G

Guest

Guest

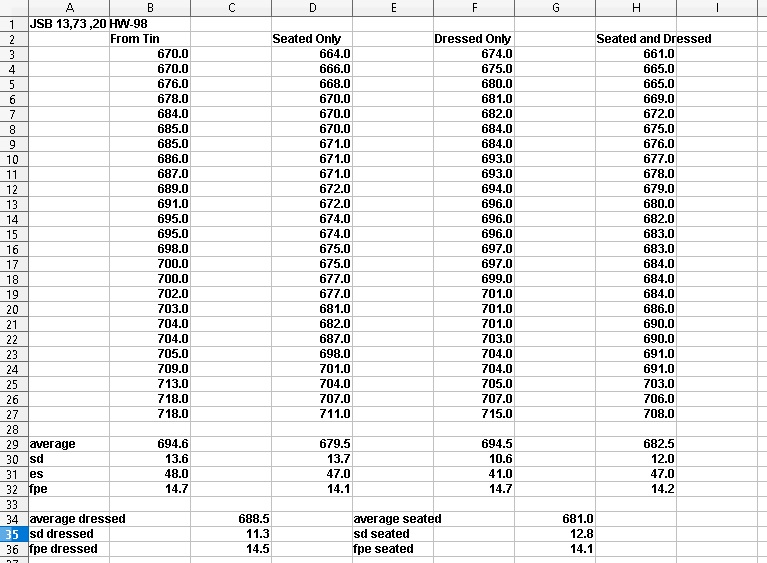

One of the old Beeman pellet tools was used in this study.

Seated means I set the pellet into the barrel to the depth the tool would push it.

Dressed means I used the tool to round the skirt before I shot the pellet.

The pellet was 13.73 grain JSB in .20 cal.

The rifle was an HW-98 which had not been completely shot in at that point.

YMMV

There is nothing really drastic here but it is interesting to see a 12% improvement in SD when dressing skirts before firing and a three percent reduction in power when seating the pellet with the tool.

Seated means I set the pellet into the barrel to the depth the tool would push it.

Dressed means I used the tool to round the skirt before I shot the pellet.

The pellet was 13.73 grain JSB in .20 cal.

The rifle was an HW-98 which had not been completely shot in at that point.

YMMV

There is nothing really drastic here but it is interesting to see a 12% improvement in SD when dressing skirts before firing and a three percent reduction in power when seating the pellet with the tool.