Asking anybody with Altaros booster experience.....

(and with realization that manufacturer supplied CFM ratings are likely...optimistic)

In regards to shop compressors, it seems pretty standard for them to have an inverse relationship between CFM and regulator pressure (decrease the regulator pressure and the CFMs go up).

With the goals of:

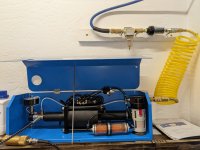

Perhaps not wording that properly...I'll try another way: My shop compressor has a 20gallon tank and is rated to put out 5.3cfm at 90psi. Altaros website specifies 10 bar (145psi) as the max for the first stage/input (shop compressor). Am I going to want to set the regulator on the shop compressor at 90psi so I get that 5.3cfm or will I accomplish my goals of relatively quick fills and minimization of moisture by running the shop compressor with a higher regulator pressure (and therefore lower CFM)?

And a third way to word it: does the Altaros booster like to see (from the shop compressor) higher CFM or higher pressure?

I also have a smaller 6 gallon pancake compressor that is rated for 2.6cfm at 90psi. I understand they can be ran in tandem to get a combined 7.9CFM if I'm unhappy with fill rates from the bigger compressor alone....

(and with realization that manufacturer supplied CFM ratings are likely...optimistic)

In regards to shop compressors, it seems pretty standard for them to have an inverse relationship between CFM and regulator pressure (decrease the regulator pressure and the CFMs go up).

With the goals of:

- relatively quick fills (I used a Shoebox F10 for a few years so I have realistic expectations on fill speeds from boosters)

- and minimizing the production of moisture

Perhaps not wording that properly...I'll try another way: My shop compressor has a 20gallon tank and is rated to put out 5.3cfm at 90psi. Altaros website specifies 10 bar (145psi) as the max for the first stage/input (shop compressor). Am I going to want to set the regulator on the shop compressor at 90psi so I get that 5.3cfm or will I accomplish my goals of relatively quick fills and minimization of moisture by running the shop compressor with a higher regulator pressure (and therefore lower CFM)?

And a third way to word it: does the Altaros booster like to see (from the shop compressor) higher CFM or higher pressure?

I also have a smaller 6 gallon pancake compressor that is rated for 2.6cfm at 90psi. I understand they can be ran in tandem to get a combined 7.9CFM if I'm unhappy with fill rates from the bigger compressor alone....