You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone try out the AirMaks Krait X?

- Thread starter Maizen

- Start date

- Status

- Not open for further replies.

The AirMaks Facebook group is also working on the same issue. After sitting for 2wks my reg is showing 130bar, hopefully will be able to run some strings today, currently have a Prophet2 reg on order to double reg it and possibly still maintain a 300b fill.

Upvote 0

400-500 CC Bottle Regulator

Huma-Air external pressure regulator for rifles with a 400 or 500 CC pressure bottle on the front side of the rifle. Consistency is key!

Upvote 0

That’s what I put on mine.

400-500 CC Bottle Regulator

Huma-Air external pressure regulator for rifles with a 400 or 500 CC pressure bottle on the front side of the rifle. Consistency is key!www.huma-air.com

Upvote 0

That is a better looking solution for sure, but about 100 galactic credits more than my solution. Rather than having you go back through the pages of this thread, here are the links that I provided on page 4

400-500 CC Bottle Regulator

Huma-Air external pressure regulator for rifles with a 400 or 500 CC pressure bottle on the front side of the rifle. Consistency is key!www.huma-air.com

REG: https://www.ebay.com/itm/203756174860 (currently out of stock, but a good example of what to look for)

Adapter: https://amzn.to/3UoIDbI

I might scoop up one of those Humas to put on something... tripled reg'd FX Maverick??? Haha! Definitely good for the parts bin at the very least

Upvote 0

280bar fill, RTI reg set at 149b, Krait reg at 125b

(The thread adapter is longer than necessary, will be shortened soon.) Still raining, unable to run it over a Chrono...

(The thread adapter is longer than necessary, will be shortened soon.) Still raining, unable to run it over a Chrono...

Upvote 0

Nice, dude! Looks like you bought the 7 dollar amazon adapter I linked! If you used my link I probably earned about 7 cents! TIGHT!280bar fill, RTI reg set at 149b, Krait reg at 125b

(The thread adapter is longer than necessary, will be shortened soon.) Still raining, unable to run it over a Chrono...

What I did on my Airforce guns with that adapter was I drilled out the pin depressor and then removed the pin from my reg. This added a few CC's of plenum volume. I think I used about a 3/8" bit to do it (piloted with 1/8"), just be careful you don't nick up the sealing surface that the reg orings seal against if you do it.

Upvote 0

Just remember to leave enough threads. Different pitches and types require a certain amount when dealing with 4k psi. You don’t want to launch a missile.280bar fill, RTI reg set at 149b, Krait reg at 125b

(The thread adapter is longer than necessary, will be shortened soon.) Still raining, unable to run it over a Chrono...

View attachment 307521

Upvote 0

We will be installing the V3 reg in the Krait tomorrow.

Standby for an update on whether it fixes the problematic creeping reg pressure and dwindling velocities. Winter is not ideal for testing, but we'll do the best we can.

If it still sucks, double regging the system will almost certainly fix it, so we do have an ace up our sleeve.

Standby for an update on whether it fixes the problematic creeping reg pressure and dwindling velocities. Winter is not ideal for testing, but we'll do the best we can.

If it still sucks, double regging the system will almost certainly fix it, so we do have an ace up our sleeve.

Upvote 0

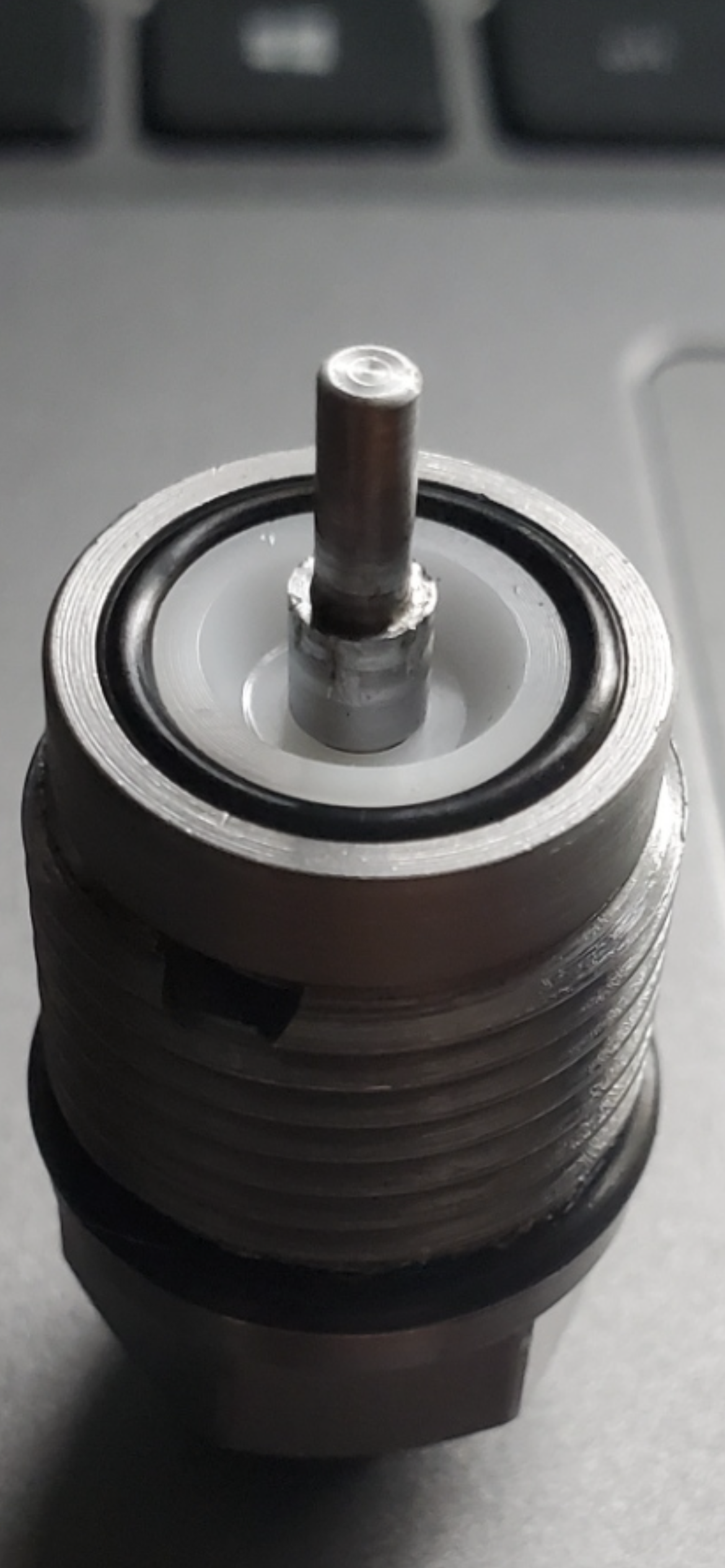

AirShootist sent me a pic of the latest reg they sent him. The first pic is of my V2 reg. The second pic is his V3. If you look at the hard seating surface, you’ll see they put an additional seat that appears to be machined nicely. It’s also beyond the original seat that looks like a rat chewed on it because they grab it there to machine it.

Upvote 0

Waiting for a machinist with a lathe to get spun up, but planning to get a new steel piece machined so the add-on reg won't need the adapter. Replace the Krait M18x1.5m steel bottle insert with a custom made G1/2 piece. 300bar is a lot of pressure and already have the reg, so will use it to knock the pressure down. If the RTI reg creeps a little then that will still be ok as long as the Krait regulator holds, which it should because it will be under less stress?

Just remember to leave enough threads. Different pitches and types require a certain amount when dealing with 4k psi. You don’t want to launch a missile.

Just remember to leave enough threads. Different pitches and types require a certain amount when dealing with 4k psi. You don’t want to launch a missile.

Upvote 0

Yes and no. A bad reg seat is a bad seat no matter how much pressure it’s under. Just because it isn’t under 4,000psi does not make 2,500psi a joke. 2,000psi is still enough pressure to kill you quick. We get so used to working and playing with HPA that we lose respect for it. Bottom line is if your Krait reg is bad, it will just take it longer to creep under less pressure. Or hopefully the creep will be smaller and not significant. Clean up that Krait reg or have your machinist do it before you put everything back together.

Upvote 0

When I get home from this hunting trip my Double regged Krait will have been sitting for 2 weeks. One of the first things on my list is to fire it over the chronograph. I will post my results. If my first shot is out of what I consider a decent ES, I will request a V3 and redo the reg that’s in the gun on my lathe this time while I wait for their latest offering. I did the reg that’s in the gun at my hunting camp using a drill, 1k, 2k grit sand paper on a blade to try to keep the paper square to my work. Straight hillbilly job but it was holding nicely.

Upvote 0

What are we looking at, I confused ?

The small shoulder, 90° off the centerline, at the base of the pin ?

The surface, in the pictures above that looks like a monkey wrenched on, that's all chewed up ?

If that's the "Seat" surface you are all talking about...no wonder things are leaking !

Seems that that pin needs a couple of flats, or a hex machined into it somewhere. Stop all the mishandling.

Mike

The small shoulder, 90° off the centerline, at the base of the pin ?

The surface, in the pictures above that looks like a monkey wrenched on, that's all chewed up ?

If that's the "Seat" surface you are all talking about...no wonder things are leaking !

Seems that that pin needs a couple of flats, or a hex machined into it somewhere. Stop all the mishandling.

Mike

Upvote 0

Yes. What’s happening with their regs is distortion. You can’t have those clamp marks and not wind up with some distortion on the seating surface. They are trying to bandaid it with the nicely done sleeve. Just have to hope the sleeve is a very snug leak free fit to the pin. Or the reg will still creep. Not because you’re leaking at the seat, but because you’re now leaking along the pin. We will see.

Upvote 0

I never held a V3 in my hand so that might all be one piece. Photos can be deceiving. If it’s all one piece and now they just abuse the one end of it, we should be better off.

Upvote 0

Welp.... we installed the V3 reg. Still creeps. Still gets dwindling velocities. Not as bad as the V2 but this is a pretty weak fix....

We doubled reg'd it and will do some consistency testing later since it's dark out now. I will post another video on my channel showing you the performance of the V3 Reg.

We doubled reg'd it and will do some consistency testing later since it's dark out now. I will post another video on my channel showing you the performance of the V3 Reg.

Upvote 0

I recieved my replacement a couple weeks ago. 18 grainers at 870, no reg creap off the 110b setting and 2.4 sd on the last shot string. Taking lots of notes on whats going on just in case I have to call UA. So far so good.

Upvote 0

Thanks Vet -Yes. What’s happening with their regs is distortion. You can’t have those clamp marks and not wind up with some distortion on the seating surface. They are trying to bandaid it with the nicely done sleeve. Just have to hope the sleeve is a very snug leak free fit to the pin. Or the reg will still creep. Not because you’re leaking at the seat, but because you’re now leaking along the pin. We will see.

Geeze, I surely hope the rest of the gun isn't assembled with that sort of..."care"... !

Am I wrong...but it seems that a simple groove in the end of the pin for a flat blade screwdriver might solve the "eF'ed" up seating surface.

Mike

Upvote 0

- Status

- Not open for further replies.