I have already ask this once but now I am pretty sure its my TANK,,, Not gauge, So I am asking anyone have the tank leak?

OK let me explain I am on my second set of gages, My first set of gauges that came with the scott tank I tried to put an extra large condom on it, Had to put two of them on, I also did the soap stuff on the gauges, NOTHING, Got to be the gauges ordered a second set of gauges , Cleaned out tank. Lots of snot in it about 1/2 cup , Put set of gauges on aired up to 4500 PSI Leaked down to 3000 in about a week or so, Aired back up soaped up real good at 4500 PSI Negative on the soap

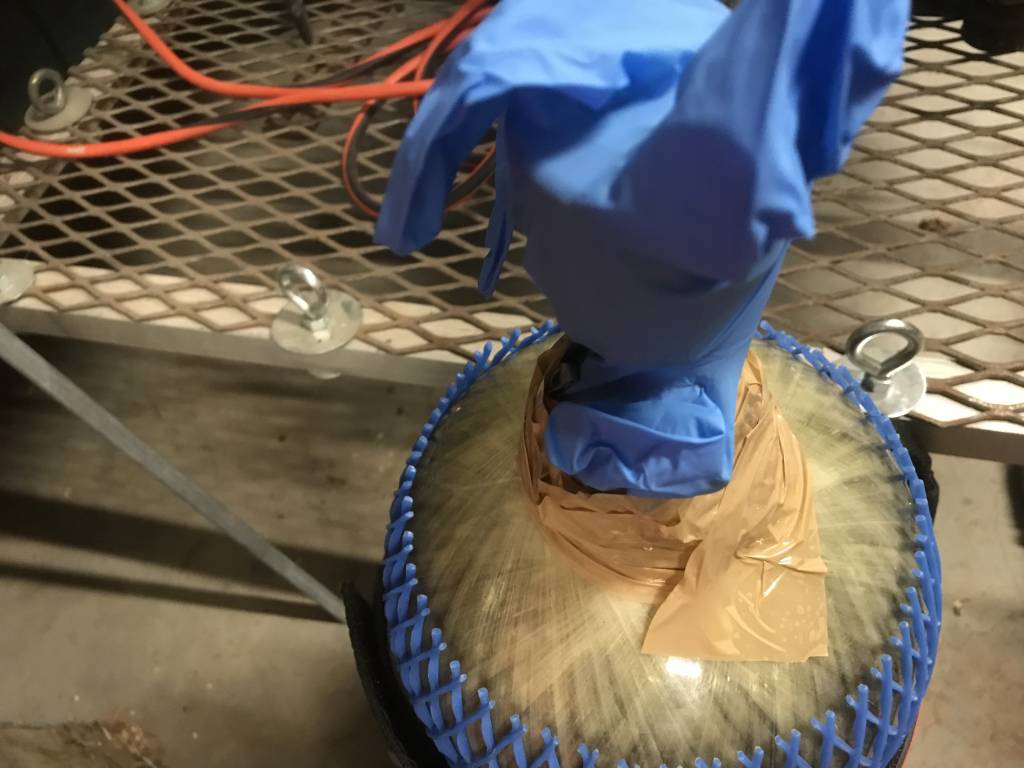

,,, Got a rubber glove

checked it for leaks, Blowed it up a little,,, Placed on bottle taped the snot out of it, ITS SEALED,,,, almost 12 hours NOTHING..... I made sure the glove covered the bottle neck and threading ...What's the THINK TANK say about this one......

OK let me explain I am on my second set of gages, My first set of gauges that came with the scott tank I tried to put an extra large condom on it, Had to put two of them on, I also did the soap stuff on the gauges, NOTHING, Got to be the gauges ordered a second set of gauges , Cleaned out tank. Lots of snot in it about 1/2 cup , Put set of gauges on aired up to 4500 PSI Leaked down to 3000 in about a week or so, Aired back up soaped up real good at 4500 PSI Negative on the soap

,,, Got a rubber glove

checked it for leaks, Blowed it up a little,,, Placed on bottle taped the snot out of it, ITS SEALED,,,, almost 12 hours NOTHING..... I made sure the glove covered the bottle neck and threading ...What's the THINK TANK say about this one......