Is felt the best option for lining the inside of the FX factory moderator or are there some better options out there?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best material for modifying the FX hollow moderator.

- Thread starter Platebar14

- Start date

- Status

- Not open for further replies.

Is felt the best option for lining the inside of the FX factory moderator or are there some better options out there?

I used cone baffles and some felt toward the tip retained by a hardware fabric cageIs felt the best option for lining the inside of the FX factory moderator or are there some better options out there?

Upvote 0

I've seen those on the Trenier site--looks like a nice upgradeTrenier Outdoors sells 3d printed inserts for hollow FX cans

Upvote 0

I was just getting ready to post a question for this but nobody mentions anything about the .30 boss hollow end. Looks to be about 3.5 inches I could fill. I heard or read somewhere a comment about a hair curler wrapped in felt? Any other suggestions?

Upvote 0

People really love their weirauch cans. They basically have a felt wrapped curler, then a washer/baffle, felt wrapped curler, washer/baffle and a final felt wrapped curler. I'm pretty sure that's it. I have one after that pattern. it's serving me well on a pistol. I might also point out my DFL's seem similar. Avery nice monocore wrapped in wire mesh and felt. I also like every piece I can to be airgun only. I think plastic curlers, plastic baffles, and felt work to be both quiet and firearm unfriendly. You can grab some curlers and felt pretty cheap at the store and if you hate it, you're just out a few bucks.

Upvote 0

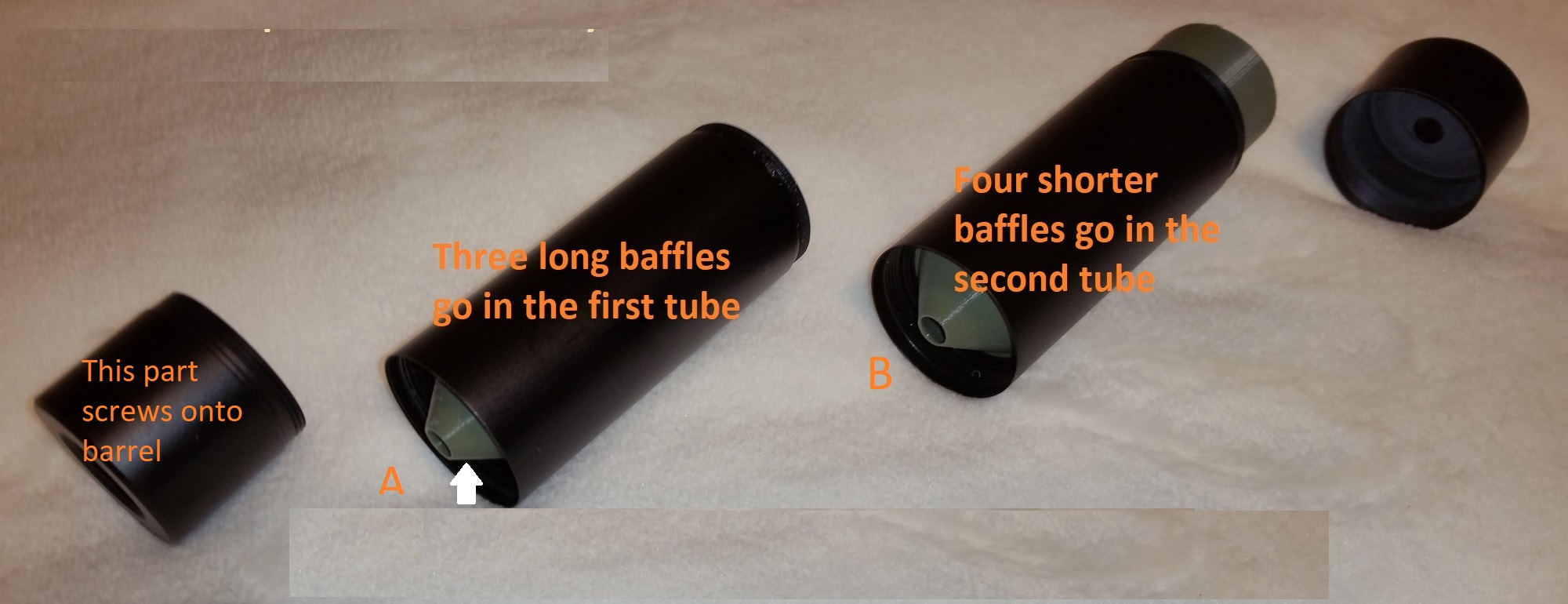

3d printed cones are best with nothing else. Here's a link to download my files for .25 caliber or less. They can be used for .30 by opening the hole with a step drill. Two 75mm long center sections work best for higher power guns. This double center setup made my 132fpe impact as quiet as a 30fpe .22 until the slug hit anyway.

https://www.thingiverse.com/thing:4914398 longer baffles

https://www.thingiverse.com/thing:4914370 shorter baffles. Follow instructions in the pictures.

https://www.thingiverse.com/thing:4914398 longer baffles

https://www.thingiverse.com/thing:4914370 shorter baffles. Follow instructions in the pictures.

Upvote 0

I did this to one and it seemed to quiet things down a bit. At least it changed the tone so it seemed quieter anyway.

I also picked up some of the cone baffles somewhere which seemed to do a little more.

https://www.ebay.com/itm/303946465366

https://www.ebay.com/itm/115390515018

I also picked up some of the cone baffles somewhere which seemed to do a little more.

https://www.ebay.com/itm/303946465366

https://www.ebay.com/itm/115390515018

Last edited:

Upvote 0

The Ataman, BP17 also comes with a hollow tube that's, I guess supposed to quiet the bark of the shot...but doesn't !

I tried several different ways of lowering the sound, nothing worked as well as I'd hoped.

Then I got a proverbial...wild hair.

With three RC car spur gears (snug fit in the tube, six pen springs, three pieces of allthread, a few nuts, later... I have a suppressor that actually works, quite well. One of the gears is stationary, the other two will move with the pressure of the shot. Expanding the chamber size actually. The springs act to control the movement of the gears and to return the gears to their...as designed position.

Yeah, it works very well. No I didn't take any photos.

The expanding chamber idea is "similar..." to the Daystate, factory baffles that I put into the shroud of my RTI Compact. With a very light spring holding the baffles in place, I have no need for an external suppressor to quiet my RTI Compact. My cats don't even mind the sound from this gun !

I also modified my Daystate Pulsar and Renegade, by cutting the spring shorter to allow the baffles to move during the shot. Yes, this helpes quiet my two Daystate rifles also.

Mike

I tried several different ways of lowering the sound, nothing worked as well as I'd hoped.

Then I got a proverbial...wild hair.

With three RC car spur gears (snug fit in the tube, six pen springs, three pieces of allthread, a few nuts, later... I have a suppressor that actually works, quite well. One of the gears is stationary, the other two will move with the pressure of the shot. Expanding the chamber size actually. The springs act to control the movement of the gears and to return the gears to their...as designed position.

Yeah, it works very well. No I didn't take any photos.

The expanding chamber idea is "similar..." to the Daystate, factory baffles that I put into the shroud of my RTI Compact. With a very light spring holding the baffles in place, I have no need for an external suppressor to quiet my RTI Compact. My cats don't even mind the sound from this gun !

I also modified my Daystate Pulsar and Renegade, by cutting the spring shorter to allow the baffles to move during the shot. Yes, this helpes quiet my two Daystate rifles also.

Mike

could i please ask how u reached up to 130 fpe? mk2 with 720 power plenum and heavy springs, coils, hammer etc here! oh and im a shortie compact as well!3d printed cones are best with nothing else. Here's a link to download my files for .25 caliber or less. They can be used for .30 by opening the hole with a step drill. Two 75mm long center sections work best for higher power guns. This double center setup made my 132fpe impact as quiet as a 30fpe .22 until the slug hit anyway.

https://www.thingiverse.com/thing:4914398 longer baffles

https://www.thingiverse.com/thing:4914370 shorter baffles. Follow instructions in the pictures.

View attachment 269957View attachment 269958

Upvote 0

Delrin K-Baffles.......

These are for my DFL Extender....

So You can resize the dimensions to fit the FX hollow Mod......

These are for my DFL Extender....

So You can resize the dimensions to fit the FX hollow Mod......

Upvote 0

I used an external plenum on a modified rear block in conjunction with my eccentric plenum design. 700mm barrel with modified transfer port and probe. Larger valve seat, hammer weight and other small things. Regulator at 150 bar.could i please ask how u reached up to 130 fpe? mk2 with 720 power plenum and heavy springs, coils, hammer etc here! oh and im a shortie compact as well!

Upvote 0

They are aluminum and anodized. But printing baffles is dirt cheap for just the cost of the filament used. I have a cone baffle design that each baffle screws together thats just over 2.0 OD and thats less than $1.00 per baffle to print for just the raw material. I dont know how much the electricity cost to print it but thats still pretty cheap even including the power.Just give the dimensions to one of the guys who print moderators and he can make you those baffles for about $5.00 each plus shipping.

Sheese $99 bucks?

Upvote 0

You cant design a baffle set for it its a stacked system. The baffles screw together. I do all my designing, machining or printing. I am currently designing a reflex design for my crown mk2 with a 320mm .177 barrel. I like it short so I want a mod thats short as possible.What are the internal dimensions of that moderator? I will design a baffle set for it which can be printed on an FDM printer and drop the design (stl files) here.

Last edited:

Upvote 0

No I am saying the baffles screw together forming the mod. You are familiar with the impulse air mod and donny fl mods correct?

Upvote 0

I've been printing them for years. No reason to screw the baffles together they friction fit inside the tube. Doesn't need a spring or anything else and I run tight clearance to the slug. First shot the pressure seats them to the front where they stay. I even use the fx can on a gauntlet with an adapter I made.You cant design a baffle set for it its a stacked system. The baffles screw together. I do all my designing, machining or printing. I am currently designing a reflex design for my crown mk2 with a 320mm .177 barrel. I like it short so I want a mod thats short as possible.

Upvote 0

I am not sure what you are talking about. You quoted a post of mine where I talked about a mod I designed that has a 2.0 OD. You asked me what the internal dimension was so you could design baffles for it. If thats the mod you are asking about now then no you cant design baffles for it and no its not just an empty space. The baffles screw together forming the mod. How are you going to make baffles to stick into baffles? Second why would you want to?I am familiar with some moderators but not all. I thought we were talking about a moderator that shipped with no internals, just an empty space. I mean if someone can create baffles for it then I can as well, no?

Upvote 0

You guys are killing me with this bs. I have been machining baffles for a very long time and printing. I have made that design of baffles a long time ago and thats nothing like the design I made that screws together. Are you going to tell donny fl or impulse air to stop making mods that screw together because they dont need to since they can be made with simple tubes and baffles that slide into said tube? No? Then quit telling me how I should be designing my mods. You are not showing me anything I didnt know or do years ago. I am talking about a mod that screws together forming the baffles and main body. THE BAFFLE AND BODY ARE ONE PIECE AND YOU SCREW THEM TOGETHER TO FORM WHAT EVER LENGTH MOD YOU WANT. Maybe thats clear enoughI've been printing them for years. No reason to screw the baffles together they friction fit inside the tube. Doesn't need a spring or anything else and I run tight clearance to the slug

Upvote 0

- Status

- Not open for further replies.