Errors like that are pretty common, unfortunately. I suppose contacting the seller might resolve it. One fairly common translation error I see on PCP fittings is stating they are made of copper when often it is obviously made of brass.

On this part, since the holes are drilled all the way through, with no step inside for a sealing O-Ring or nylon washer, the only way you could seal the connection would be with a Dowty washer which might not work on the hole on the flat hex side, and / or Teflon tape. Not a fan of Teflon tape other than as a last resort. I am going to pass on trying this part.

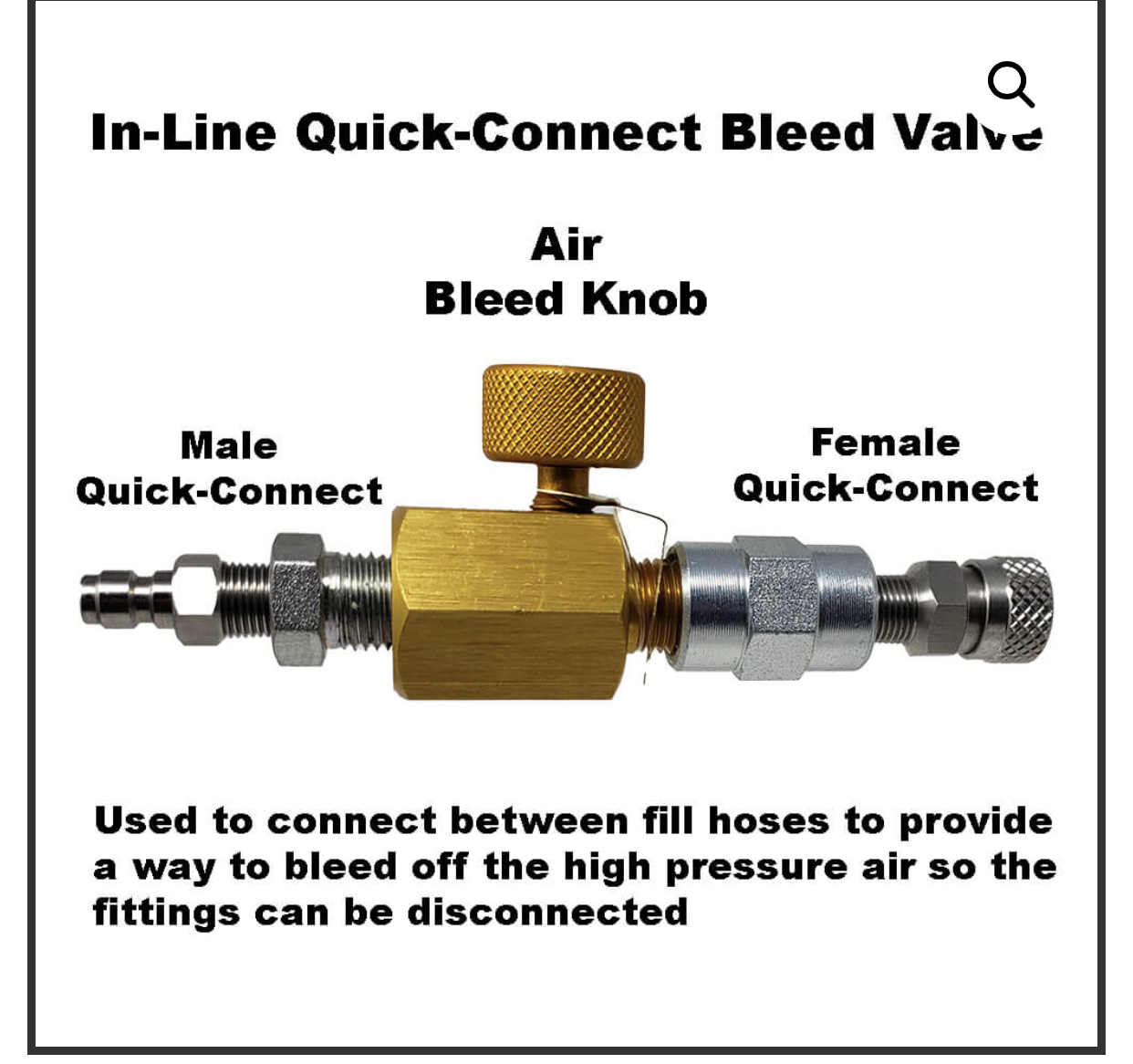

I think what I am going to do for my solution with the best chance of success at the lowest cost unless someone posts a link to the parts in eaglebeak's post for less money, is going to be buying a complete SCBA fill station assembly, remove the SCBA side connector nozzle which threads off the main body, and plug that hole with a short, threaded steel bolt or plug of the same thread size (1/4" NPT) with a cleaned up tip for a good seal on the synthetic washer inside there. If needed I can convert it back to an SCBA fill station in a few seconds. This solution will give me a spare SCBA fill station if if I ever need it, a larger diameter pressure gauge right next to the rifle when filling guns with tiny and / or inaccurate gauges on them, the needed bleed valve plus an extra length of micro bore hose to boot. I can get a complete SCBA fill station for under $40 delivered from Aliexpress. The cost of all the parts needed to build a bleed valve without a gauge is over that amount.