I topped off both a 30 and 60 minute scba tanks from 4000 psi to 4500 psi this morning, humidity started at 25% and dropped to 15% during the run which lasted 170 minutes.

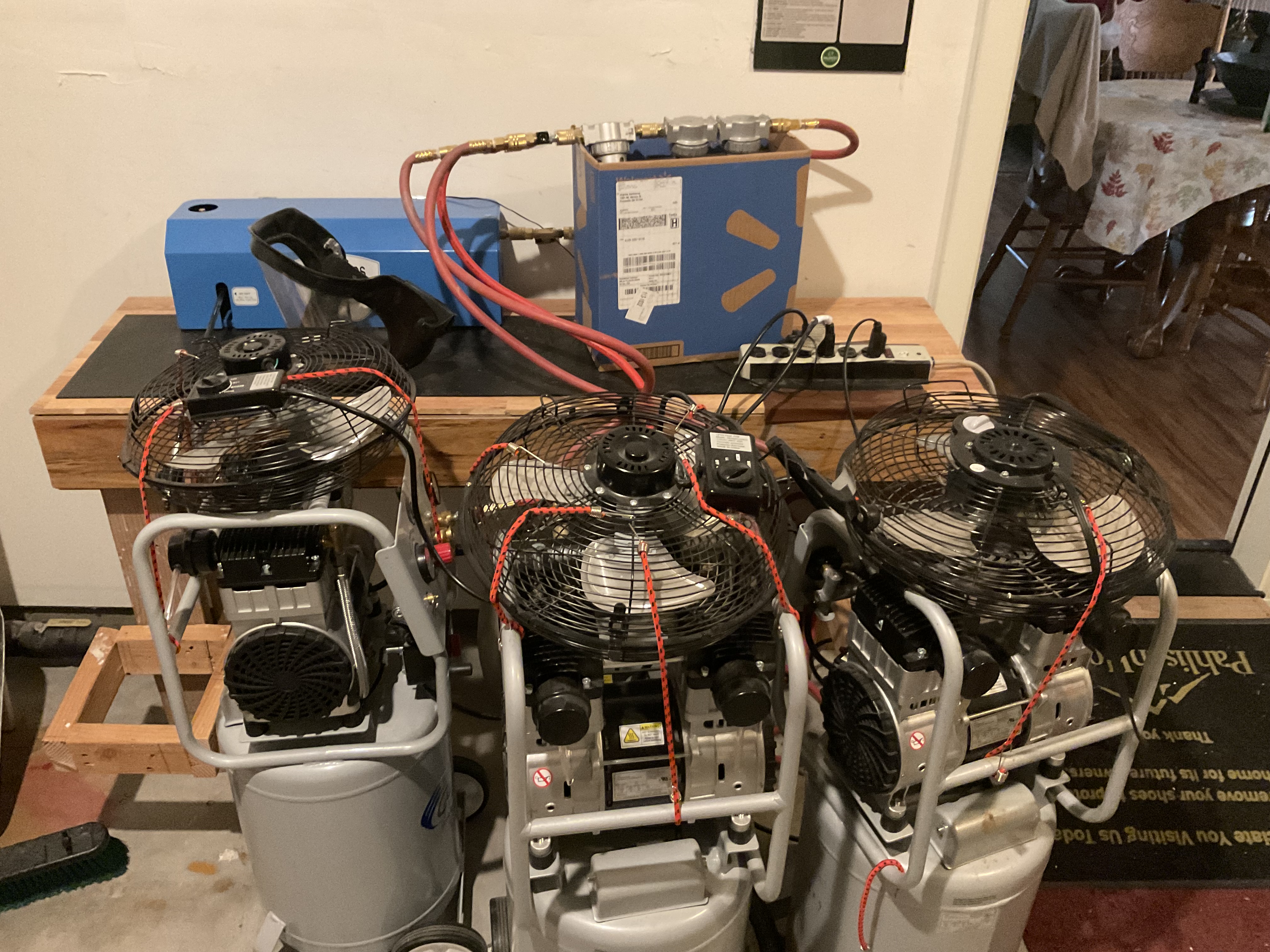

My oldest, 2-2021, California Airtools compressor, CAT #1 had a ratio of 70% rest and 30% run, that compressor is 30 months old and ran the system a few months solo, then later in tandom with compressor #2. Compressor #2 had a 80% rest and 20%run ratio. My newest CAT#3 had a ratio of 85%/15%. The CAT Compressors were slightly warm to the touch, maybe 80-85 degrees after refilling. I think the ratio of CAT#1 was influenced by wear, they are oilerless so they are disposable eventually. Having disclosed its’ age, and the fact that it took the brunt of the wear while I was eventually going to 3 CATs, it is exactly where it should be if new at 70/30.

My three dessicant water filters ended the 170 minute run with #1 saturated and the orange color was then purple, filter #2 had the upper half orange and the lower half purple, filter #3 was still bright orange and needless to say the Altaros filter inside the cabinet was also bright orange.

Regards,

Roachcreek

My oldest, 2-2021, California Airtools compressor, CAT #1 had a ratio of 70% rest and 30% run, that compressor is 30 months old and ran the system a few months solo, then later in tandom with compressor #2. Compressor #2 had a 80% rest and 20%run ratio. My newest CAT#3 had a ratio of 85%/15%. The CAT Compressors were slightly warm to the touch, maybe 80-85 degrees after refilling. I think the ratio of CAT#1 was influenced by wear, they are oilerless so they are disposable eventually. Having disclosed its’ age, and the fact that it took the brunt of the wear while I was eventually going to 3 CATs, it is exactly where it should be if new at 70/30.

My three dessicant water filters ended the 170 minute run with #1 saturated and the orange color was then purple, filter #2 had the upper half orange and the lower half purple, filter #3 was still bright orange and needless to say the Altaros filter inside the cabinet was also bright orange.

Regards,

Roachcreek