Brand new C2T .30.

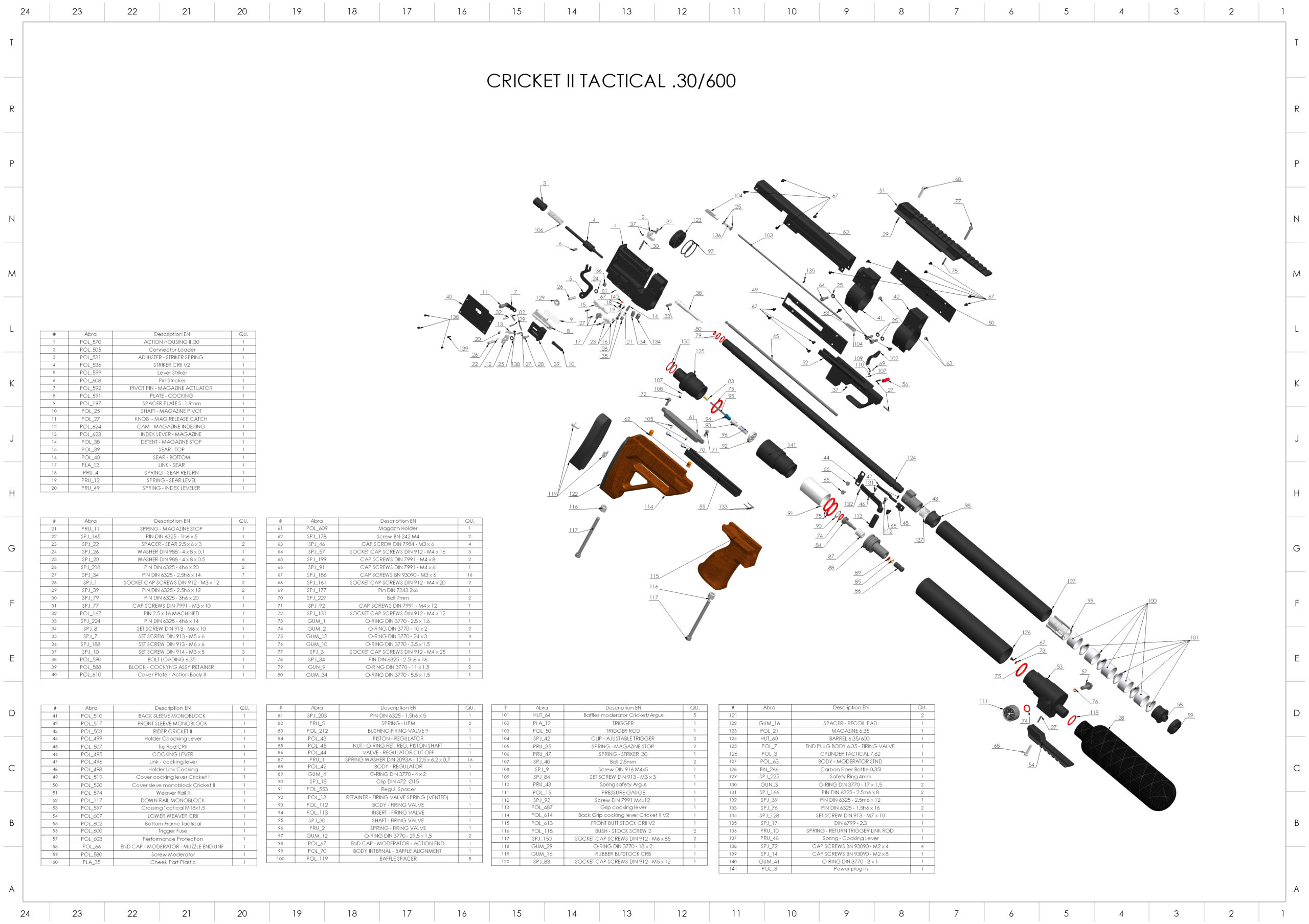

I have determined that #98, #127, and #58 are concentric (the shroud tube and end caps - refer to exploded view below). This is good.

My problem is that #99 is not concentric to those 3 asseembled parts. When I spin the shroud assembly onto the barrel's M14 threads, I can see the shroud outside diameter, and the 1/2-20 threads, spinning eccentrically.

The observed result is that when shooting with a moderator, the group pattern looks like buckshot. When shot with just the shroud, with NO moderator, the group tightens up tremendously (and is also 4" high at 34 yards).

Anyone know how disassemble the shroud? It looks like the end caps are crimped into the shroud tube....but I don't know for sure.

Anyone have any suggestions for a fix? I could shoot it with no moderator but, I'd prefer to use one (and decrease the chances of raising any eyebrows).

I have determined that #98, #127, and #58 are concentric (the shroud tube and end caps - refer to exploded view below). This is good.

My problem is that #99 is not concentric to those 3 asseembled parts. When I spin the shroud assembly onto the barrel's M14 threads, I can see the shroud outside diameter, and the 1/2-20 threads, spinning eccentrically.

The observed result is that when shooting with a moderator, the group pattern looks like buckshot. When shot with just the shroud, with NO moderator, the group tightens up tremendously (and is also 4" high at 34 yards).

Anyone know how disassemble the shroud? It looks like the end caps are crimped into the shroud tube....but I don't know for sure.

Anyone have any suggestions for a fix? I could shoot it with no moderator but, I'd prefer to use one (and decrease the chances of raising any eyebrows).

Last edited: