Super Lube O-ring Grease is #56204

Patrick

I mentioned to him that Steve Scialli posted on his “Maverick Tune” video what he recommended for lubing both the O-rings and metal to metal thread contacts. This combo has worked flawlessly for me. Clean and re-apply every so often and life is good.

Here is a basic recap.

Clean the surfaces with the solvent of your choice, I use Hopp’s #9. Dry all the surfaces and threads.

Apply each lube to its intended part. Don’t overdo it. A little goes a long way.

Super Lube Grease is #21030

Super Lube O-ring Grease is #56204

Patrick