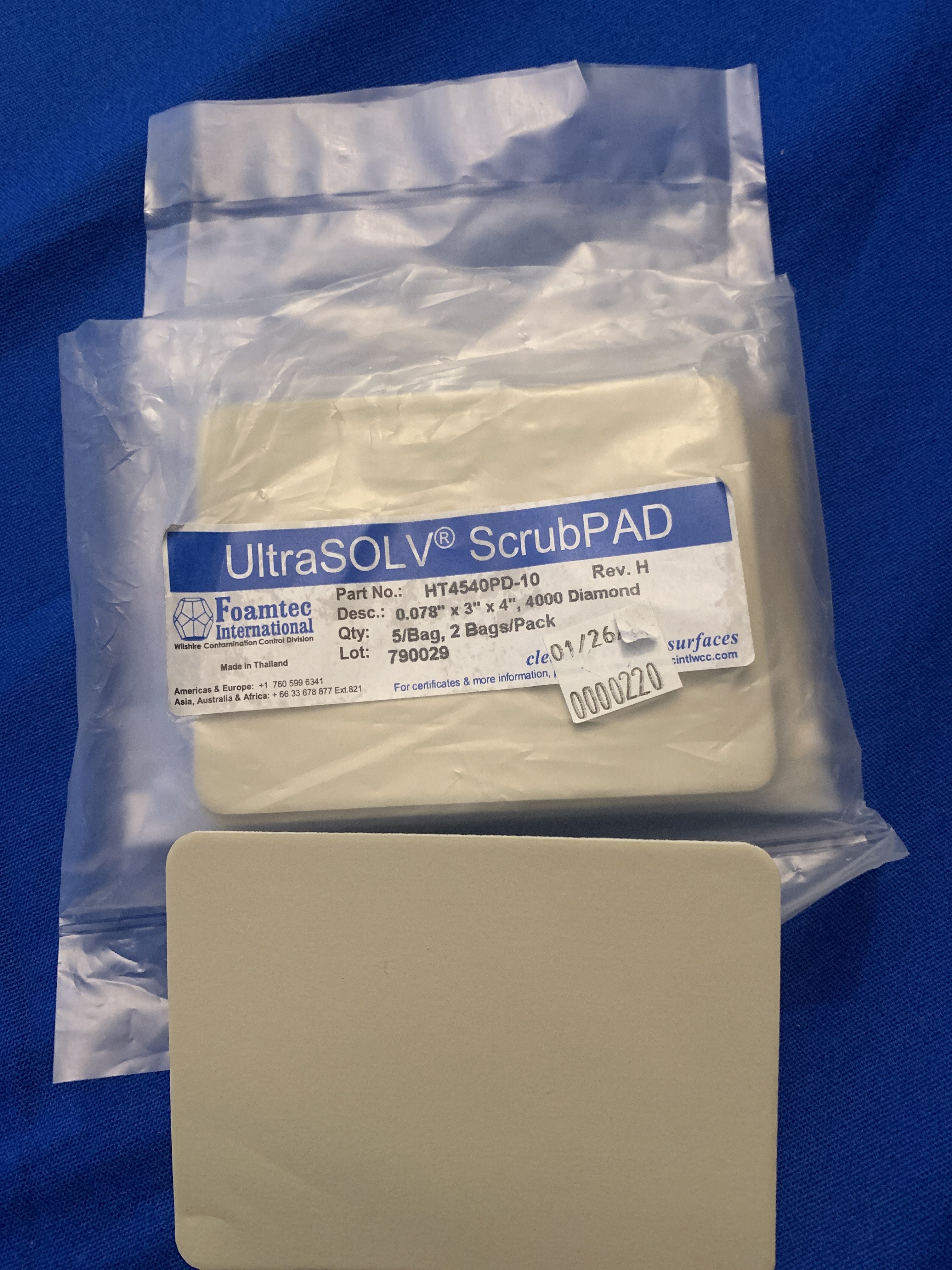

would it be safe to polish an airgun barrel with this? we use this in ultra deep vacuum chambers typically below 10(-9)Torr,(the -9 is supposed to be an exponent).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

barrel polishing..

- Thread starter daddypaddy

- Start date

you mean like cutting a patch size piece ? what kind of material is the backing ?would it be safe to polish an airgun barrel with this? we use this in ultra deep vacuum chambers typically below 10(-9)Torr,(the -9 is supposed to be an exponent).

View attachment 447247

Upvote 0

it’s a flexible foamy material that i can cut with children’s safety scissors. the pad and backing is is probably 1mm thick total. it’s for a clean room environment so it leaves almost no particulates behind when using it. we use it to clean and polish very flat steel surfaces that need to stay very flat.

Upvote 0

i’m imagining it would be an ideal material to use because it doesn’t leave any abrasive powder behind like other abrasive sheets/compounds after being used. i’m still new to airgun maintenance and tuning so i like to be sure and careful about every move i make.

Upvote 0

If the 4000 is the grit, it's not going to do much to even a soft airgun barrel....of course additive effects may eventually get you somewhere.

Upvote 0

I use 400 grit clover (new barrel after basic cleaning patch) on a patch/jag ....... so this is 10x finer.would it be safe to polish an airgun barrel with this? we use this in ultra deep vacuum chambers typically below 10(-9)Torr,(the -9 is supposed to be an exponent).

View attachment 447247

The (400) clover only needs to be used 1 time to smooth out any aberrations in the barrel. Maybe 20 strokes is all that's needed.

I'm not sure how many barrel strokes would be needed to properly dress it with a 4000 grit patch?

After I use clover, I clean out the clover and wax it. When accuracy drops off re-clean the barrel with something like JB non-embedding paste on a jag or Goo Gone on a patch pulled through with weed wacker line .............. then re-wax.

Upvote 0

If it's made for high vacuum environments, I suspect it's completely and utterly safe for your airgun. It's probably not going to polish sh*t*, but it won't hurt anything.

GsT

* to do any meaningful polishing you need to start with a more course abrasive. Or be prepared to make 10,000 strokes...

GsT

* to do any meaningful polishing you need to start with a more course abrasive. Or be prepared to make 10,000 strokes...

Upvote 0

The popular J-B bore compound is about 1000 grit, and quickly breaks down into smaller particles. For the typical new barrel (to the extent there is such a thing), J-B is what I regard as the finest abrasive that makes sense to use.

Many barrels will benefit from something coarser but if you’re new to the practice, I think J-B or something similar is a reasonable place to start to get acquainted.

Many barrels will benefit from something coarser but if you’re new to the practice, I think J-B or something similar is a reasonable place to start to get acquainted.

Upvote 0

I've seen barrels that I think would benefit from valve-lapping compound... (that's (mostly) a joke folks, please don't use valve lapping compound.)The popular J-B bore compound is about 1000 grit, and quickly breaks down into smaller particles. For the typical new barrel (to the extent there is such a thing), J-B is what I regard as the finest abrasive that makes sense to use.

Many barrels will benefit from something coarser but if you’re new to the practice, I think J-B or something similar is a reasonable place to start to get acquainted.

GsT

Upvote 0

lol. it’s a notos barrel and it’s already good as is but i feel like i can make it better.. i can’t stop thinking everything can be made better. haha is that ocd?If it's made for high vacuum environments, I suspect it's completely and utterly safe for your airgun. It's probably not going to polish sh*t*, but it won't hurt anything.

GsT

* to do any meaningful polishing you need to start with a more course abrasive. Or be prepared to make 10,000 strokes...

precisely why i’m looking at this diamond 4000 grit. i know it can clean edges without too much material being removed. i’m afraid i’d end up removing too much metal with anything more course. this would be my first time doing this. the barrel itself is already good but i feel it could be better if it was mirror clean throughout.The popular J-B bore compound is about 1000 grit, and quickly breaks down into smaller particles. For the typical new barrel (to the extent there is such a thing), J-B is what I regard as the finest abrasive that makes sense to use.

Many barrels will benefit from something coarser but if you’re new to the practice, I think J-B or something similar is a reasonable place to start to get acquainted.

Last edited:

Upvote 0

i’m assuming the rifling is smooth out of factory but i know that is nothing but hoping for the best.

Upvote 0

too much is relative .. 4000 will basically do nothing, you need to start with 400-600 to cut coarsness out of most gun parts/barrels at a reasonable pace .. then of coarse you can finish with something fine, anything over 1000 is kindof a waste of time, we're not dealing with match grade lab equipment parts here ... that material you have may or may not be suitable as an application medium though, depending on how well it can be utilized ..

Upvote 0

you have a pointtoo much is relative .. 4000 will basically do nothing, you need to start with 400-600 to cut coarsness out of most gun parts/barrels at a reasonable pace .. then of coarse you can finish with something fine, anything over 1000 is kindof a waste of time, we're not dealing with match grade lab equipment parts here ... that material you have may or may not be suitable as an application medium though, depending on how well it can be utilized ..

Upvote 0

There is nothing new under the sun, papers, foam, sheets, swabs, poured slugs, nothing new.

History shows a mid-grit lapping compound on a tight fitting patch pulled through the bore does more in less time and does not unnecessarily round rifling.

History shows a mid-grit lapping compound on a tight fitting patch pulled through the bore does more in less time and does not unnecessarily round rifling.

Upvote 0

When polishing in a bore, for an even pressure running all the way around the bore as well as keeping lengthwise evenness, I use 3M abrasive sheets and long cotton bore mops. Choosing the appropriate grit needed based on the initial condition of the bore, a measured piece gets wrapped twice around a cotton bore mop wetted with oil and stroked through as necessary using a cleaning rod with ball bearing handle to follow the twist rate. The micro fine grits will polish to an even, mirror finish far better than I've seen with JB Bore Brite.

Here's a link to the multi-grit packs I buy:

Here's a link to the multi-grit packs I buy:

Upvote 0

The 3M sheets are the WTG for simple/effective barrel polishing. I've used diamond lapping pastes on a mop, which also works, but is more of a mess.

Upvote 0

Be sure to use a rod that freely rotates to follow the spiral of the rifling. The goal is to have the compressible material take on the profile of the bore and scrub everything, especially the inside corners of the rifling where lead is particularly prone to abrading and sticking.

Upvote 0

The intention is to remove miniscule amounts of metal - think of it as the undesirable debris left from any machining operation. To that end, you use abrasives which are so mild that actual, destructive, damage is pretty much out of the question.Isn't there a risk of smoothing the rifling sharp edges?

GsT

Upvote 0