I bought this Aero precision ultralight SPR, and milled off the excess left over from the stock rail. One single UTG scope ring weighed more than the new Aero! It seemed to bring a little more weight back into my shoulder. I'm currently searching for a replacement rail for the stock one, and I want one that clamps, not bolts into the receiver. I find it very dangerous that the current rail bolts into the receiver in the same tapped holes as the grub screws that hold the barrel. Any tips on a rail that will fit according to the measurements shown, pls let me know.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Akela picatinny rail modification

- Thread starter Toolmaker

- Start date

Having the rail bolted in poses no danger. The bottom of the bolts holding the rail are still above the top of the set screws holding the barrel. Fully secure the way it is. Not sure what you feel is unsafe about that.

Upvote 0

I understand that and agree with you sir but what I feel unsafe about is steel fasteners in fine threaded aluminum. The rifle in the picture is a replacement rifle the original rifle still wasn't shooting good after I change the O-rings. In order to get to the power selector out, you need to remove that rail to get to the set screw keeping the selector in place. Been a machinist 14 years and I stripped one out. In my defense it squeaked like hell when I originally loosened to two bolts holding the rail on. So it may have ripped them threads as soon as I loosened it. That is VERY common, when steel fasteners are in aluminum threads. Every bolt I put anti seize on before I put them back to stop the corrosion.

Upvote 0

I wouldn't have have chopped it and just take off and mod any one of these to fit the receiver...

Air Force TRI RAIL or a generic one...

https://www.airforceairguns.com/AirForce-Airguns-Tri-Rail-Scope-Base-p/u1039.htm

OR!

https://www.ebay.com/itm/Ohhunt-11mm-Tri-Rail-Dovetail-Rifle-Scope-Riser-Mount-Tactical-Scope-Rail-Mounts/224086051941?hash=item342c91cc65:g:OsAAAOSwVbVfEX9K

Air Force TRI RAIL or a generic one...

https://www.airforceairguns.com/AirForce-Airguns-Tri-Rail-Scope-Base-p/u1039.htm

OR!

https://www.ebay.com/itm/Ohhunt-11mm-Tri-Rail-Dovetail-Rifle-Scope-Riser-Mount-Tactical-Scope-Rail-Mounts/224086051941?hash=item342c91cc65:g:OsAAAOSwVbVfEX9K

Upvote 0

You probably need something like this if it's a Picatinny under that OEM rail... Oh you're a machinist maybe mod the Tri Rail or generic one to mount fit.

Upvote 0

My last resort will be to mill the OEM rail and add the toe clamp, but time is money. That's gonna take a couple hours, and for two hours wage I could have just bought it cheaper. Also, we don't have an anodizer, that's black sharpie on the front of the OEM atm. I'll machine it if I have to, but I don't want those bolts in there too long without antiseize. A chemical reaction takes place, here is a link explaining https://youtu.be/ZAuv7RV7Sz4

Upvote 0

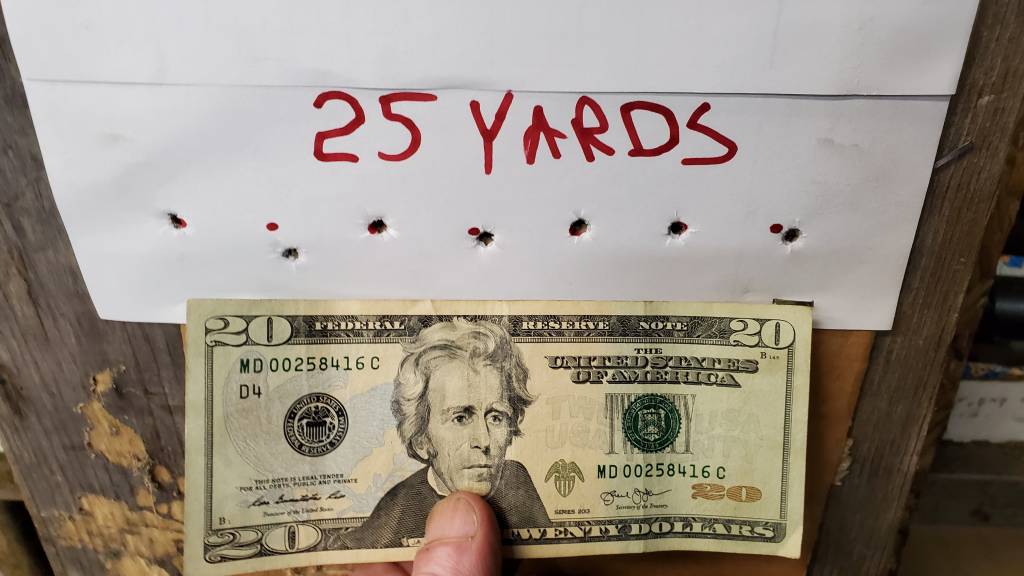

I'm very very happy with the new gun I was sent tho! The bolt works much smoother, and here's a picture of the 25 yard accuracy with Diablo exacts 18.13 gr

I will definitely be purchasing more rifles from Benjamin, the customer service is without a doubt the best I've ever come across so far in life.

I will definitely be purchasing more rifles from Benjamin, the customer service is without a doubt the best I've ever come across so far in life.

Upvote 0

Thank you, I got to admit the second from left I was shaking like a dog pooptin a pine cone. That one was all me, I knew it was bad right from the trigger

Upvote 0

I’m glad they sent you a good one this time. I’m happy with mine so far. My taller rings will be here Monday but I moved my Scope forward a little and then I took the cover that slides up and down on the cheek rest because it’s still smooth underneath. And it made it a quarter inch lower. So now it’s more comfortable and I don’t have to tilt my head way down to the side to see through the scope. But I know what you mean about Steel screws in aluminum. That’s why a lot of jobs we did for the Government called for Heli coil’s to be installed. Much stronger.

Upvote 0

Yep, I've put them in several of my mono block alu. receivers. They are long term life savers! ;<)

Knife

Knife

Upvote 0

I also had to remove the cheek rest to see through the scope comfortably. It's not an issue at all to me, although once I get the proper size riser, I'll be able to put it back on. As for the helicoil, it's the same drilled&threaded holes that the grub screws go in. I'm very reluctant to counterbore it with an end mill sized for the helicoil. I asked my boss his opinion and he agrees 100%. If I were to do that I would need to run a tap down through the grub screws to clean up the top of the thread where the counterbore starts. I reeeeeeealy do not want to have to run a tap back through those aluminum threads while praying I'm in right. IMO a clamp on rail is the easiest and safest solution.

Upvote 0

Antiseize paste  . I use it also for steel screws in aluminum, like scope mounts. Easy does it.

. I use it also for steel screws in aluminum, like scope mounts. Easy does it.

Upvote 0

I wasn’t meaning you should put Heli coil’s In your gun. I was just saying that is why they are used in some applications. As far as I can remember the only thing that made me nervous was tapping titanium with a 440 tap by hand. Or sometimes using small carbide taps. Things would be going fine then all of a sudden TINK And you’re looking at a broken tap Inside a part.

Upvote 0

They have a clamp on riser on eBay. They have a half inch or a 1 inch. I don’t know exactly if that’s what you’re looking for. I tried to get a screenshot of it but I’m not real good at those type of things. But there’s all kinds of options on eBay if you go look at the scope mount section. I was thinking of using one myself but opted for the taller rings instead.

Upvote 0

I also had to remove the cheek rest to see through the scope comfortably. It's not an issue at all to me, although once I get the proper size riser, I'll be able to put it back on. As for the helicoil, it's the same drilled&threaded holes that the grub screws go in. I'm very reluctant to counterbore it with an end mill sized for the helicoil. I asked my boss his opinion and he agrees 100%. If I were to do that I would need to run a tap down through the grub screws to clean up the top of the thread where the counterbore starts. I reeeeeeealy do not want to have to run a tap back through those aluminum threads while praying I'm in right. IMO a clamp on rail is the easiest and safest solution.

I've used clamp on rails and don't care for them myself...

You being a machinist with all the equipment needed, is there room to make new mounting holes for the rail, slightly forward maybe with helicoils..? Could also helicoil the barrel set screws to make it rock solid and able to do 1000 dis-assemblies without stripping. This would add some quality to the Akela for those of us wanting to take apart the gun numerous times for cleaning /etc... I'm a big anti-seize fan, luv the marine anti-seize. With clean properly torqued fasteners anti seize is the way to go for no thread problems ever and correct clamping force.

Upvote 0

I like how the Benjamin looks, but the punchers rail mount seems a lot better. I wonder what prompted them to change it from the Punchers style.

Upvote 0

I stripped my threads in the block due to this .I am now trying to rig something up so I can have the OEM pic rail. At the moment trying to save $.I understand that and agree with you sir but what I feel unsafe about is steel fasteners in fine threaded aluminum. The rifle in the picture is a replacement rifle the original rifle still wasn't shooting good after I change the O-rings. In order to get to the power selector out, you need to remove that rail to get to the set screw keeping the selector in place. Been a machinist 14 years and I stripped one out. In my defense it squeaked like hell when I originally loosened to two bolts holding the rail on. So it may have ripped them threads as soon as I loosened it. That is VERY common, when steel fasteners are in aluminum threads. Every bolt I put anti seize on before I put them back to stop the corrosion.

Upvote 0