I know this is an odd question...

I am in the process of ordering parts for my push-button electric forward cocking mechanism for these two pups to go with some new stocks I am working on.

I need to know if the solenoid I am ordering has enough force to pull the hammer back and if the spring return is strong enough to push the pellet probe forward and chamber a pellet. I don't have one of those gauges that people use to measure the weight of the trigger pull but I know some people here do. I was hoping someone who owned one also owns a Cricket or Mutant and would be willing to measure it for me?

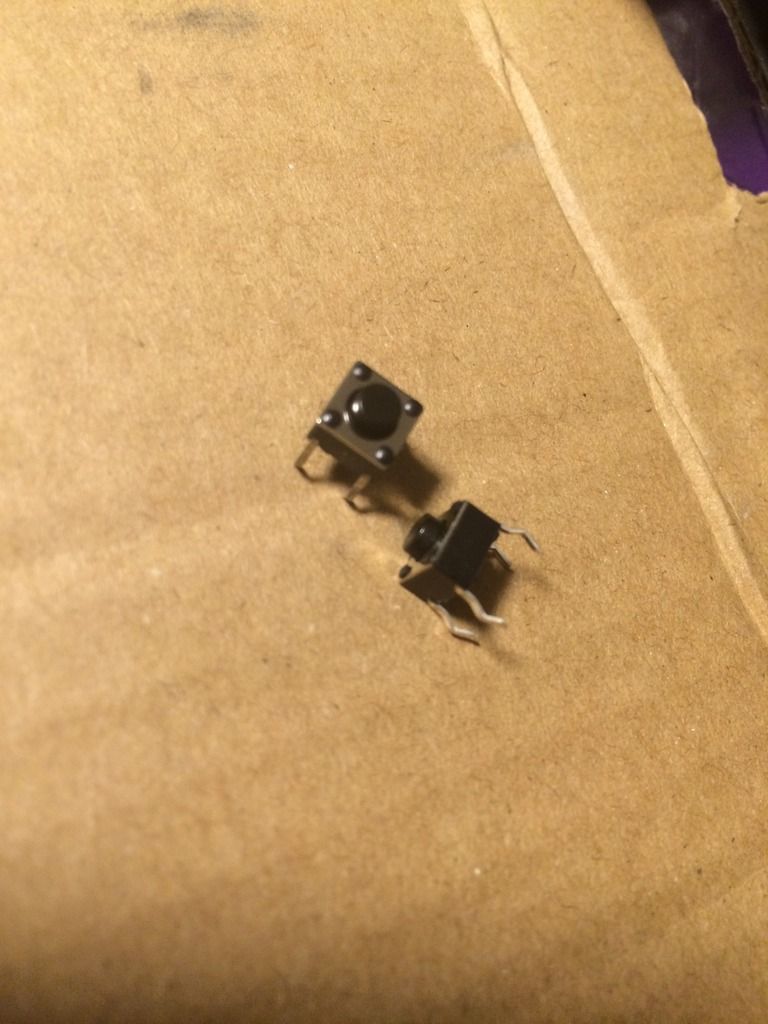

I was going to use a manual lever to create a forward cocking function but I can't resist the idea of using a simple micro-switch butting on the forend...

I am in the process of ordering parts for my push-button electric forward cocking mechanism for these two pups to go with some new stocks I am working on.

I need to know if the solenoid I am ordering has enough force to pull the hammer back and if the spring return is strong enough to push the pellet probe forward and chamber a pellet. I don't have one of those gauges that people use to measure the weight of the trigger pull but I know some people here do. I was hoping someone who owned one also owns a Cricket or Mutant and would be willing to measure it for me?

I was going to use a manual lever to create a forward cocking function but I can't resist the idea of using a simple micro-switch butting on the forend...