This topic was formerly titled: "Reviewing an Airgun That Doesn’t Officially Exist: A Peculiar Endeavor"

Posts #1-30 were made prior to 10/13/22. Lots of photos and more identifying information from post #31 and on.

I was recently asked to do an analysis of a new airgun, with one big kicker: I can’t start the public review series prior to the official product launch. With this being the flagship gun of a new name in airgun manufacturing......my response? (after about a half-a-second delay) “heck yeah! but that’s going to be tough.” Still on the phone, my brain was going 90 miles an hour as I think through the logistics of how to make this work. With my reviews in the past, I’ve been transparent, sharing any and everything I have learned; performance, shot strings, accuracy, in-depth photos of the inner workings of the gun etc. And I’ve always done that in nearly real-time, sometimes even on a daily basis. I consider that my standard operating procedure when I get a gun. So my first thought (and how I responded) was that I’ll just do what I do, and save files for all the write-ups, and then release them after the product launch. A day or two goes by and I get a call saying they’ve discussed it, and that I can start the review series, releasing information publicly, as it’s compiled, BUT that I can’t share anything that would identify the gun, again, prior to the official release. They told me to essentially consider this thing a ghost when it comes to identifying details or photos. Still going to be tricky, but might be kinda fun. Almost a reverse review, share all the details, and maybe even some sneak peak, non-identifying photos, and then announce the name of the gun and manufacturer at a later date. Should be interesting. One thought here, some people hate suspense, my wife being one of them. She’ll vote to turn off a movie or stop reading a book as soon as there’s some intrigue. If you’re that type, check back in a few weeks and start at the most recent post and work your way backwards, lol. If you don’t mind some anticipation and have some patience that the big reveal will eventually happen, this review is for you.

And of course, all of this is the airgun industry creating some excitement for a new product. Sometimes that excitement is falsely inflated, but in the case of this particular gun, I think many shooters will be as excited for it as the manufacturer hopes they are. I say that because I’ve read more than one random comment from airgun shooters, wondering aloud why this particular gun isn’t made. Well, now it is, and eventually it’ll be made public and available for purchase. And I also say that I think the excitement will match the hype because I’m personally pretty excited about the gun. And not just because I get to spend some time shooting it, but also because of what it represents. There’s some cool stuff going on with the design, and the premise behind why it was designed the way it was. From what I'm hearing, there are massive plans for aftermarket customization, ALL kinds of goodies available to turn this gun into exactly what the shooter wants. And yes, those goodies represent sales, but they also allow the gun to be configured for very specific uses and moldable for distinct preferences on the shooter side of the equation. So it's been fun to go over the design in this first week and see something and realize, "oh, I see why they did that right there, so that the owner can swap this part out for x to make it be better for NRL or benchrest or field target or come back to or just leave the oem part to be better for hunting or general use " and so on and so forth.

First off, let’s start out with what I’ve so far learned/know about the gun, and what I can share...

(in no particular order)

General (all configurations)...

Specific to the gun I was sent...

10 pull average after some adjustment...

Here are some non-identifying snaps from the trigger mechanism...

Those two bolts come out and that cassette like configuration of sears drops out of the gun. Really unique, TIGHT machining on the various sub assemblies (like this one).

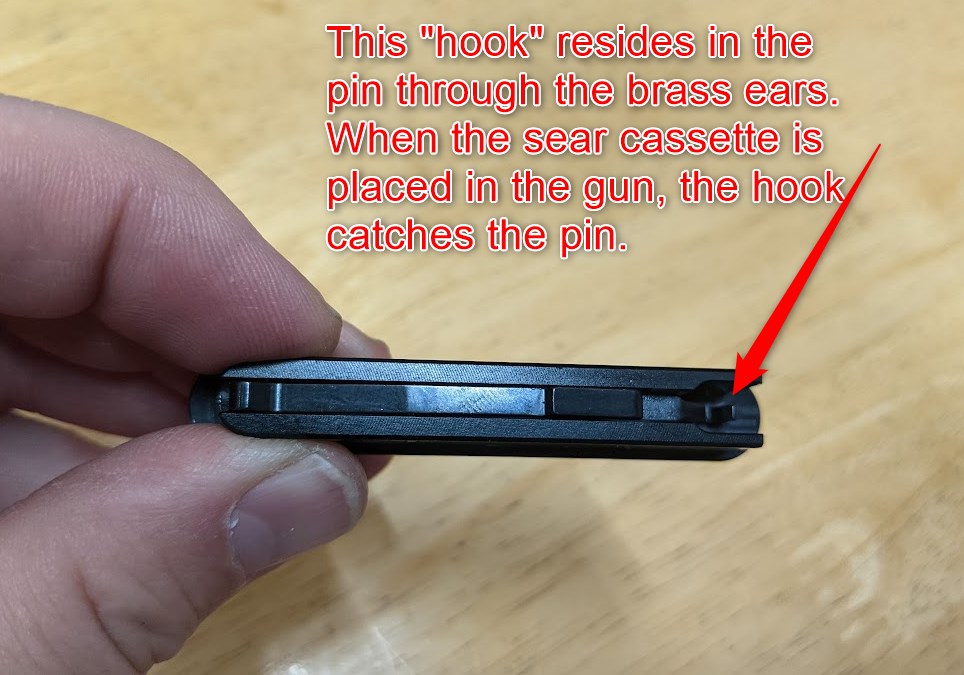

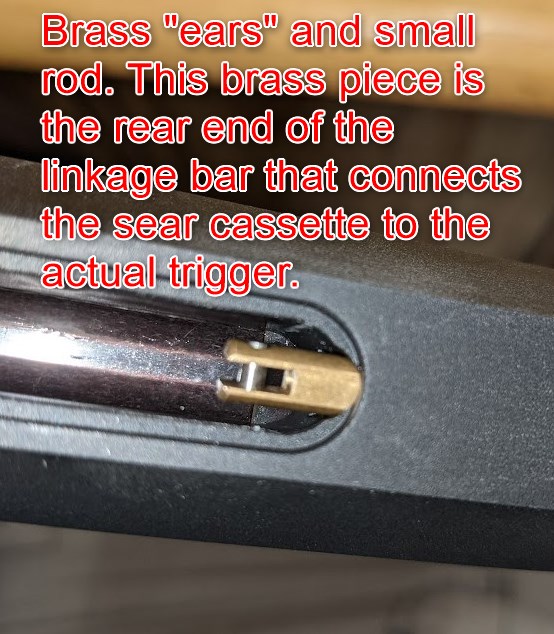

Photos of that sear cassette, from all sides....

While I've had it about a week, I’ve thus far only shot the gun for one fill, from 240-110bar. I didn’t change the reg pressure or even the hammer tension from how it arrived. It came at max hammer tension, determined via the hammer spring tension adjustment. In that one fill, I shot 5 magazines (60 shots). All were taken at paper at 50 yards. The first shot was on paper but needed some scope adjustments. I also swapped scopes after about 2 and a half magazines, determining that the first scope’s reticle was too thick for paper punching. So then I had to zero the second scope. I was also dealing with 15-20mph wind in my completely open back pasture. I’ve got nothing but empty fields on my east side, and of course the wind was coming from the east that day and there is nothing to break up the easterly winds. Really poor accuracy testing conditions but I wanted to shoot the gun bad enough that I went ahead with it. Initially had big plans to do accuracy assessment with about 15 different pellets and slugs, but wind came up just about the time I got everything set up. So, all 5 magazine were just shot with JSB 10.34grain pellets.

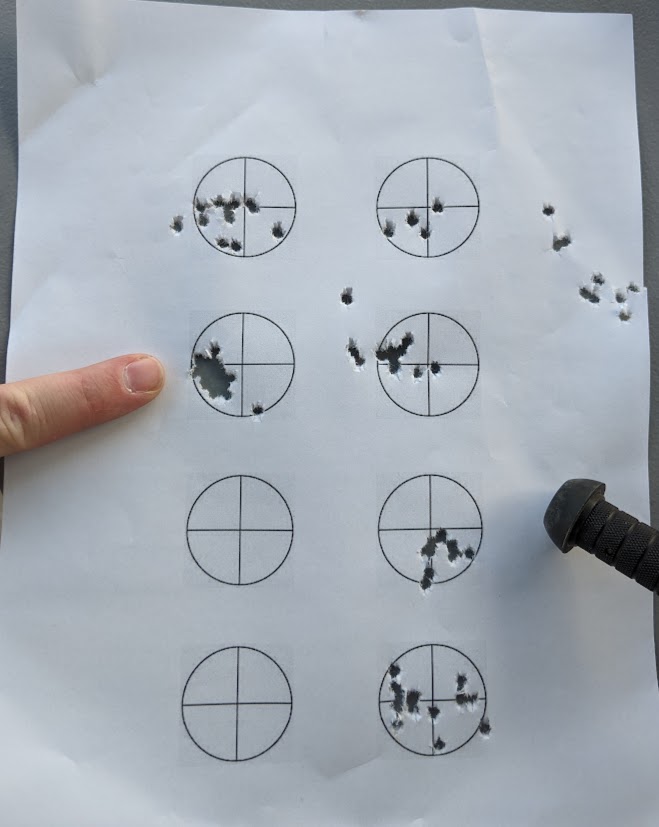

Here’s the first (and only) groups out of the gun…..

Nothing too impressive, until I got to that last group, the one that I’m pointing at. I’ll get to that in a minute though.

I was shooting over a chrono and was pleasantly surprised to see how consistent the gun is. First magazine had an ES of 9 and an average of 937fps, just a bit hot for sub 20fpe field target. The next 3 magazines all were above 925 and below 937, so, 48 shots with an ES of 12. Before the fifth magazine I was right under 120 bar so expected fps to come down. They did, like a rock. That last 12 shots was from 923 down to 895, and that’s the group that I’m pointing at. So, the barrel seems to like the 10.34s at probably 910-915 fps MUCH better than it did at 930fps. Pretty sure it's got too much hammer tension. I suspect that coming down on that hammer tension adjustment a couple clicks, maybe around the 15 mark, won't lose much fps but likely gain in shot count. I'll eventually drill down on all the settings and arrive at some reg pressures/hammer tensions/projectiles that are easily repeatable and fit a couple different uses, as well as providing the high level of accuracy that I'm after.

The current plan is to test what I consider light pellets (7.87-9.57grains).

I'll run a different test group of "heavy" pellets...

And finally, I'll see how it does with the slugs that I have on hand...

There's a bit of overlap in my planned projectile testing with different brandings coming from same manufacturer, but sometimes a different batch will shoot light and day different so it's worth it to try them out. It'll also serve as an indicator of whether or not this barrel is going to be cantankerous about specific batches, or if it's going to play nice and be tolerant of a wide range of projectiles/batches.

REALLY early in this whole process but so far really liking what I’m seeing. I’m very likely to address any of the aforementioned details in much greater depth as I spend time with it. And it sounds like they're giving me a pretty loose leash, both in regards to what I share about the gun, the direction(s) I take with it, and the length of time I have to do all that. BUT, we'll get there, the next step is to do simple accuracy assessments with a wide range of projectiles.

Unfortunately I won’t be able to play 20 questions about the gun. Ie, I can neither confirm nor deny any guesses, assumptions, declarations, etc that come about because of this review in the timeframe between now and the manufacturer’s official product launch. I will, however, answer (as best I can) any questions that don’t identify the gun (general performance, “how does it shoot X pellet?” etc).

Posts #1-30 were made prior to 10/13/22. Lots of photos and more identifying information from post #31 and on.

I was recently asked to do an analysis of a new airgun, with one big kicker: I can’t start the public review series prior to the official product launch. With this being the flagship gun of a new name in airgun manufacturing......my response? (after about a half-a-second delay) “heck yeah! but that’s going to be tough.” Still on the phone, my brain was going 90 miles an hour as I think through the logistics of how to make this work. With my reviews in the past, I’ve been transparent, sharing any and everything I have learned; performance, shot strings, accuracy, in-depth photos of the inner workings of the gun etc. And I’ve always done that in nearly real-time, sometimes even on a daily basis. I consider that my standard operating procedure when I get a gun. So my first thought (and how I responded) was that I’ll just do what I do, and save files for all the write-ups, and then release them after the product launch. A day or two goes by and I get a call saying they’ve discussed it, and that I can start the review series, releasing information publicly, as it’s compiled, BUT that I can’t share anything that would identify the gun, again, prior to the official release. They told me to essentially consider this thing a ghost when it comes to identifying details or photos. Still going to be tricky, but might be kinda fun. Almost a reverse review, share all the details, and maybe even some sneak peak, non-identifying photos, and then announce the name of the gun and manufacturer at a later date. Should be interesting. One thought here, some people hate suspense, my wife being one of them. She’ll vote to turn off a movie or stop reading a book as soon as there’s some intrigue. If you’re that type, check back in a few weeks and start at the most recent post and work your way backwards, lol. If you don’t mind some anticipation and have some patience that the big reveal will eventually happen, this review is for you.

And of course, all of this is the airgun industry creating some excitement for a new product. Sometimes that excitement is falsely inflated, but in the case of this particular gun, I think many shooters will be as excited for it as the manufacturer hopes they are. I say that because I’ve read more than one random comment from airgun shooters, wondering aloud why this particular gun isn’t made. Well, now it is, and eventually it’ll be made public and available for purchase. And I also say that I think the excitement will match the hype because I’m personally pretty excited about the gun. And not just because I get to spend some time shooting it, but also because of what it represents. There’s some cool stuff going on with the design, and the premise behind why it was designed the way it was. From what I'm hearing, there are massive plans for aftermarket customization, ALL kinds of goodies available to turn this gun into exactly what the shooter wants. And yes, those goodies represent sales, but they also allow the gun to be configured for very specific uses and moldable for distinct preferences on the shooter side of the equation. So it's been fun to go over the design in this first week and see something and realize, "oh, I see why they did that right there, so that the owner can swap this part out for x to make it be better for NRL or benchrest or field target or come back to or just leave the oem part to be better for hunting or general use " and so on and so forth.

First off, let’s start out with what I’ve so far learned/know about the gun, and what I can share...

(in no particular order)

General (all configurations)...

- Chassis gun, no wood or laminate

- Modular nature

- “Bullpup” layout

- Biathlon cocking lever, located right above the trigger (no rear-cocking bullpup here)

- Bottle gun- and actually a valved bottle, so it can be unscrewed slightly to segregate air supply for regulator adjustments, without dumping the whole bottle (air within the plenum/innards needs to be shot out after unscrewing bottle and prior to lowering reg pressure)

- Regulated, and externally adjustable, as described above

- 250 bar max fill

- Lothar Walther barrels

- Barrel kits will be available (caliber swaps, different lengths, etc)

- All calibers have the same valve, so going from a .177 to a .25, for example, is possible

- Trigger linkages and sears are in a unique cassette-like format

- Being a bullpup, obviously has linkages, but multiple adjustments at the trigger (first stage tension, etc)

- Main sears at rear of gun drop out like a cassette, parts are finely machined, no obviously stamped components, everything but the pins are hard-anodized

- There is a cover in the frame of the gun, above the trigger, that lets a guy see what they’re adjusting (when cover is removed)

- Shrouded barrels and shroud has 1/2x20 standard threads at muzzle end to allow for addition of moderator

- Dual manometers, one on each side of the gun, left side shows reg pressure, right side shows bottle pressure (I might have to throw a digital gauge on in place of the analog reg gauge, just for giggles!)

- deleted

- Male foster for filling the gun has a sintered filter down inside, to keep particulate from getting in the gun (nice addition)

- Adjustable cheek piece (first thing I adjusted on the gun)

- Adjustable butt-plate, for height (second thing I adjusted on the gun)

- Picatinny scope rail, and plenty long for various levels of eye relief/types of scope

- Side pic rails present as well

- Ventral pic rail also (bipod!!!)

- Comes with BEEFY hard case (think airline approved gun case, okay I don’t know if it really is, but it has that look)

- Comes with various allen keys, spare orings, fittings to get air in the tank

- Surprised to see that it has paperwork, so the manufacturer is far enough along in the new product release process that they have stuff printed

- MSRP is what most people will consider mid-tier, although I’ve been inside guns in the same price range that weren’t machined as well as this one appears to be nor did they give an as overall "solid" impression (the read between the lines there is that it SEEMS like it's going to be a lot of gun for the money, partly on it's own merit as a stand-alone gun, but also largely due to the planned aftermarket support/customization options)

Specific to the gun I was sent...

- .177 and obviously a “compact” configuration

- OAL without a moderator = 26”

- OAL with a 4 and 5/8inch mod = 30 and 1/8 inches

- 300cc bottle

- 12 shot magazine, loading 10.34gr pellets I remarked at how deep the mag wells are

- Reg pressure came at 120bar

- I would guess it weighs around 6-7lbs without a scope

- OEM trigger pull-10 shot average was 1lb 4.5oz

- I was able to adjust it down to a 10 shot average of 9.1oz, I suspect it’ll lighten up and lose another couple ounces with use

10 pull average after some adjustment...

Here are some non-identifying snaps from the trigger mechanism...

Those two bolts come out and that cassette like configuration of sears drops out of the gun. Really unique, TIGHT machining on the various sub assemblies (like this one).

Photos of that sear cassette, from all sides....

While I've had it about a week, I’ve thus far only shot the gun for one fill, from 240-110bar. I didn’t change the reg pressure or even the hammer tension from how it arrived. It came at max hammer tension, determined via the hammer spring tension adjustment. In that one fill, I shot 5 magazines (60 shots). All were taken at paper at 50 yards. The first shot was on paper but needed some scope adjustments. I also swapped scopes after about 2 and a half magazines, determining that the first scope’s reticle was too thick for paper punching. So then I had to zero the second scope. I was also dealing with 15-20mph wind in my completely open back pasture. I’ve got nothing but empty fields on my east side, and of course the wind was coming from the east that day and there is nothing to break up the easterly winds. Really poor accuracy testing conditions but I wanted to shoot the gun bad enough that I went ahead with it. Initially had big plans to do accuracy assessment with about 15 different pellets and slugs, but wind came up just about the time I got everything set up. So, all 5 magazine were just shot with JSB 10.34grain pellets.

Here’s the first (and only) groups out of the gun…..

Nothing too impressive, until I got to that last group, the one that I’m pointing at. I’ll get to that in a minute though.

I was shooting over a chrono and was pleasantly surprised to see how consistent the gun is. First magazine had an ES of 9 and an average of 937fps, just a bit hot for sub 20fpe field target. The next 3 magazines all were above 925 and below 937, so, 48 shots with an ES of 12. Before the fifth magazine I was right under 120 bar so expected fps to come down. They did, like a rock. That last 12 shots was from 923 down to 895, and that’s the group that I’m pointing at. So, the barrel seems to like the 10.34s at probably 910-915 fps MUCH better than it did at 930fps. Pretty sure it's got too much hammer tension. I suspect that coming down on that hammer tension adjustment a couple clicks, maybe around the 15 mark, won't lose much fps but likely gain in shot count. I'll eventually drill down on all the settings and arrive at some reg pressures/hammer tensions/projectiles that are easily repeatable and fit a couple different uses, as well as providing the high level of accuracy that I'm after.

The current plan is to test what I consider light pellets (7.87-9.57grains).

I'll run a different test group of "heavy" pellets...

And finally, I'll see how it does with the slugs that I have on hand...

There's a bit of overlap in my planned projectile testing with different brandings coming from same manufacturer, but sometimes a different batch will shoot light and day different so it's worth it to try them out. It'll also serve as an indicator of whether or not this barrel is going to be cantankerous about specific batches, or if it's going to play nice and be tolerant of a wide range of projectiles/batches.

REALLY early in this whole process but so far really liking what I’m seeing. I’m very likely to address any of the aforementioned details in much greater depth as I spend time with it. And it sounds like they're giving me a pretty loose leash, both in regards to what I share about the gun, the direction(s) I take with it, and the length of time I have to do all that. BUT, we'll get there, the next step is to do simple accuracy assessments with a wide range of projectiles.

Unfortunately I won’t be able to play 20 questions about the gun. Ie, I can neither confirm nor deny any guesses, assumptions, declarations, etc that come about because of this review in the timeframe between now and the manufacturer’s official product launch. I will, however, answer (as best I can) any questions that don’t identify the gun (general performance, “how does it shoot X pellet?” etc).

Last edited: