Dear friends, users of EDgun products, haters of EDgun products, those who doesn’t care but is interested in what, in fact, happened in UK in the beginning of this year.

Shortly:

, for those who wants to make the precise translation – Google translator will help you, no doubt.

, for those who wants to make the precise translation – Google translator will help you, no doubt.

For those who wants to know only the final parts it sounds this way:

Unfortunately, the moisture with some addings (like oil and so on) in the conditions of the high pressure can be very aggressive to the alum alloy.

That is why I, personally, avoid using undried air and use ONLY air from the tanks, filled at the fire department or dive centers, who use air for breathing.

My recommendation to those who has no possibility to use dry air and have to use small compressors or hand pumps – use the best dryer you can find and make the check-out of the inside surface of the reservoirs on the constant base.

From my side, as the manufacturer, I cannot see any mistakes, which was confirmed by this expertise and with my light heart keep going on making the guns using all necessary measures to make them as safe as possible.

With the best regards

Ed

Shortly:

- There was an information bout the case in beginning of February 2023.

- Dave, the owner of exploded L2, was so kind that arranged the shipment of the remains to Russia.

- I got them in the beginning of the summer and then made the contract with the special laboratory to make the test.

- At the end of summer I got the results.

For those who wants to know only the final parts it sounds this way:

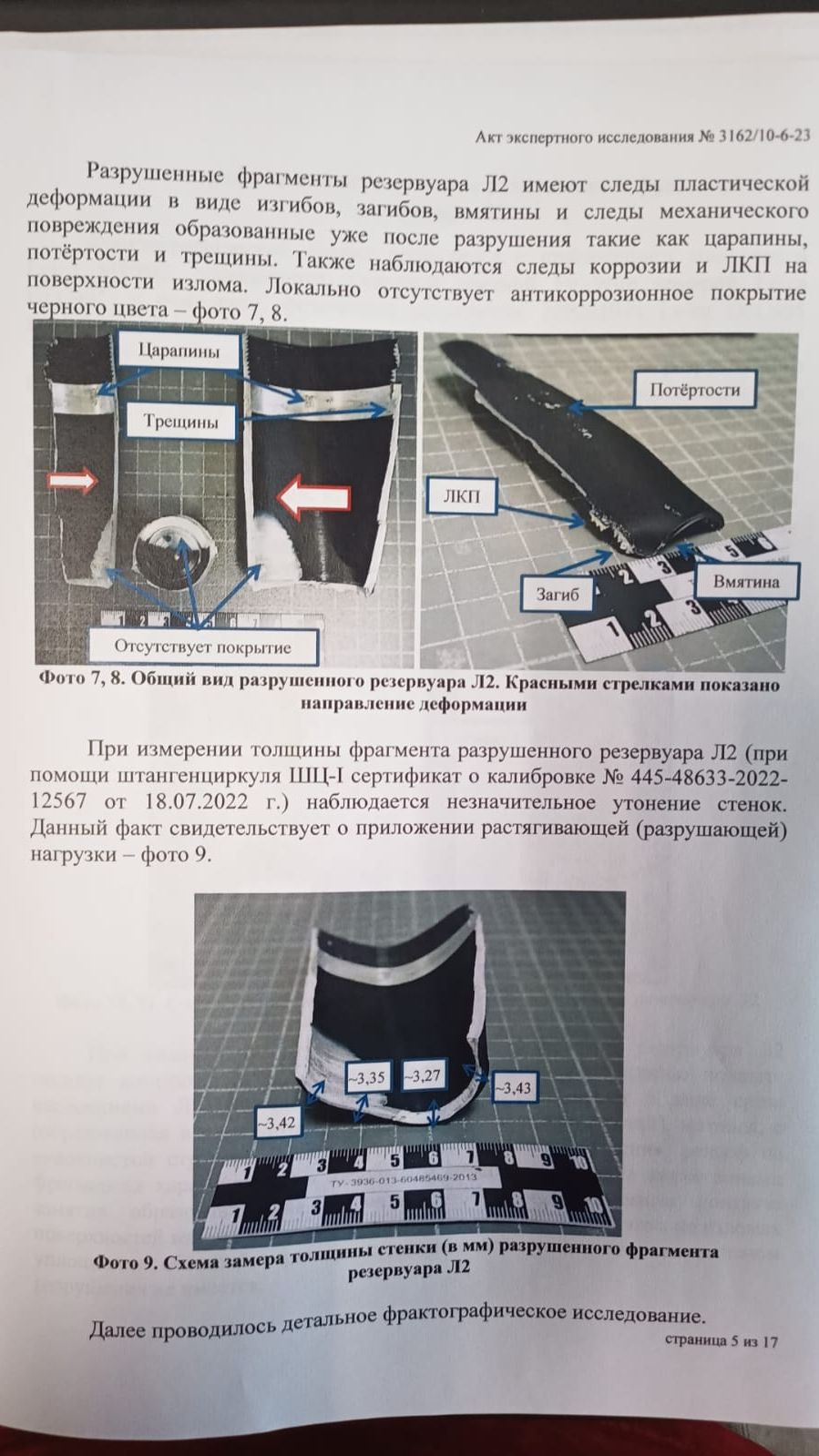

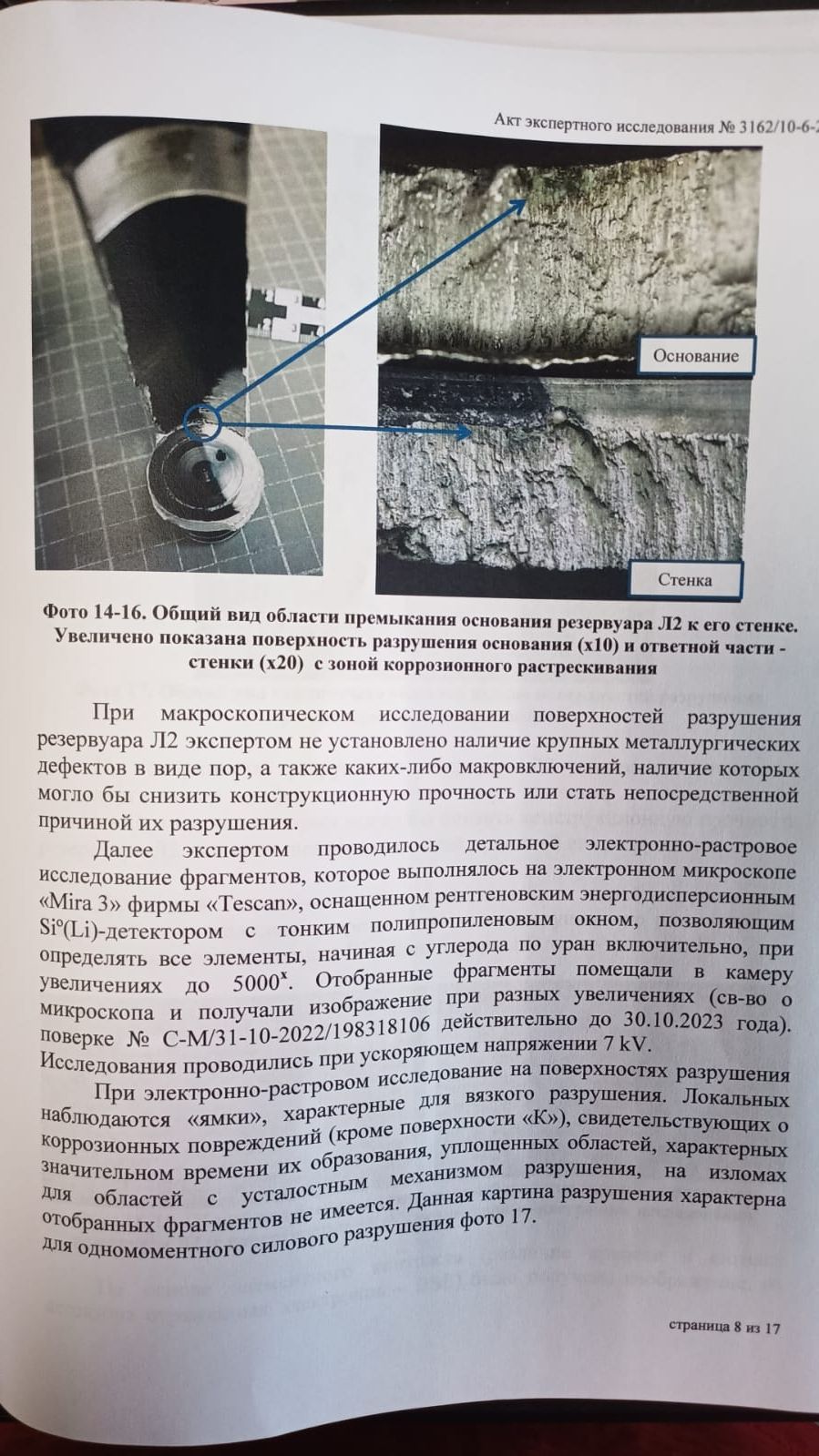

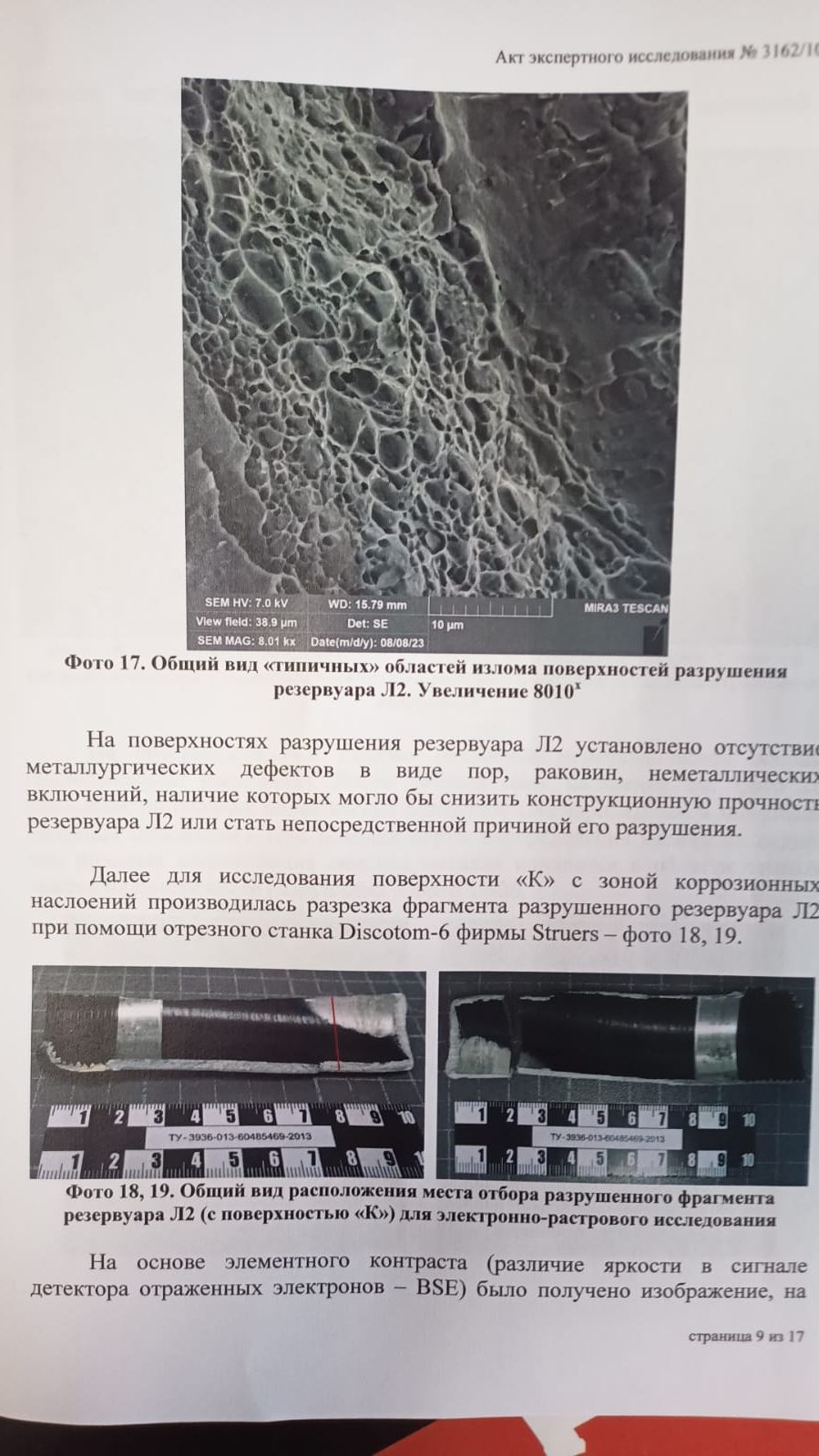

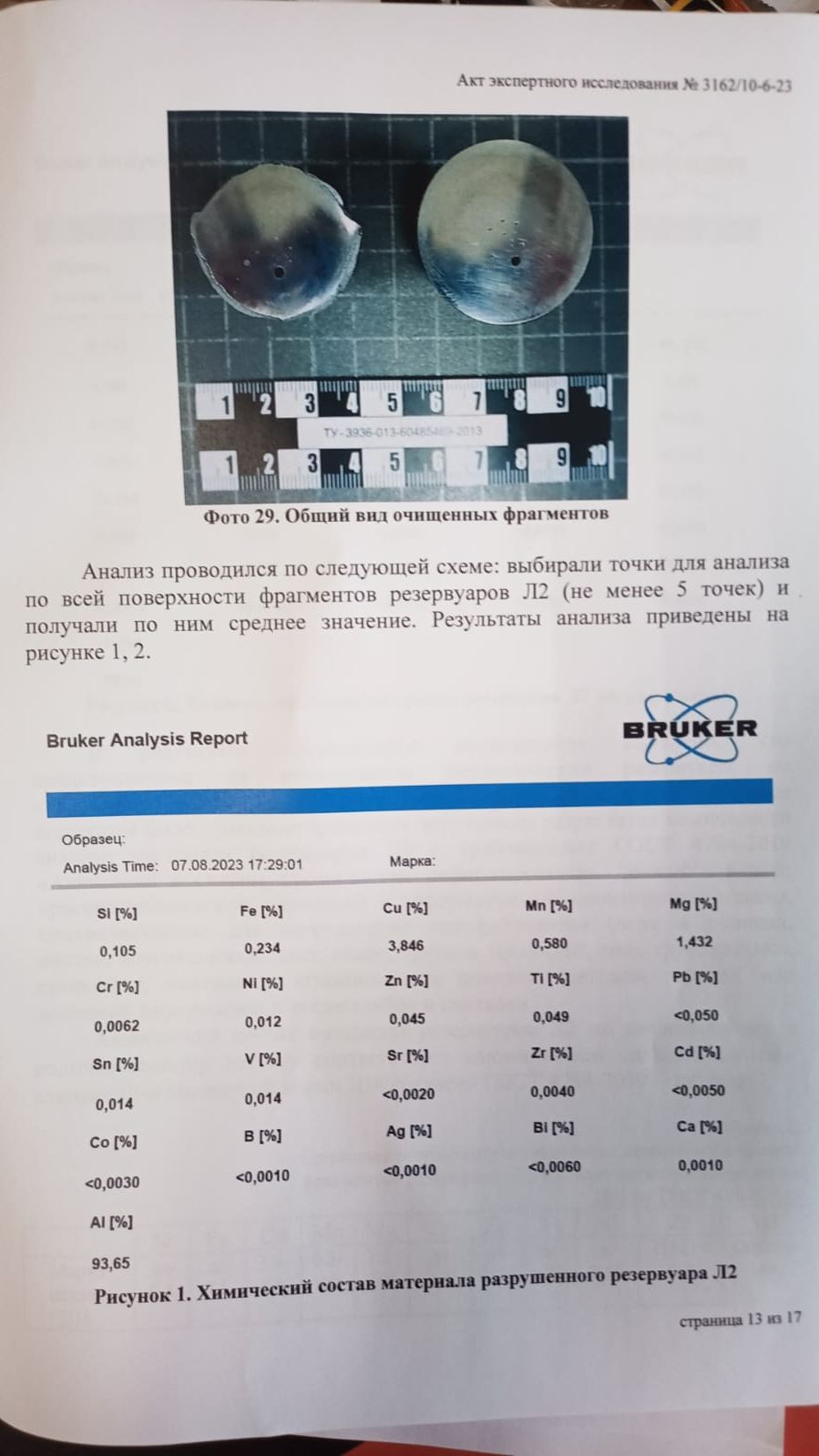

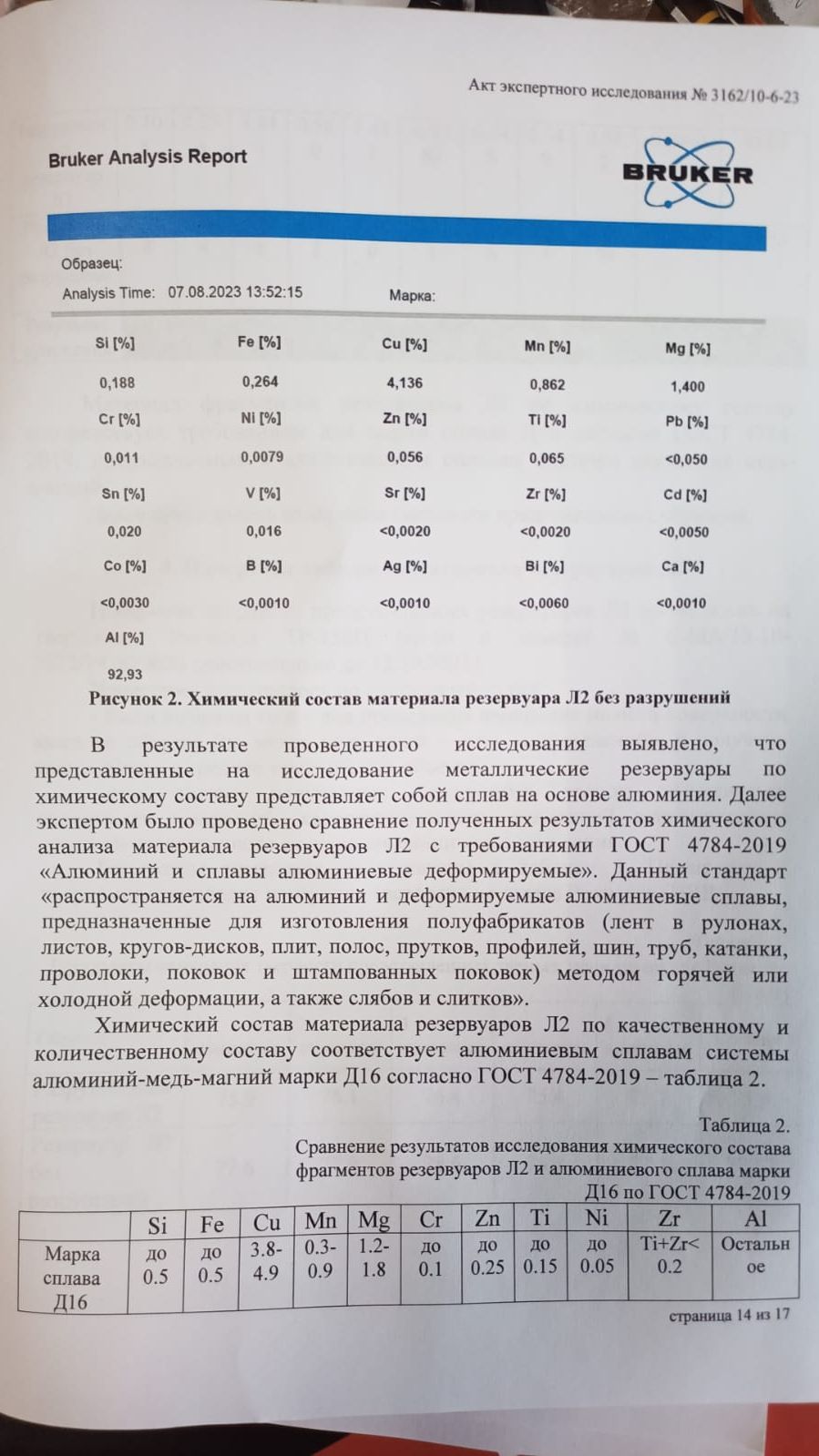

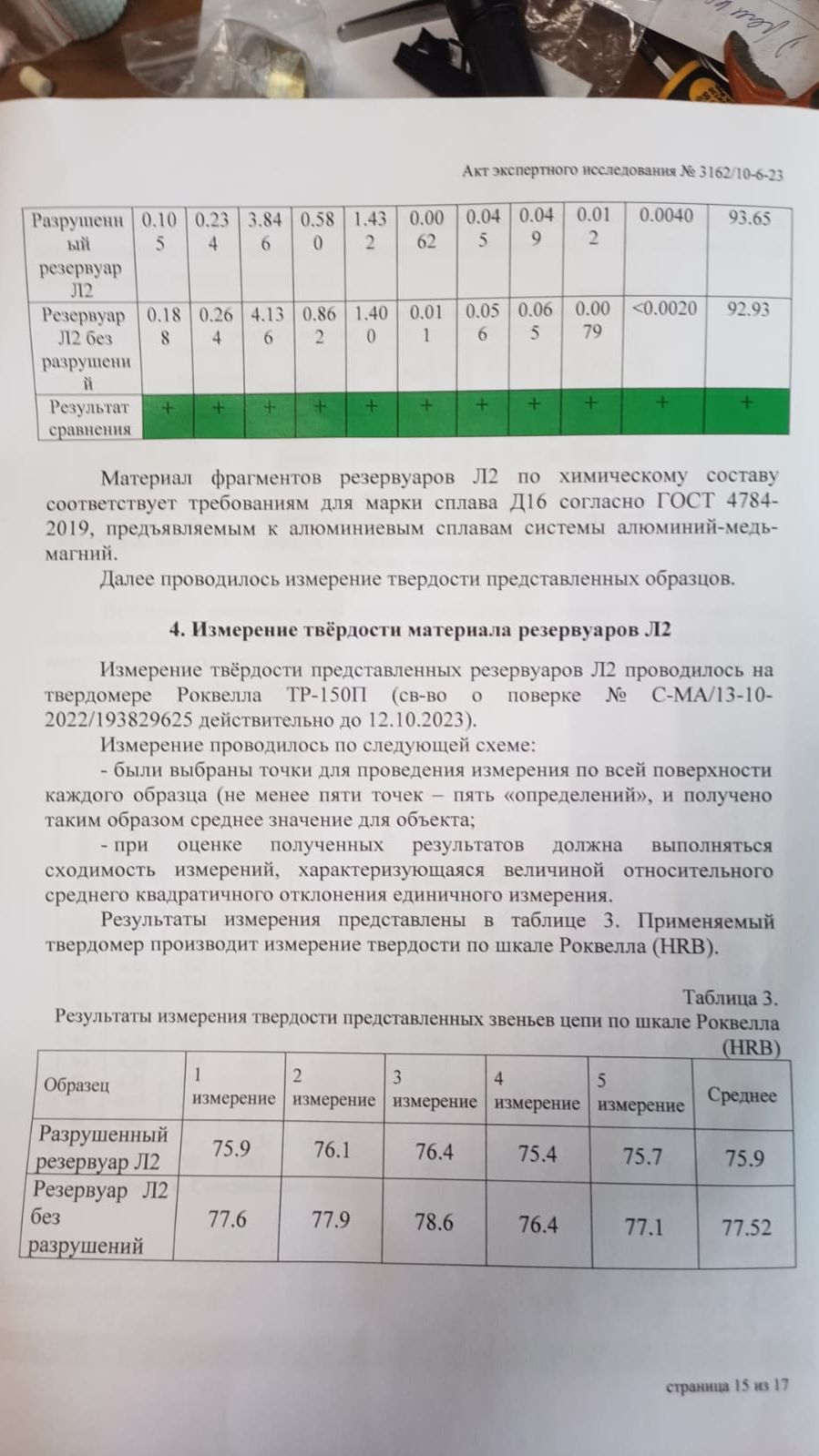

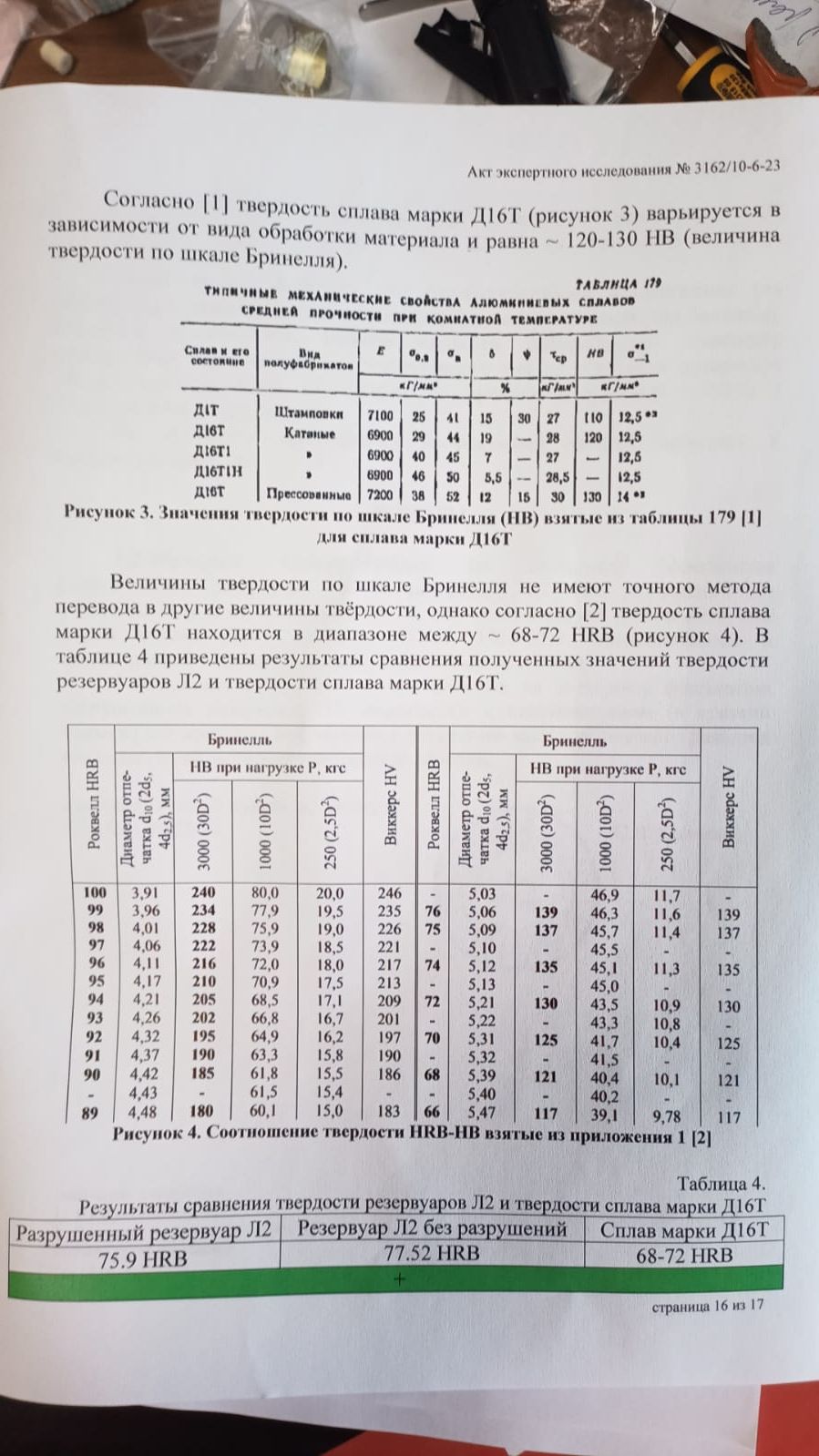

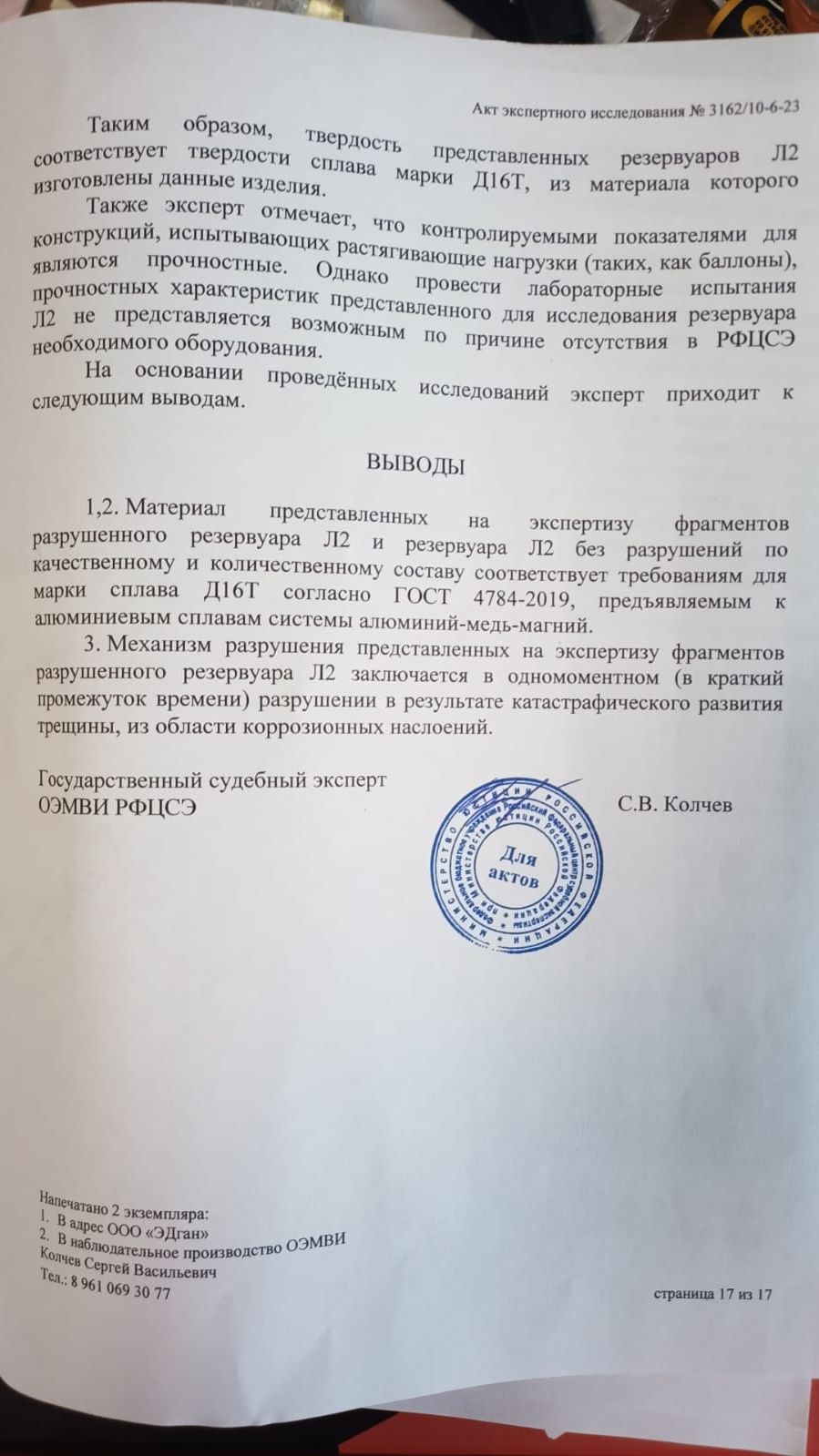

- Expert failed to find some production or metal fails which could lead to the explousure. Conclusion – the material, processing and manufacturing is OK.

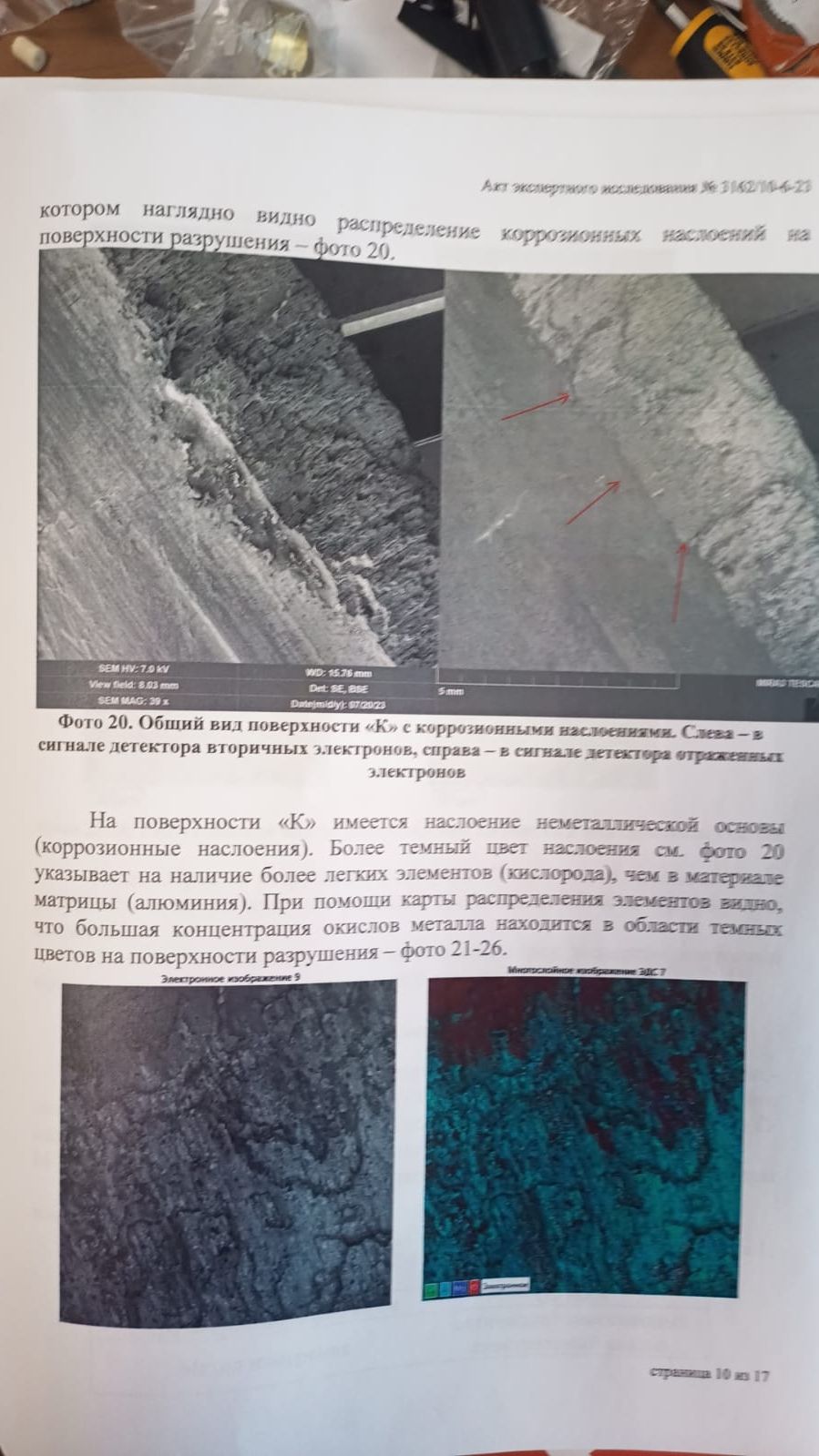

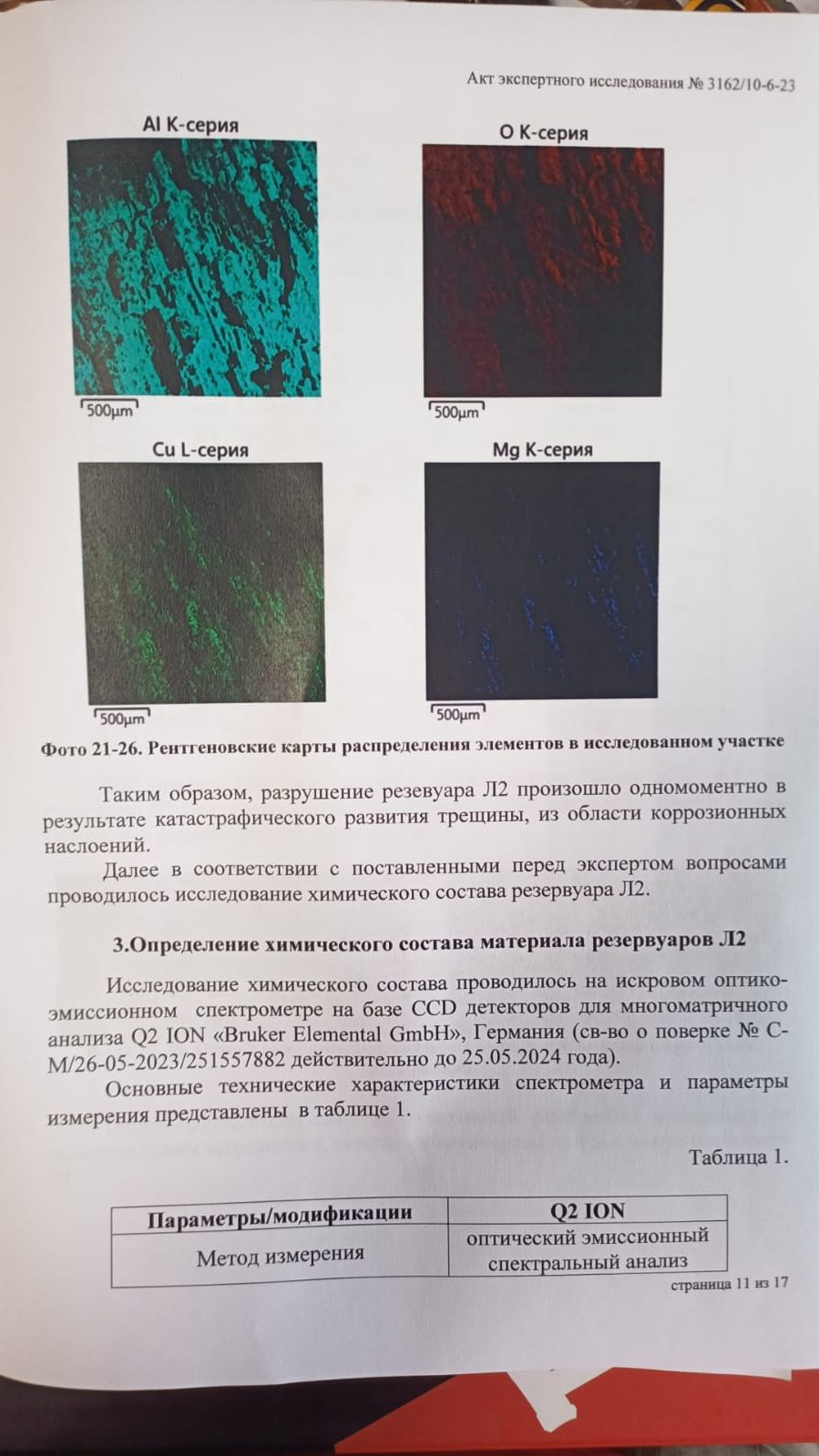

- Based on the examine expert found out that there are much remains of the oxygen in the area of corrosion.

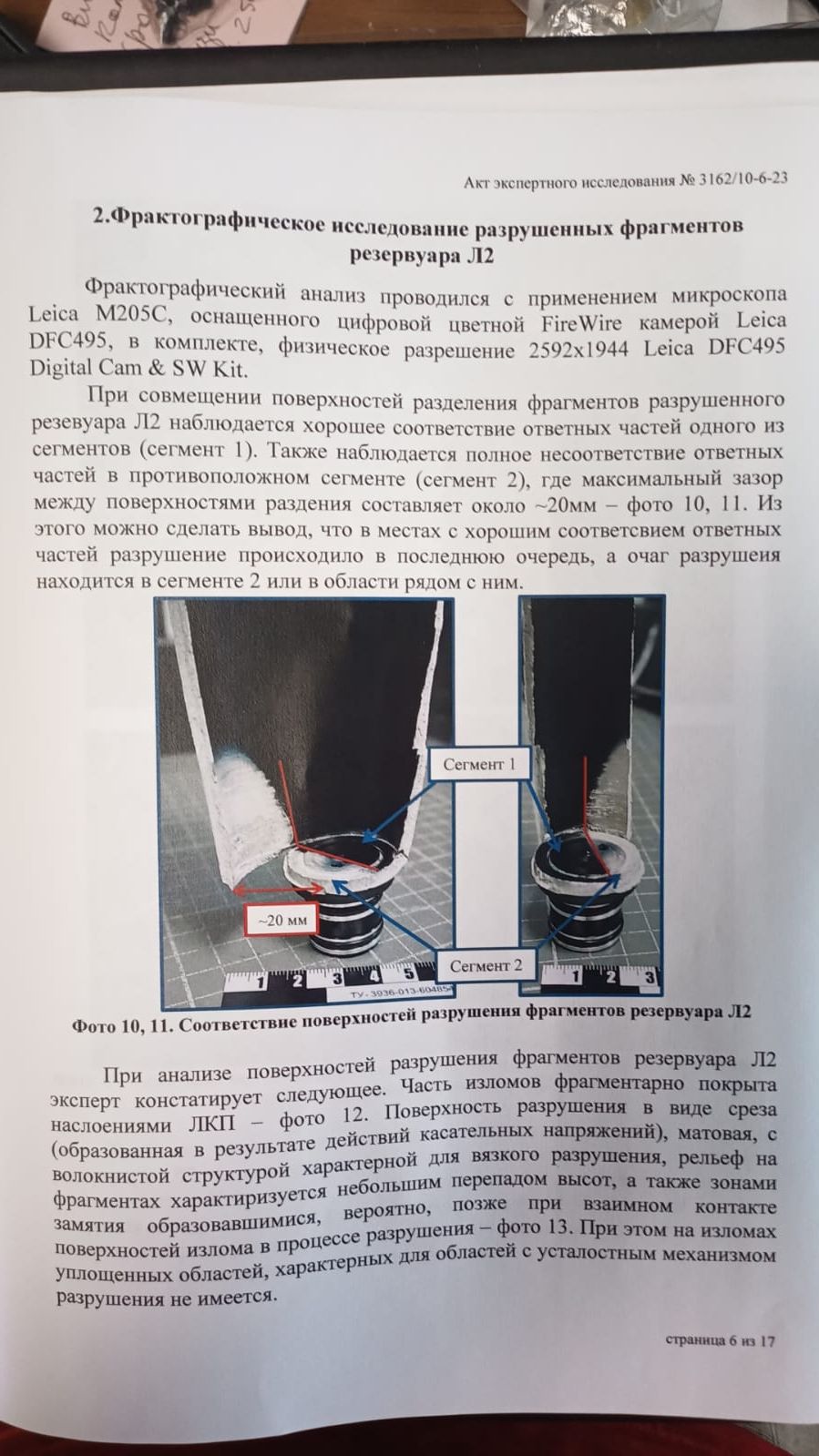

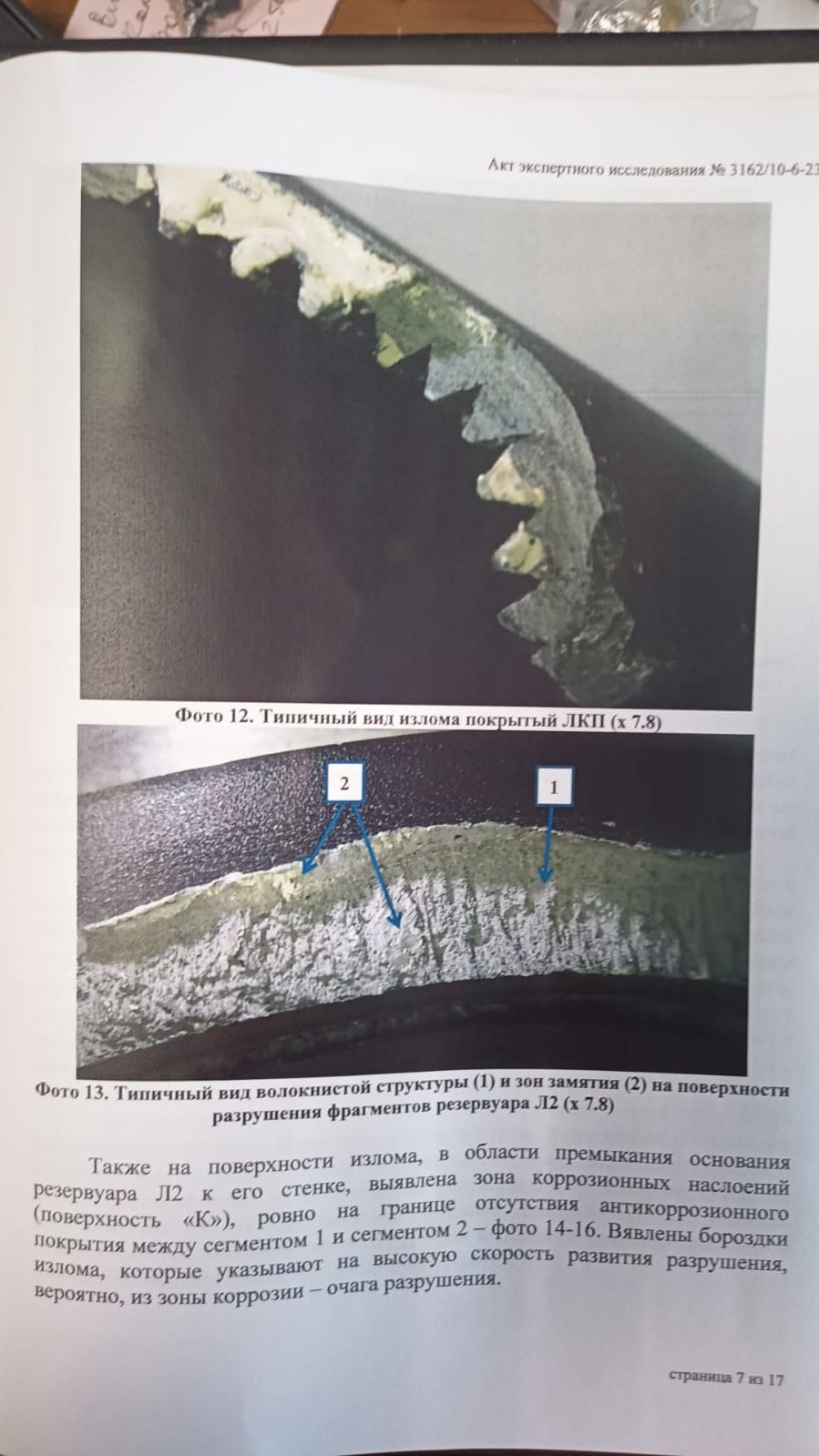

- The destruction started from the corrosion spot.

- The material of both reservoirs, the remains and the test one was tested to meet the standard according to the chemical proportion. It is D16T, as it should be.

Unfortunately, the moisture with some addings (like oil and so on) in the conditions of the high pressure can be very aggressive to the alum alloy.

That is why I, personally, avoid using undried air and use ONLY air from the tanks, filled at the fire department or dive centers, who use air for breathing.

My recommendation to those who has no possibility to use dry air and have to use small compressors or hand pumps – use the best dryer you can find and make the check-out of the inside surface of the reservoirs on the constant base.

From my side, as the manufacturer, I cannot see any mistakes, which was confirmed by this expertise and with my light heart keep going on making the guns using all necessary measures to make them as safe as possible.

With the best regards

Ed