Does anyone know the formula between the capacity of the constant pressure chamber of an airgun and the weight of a lead bullet and the muzzle velocity of a lead bullet, or the connection between them.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Capacity of constant gas chamber

- Thread starter xia8534

- Start date

You can figure it out but I suck at math. A great question for Steve in NC.

Use a step down in-line reg. You would have to have your barrel slugged, and pretty much air gauged slugs. The resistance is measurable. I can't answer the question.

Edit: of course barrel length is paramount to the question also. Valve dwell time, etc. way beyond me.

Use a step down in-line reg. You would have to have your barrel slugged, and pretty much air gauged slugs. The resistance is measurable. I can't answer the question.

Edit: of course barrel length is paramount to the question also. Valve dwell time, etc. way beyond me.

Upvote 0

As you may have noticed from the playful answers so far, your question is one whose answer can fill a textbook.

I’ll attempt a brief answer…

Velocity is influenced mostly by pressure, bullet weight, and barrel length. There are other things playing a role but we will narrow in on these 3 to keep the topic manageable.

The word “pressure” as I’m using it here needs to be thought of in terms of the average pressure, meaning if we want to develop the highest velocity possible, we want to keep the pressure as high as possible for the whole time the bullet is accelerating. To accomplish that goal, we want a large volume of high pressure air and large porting (generous path for air to flow). If instead we have only a small volume of air available, it can become substantially depleted by the time the bullet reaches the muzzle, meaning the average pressure available to accelerate the bullet is greatly diminished.

Meanwhile the bullet weight is of course highly relevant since it’s harder to accelerate a heavy object compared to a light object.

And lastly the barrel length dictates how much of a runway we have to get up to speed.

With that out of the way, I’ll go back to what I think is your main question…how does the volume of the “constant pressure chamber” (plenum) affect the results? We usually talk about this subject in terms of energy…foot*pounds of energy (fpe) or Joules. And since energy is calculated from the velocity and weight, we might say “I’d like to run the JSB 18.1gr at 850fps” which is 29fpe. Generally you will want a plenum that is 0.5 to 1.0 cubic centimeter per foot*pound of energy. So in this example, we would want a plenum chamber somewhere between 14.5cc and 29cc.

Why the range? Well, you want to be as generous as possible but everything is a tradeoff. Anything larger than 1.0cc per fpe is hitting the law of diminishing returns pretty hard. So why not just always use the 1.0cc/fpe guideline? Because for in-tube regulators, you are trading off a portion of the main reservoir to use as the plenum. So big plenum means small reservoir, which in turn means smaller shot count. So in that case a 0.5cc/fpe tends to be the best balance.

I hope this helps!

I’ll attempt a brief answer…

Velocity is influenced mostly by pressure, bullet weight, and barrel length. There are other things playing a role but we will narrow in on these 3 to keep the topic manageable.

The word “pressure” as I’m using it here needs to be thought of in terms of the average pressure, meaning if we want to develop the highest velocity possible, we want to keep the pressure as high as possible for the whole time the bullet is accelerating. To accomplish that goal, we want a large volume of high pressure air and large porting (generous path for air to flow). If instead we have only a small volume of air available, it can become substantially depleted by the time the bullet reaches the muzzle, meaning the average pressure available to accelerate the bullet is greatly diminished.

Meanwhile the bullet weight is of course highly relevant since it’s harder to accelerate a heavy object compared to a light object.

And lastly the barrel length dictates how much of a runway we have to get up to speed.

With that out of the way, I’ll go back to what I think is your main question…how does the volume of the “constant pressure chamber” (plenum) affect the results? We usually talk about this subject in terms of energy…foot*pounds of energy (fpe) or Joules. And since energy is calculated from the velocity and weight, we might say “I’d like to run the JSB 18.1gr at 850fps” which is 29fpe. Generally you will want a plenum that is 0.5 to 1.0 cubic centimeter per foot*pound of energy. So in this example, we would want a plenum chamber somewhere between 14.5cc and 29cc.

Why the range? Well, you want to be as generous as possible but everything is a tradeoff. Anything larger than 1.0cc per fpe is hitting the law of diminishing returns pretty hard. So why not just always use the 1.0cc/fpe guideline? Because for in-tube regulators, you are trading off a portion of the main reservoir to use as the plenum. So big plenum means small reservoir, which in turn means smaller shot count. So in that case a 0.5cc/fpe tends to be the best balance.

I hope this helps!

Upvote 0

As you may have noticed from the playful answers so far, your question is one whose answer can fill a textbook.

I’ll attempt a brief answer…

Velocity is influenced mostly by pressure, bullet weight, and barrel length. There are other things playing a role but we will narrow in on these 3 to keep the topic manageable.

The word “pressure” as I’m using it here needs to be thought of in terms of the average pressure, meaning if we want to develop the highest velocity possible, we want to keep the pressure as high as possible for the whole time the bullet is accelerating. To accomplish that goal, we want a large volume of high pressure air and large porting (generous path for air to flow). If instead we have only a small volume of air available, it can become substantially depleted by the time the bullet reaches the muzzle, meaning the average pressure available to accelerate the bullet is greatly diminished.

Meanwhile the bullet weight is of course highly relevant since it’s harder to accelerate a heavy object compared to a light object.

And lastly the barrel length dictates how much of a runway we have to get up to speed.

With that out of the way, I’ll go back to what I think is your main question…how does the volume of the “constant pressure chamber” (plenum) affect the results? We usually talk about this subject in terms of energy…foot*pounds of energy (fpe) or Joules. And since energy is calculated from the velocity and weight, we might say “I’d like to run the JSB 18.1gr at 850fps” which is 29fpe. Generally you will want a plenum that is 0.5 to 1.0 cubic centimeter per foot*pound of energy. So in this example, we would want a plenum chamber somewhere between 14.5cc and 29cc.

Why the range? Well, you want to be as generous as possible but everything is a tradeoff. Anything larger than 1.0cc per fpe is hitting the law of diminishing returns pretty hard. So why not just always use the 1.0cc/fpe guideline? Because for in-tube regulators, you are trading off a portion of the main reservoir to use as the plenum. So big plenum means small reservoir, which in turn means smaller shot count. So in that case a 0.5cc/fpe tends to be the best balance.

I hope this helps!

Thank you for your answer, this question has been bothering me for 2-3 years and I think it's the most complicated question in airsoft. Your answer is the most detailed and authoritative answer I have seen in such a long time. Because I have been thinking about this problem, the most ideal state is the air inside the constant pressure gas chamber, just enough to push the lead bullet to the exit of the barrel. Because if the air out is too big, it will cause the lead bullet to spiral and waste air. If the air is too small, it will not reach the desired initial velocity and kinetic energy. I think they must have a best match between each other. And can achieve their desired initial speed and kinetic energy, but also will not cause a waste of air and no precision.

Upvote 0

No problem, glad to help.

Regarding your intuitions about expelling too much air being detrimental to accuracy, yes that is a widely accepted concept. There are at least two things going on. One is the item you're hitting on...that the violent rush of air exiting the muzzle may disturb the pellet's stability or nudge it in a random direction. The other thing is added recoil from the larger mass of air being released, together with an increase of vibration from a harder hammer strike. None of these things is good for accuracy.

However there must necessarily be some amount of air expelled behind the pellet. It can't be reduced to zero. In practice, people have discovered that optimum accuracy will usually be achieved when the efficiency is somewhere in the range of 1.0fpe/ci to 1.5fpe/ci. This sort of efficiency translates into the valve being knocked open to release air and then closing before the pellet has traveled 50% of the barrel's length. After the valve closes, the air continues to expand and accelerate the pellet until it leaves the muzzle. Thus there will be some residual pressure...air expelled behind it.

But of course by no means is efficiency any predictor of accuracy by itself. Just that when all other things are coordinated and working well, the efficiency is likely to be in this ballpark.

Regarding your intuitions about expelling too much air being detrimental to accuracy, yes that is a widely accepted concept. There are at least two things going on. One is the item you're hitting on...that the violent rush of air exiting the muzzle may disturb the pellet's stability or nudge it in a random direction. The other thing is added recoil from the larger mass of air being released, together with an increase of vibration from a harder hammer strike. None of these things is good for accuracy.

However there must necessarily be some amount of air expelled behind the pellet. It can't be reduced to zero. In practice, people have discovered that optimum accuracy will usually be achieved when the efficiency is somewhere in the range of 1.0fpe/ci to 1.5fpe/ci. This sort of efficiency translates into the valve being knocked open to release air and then closing before the pellet has traveled 50% of the barrel's length. After the valve closes, the air continues to expand and accelerate the pellet until it leaves the muzzle. Thus there will be some residual pressure...air expelled behind it.

But of course by no means is efficiency any predictor of accuracy by itself. Just that when all other things are coordinated and working well, the efficiency is likely to be in this ballpark.

Upvote 0

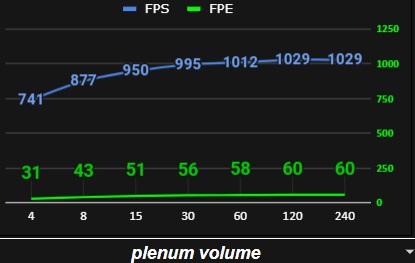

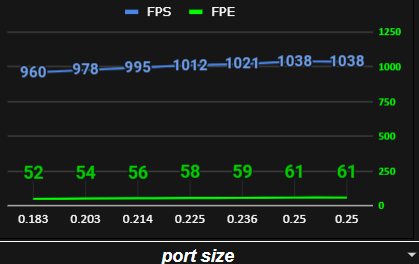

Nervoustrigger summed things up fairly well, I will include a visual representation (graph) of plenum volume change and its effects.

Each graph is for the same rifle (.25 cal marauder, 53 cc plenum, 19" barrel, .225" ports, 140 bar shooting 25.4 gr) all the changes in the one variable shown in each graph. HTH

Plenum volume is in CC's.

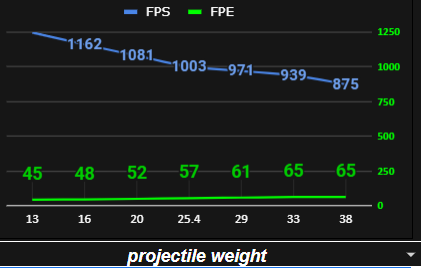

Here is another graph for pellet weight...

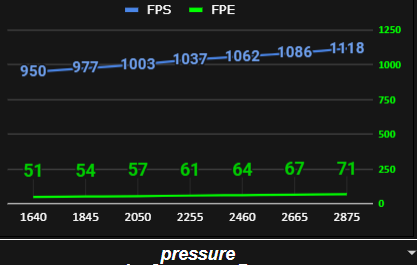

Here is one for pressure..

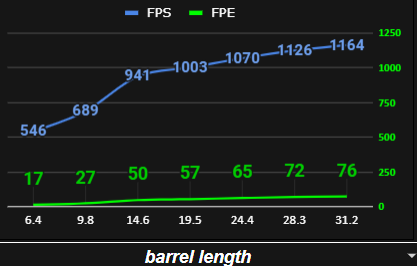

Here is one for barrel length.

and finally one for various port sizes

Each graph is for the same rifle (.25 cal marauder, 53 cc plenum, 19" barrel, .225" ports, 140 bar shooting 25.4 gr) all the changes in the one variable shown in each graph. HTH

Plenum volume is in CC's.

Here is another graph for pellet weight...

Here is one for pressure..

Here is one for barrel length.

and finally one for various port sizes

Upvote 0