Jeeze I get tired of seeing this phrase, "made of Aerospace aluminum".

Have any of you wondered what this phase "really" means ?

It means...NOTHING ! At least nothing that has any credibility as to its strength, that really means anything.

In my approximately 40 years of working in the Aerospace industry, in both the aero (aircraft) portion of the industry and the space part of the industry. I retired out of the "space" portion of the Aerospace industry, I've used, designed to be used, tested and recommended to be used, most all currently available aluminum. Even some custom, very high dollar materials. Along with MANY other materials.

A quick explanation.

Aircraft - In any given aircraft, jet engine planes, that are used in the commercial industry, military industry. Piston engines used in private planes... Both commercial and military, almost the entire gamut of aluminum that the aluminum industry produces, has it's place in aircraft. From the lowly 1100 annealed, to 7075-T6 (or T56), and many "custom"... grades of aluminum, that most never hear of. From the skins, to the honeycomb panels, to the floors, to the stringers, to the rivets. In both jet engine planes to piston engines and their planes, landing gear, most every part that you can think of and many that most don't know about, again, from the super soft, to the custom grades. The pistons in piston engines is much the same as used in some automotive piston materials.

Spacecraft - Pretty much the same things as above in aircraft. The honeycomb panels that make up the "buss" (or body) of most all satellites, soft aluminum ! Aluminum that has very little strength on its own. BUT...assembled the way that it is, a soft aluminum, will end up being very strong after it's "bonded" (glued!) together. The black box's, the bracketry that hold the wiring. Coolant tubes and their mounts. Brackets and hinges that hold the solar arrays and the antennas.

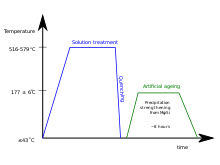

The material heat treatment - Some aluminum is heat treated to make it harder or tougher than it is in its natural state. There's cast, forged and billet versions of aluminum. Forged and billet is much the same production. The various heat treatments (including annealing) will make aluminum more ductile, tougher, malleable.

So, all said, "Aircraft Aluminum" can mean, from, soft window frames or honeycomb core, to landing gear parts that are designed to be both tough, strong.

The next time that you read, "Aircraft aluminum" in the construction materials, there's NO need to be impressed.

Mike

Have any of you wondered what this phase "really" means ?

It means...NOTHING ! At least nothing that has any credibility as to its strength, that really means anything.

In my approximately 40 years of working in the Aerospace industry, in both the aero (aircraft) portion of the industry and the space part of the industry. I retired out of the "space" portion of the Aerospace industry, I've used, designed to be used, tested and recommended to be used, most all currently available aluminum. Even some custom, very high dollar materials. Along with MANY other materials.

A quick explanation.

Aircraft - In any given aircraft, jet engine planes, that are used in the commercial industry, military industry. Piston engines used in private planes... Both commercial and military, almost the entire gamut of aluminum that the aluminum industry produces, has it's place in aircraft. From the lowly 1100 annealed, to 7075-T6 (or T56), and many "custom"... grades of aluminum, that most never hear of. From the skins, to the honeycomb panels, to the floors, to the stringers, to the rivets. In both jet engine planes to piston engines and their planes, landing gear, most every part that you can think of and many that most don't know about, again, from the super soft, to the custom grades. The pistons in piston engines is much the same as used in some automotive piston materials.

Spacecraft - Pretty much the same things as above in aircraft. The honeycomb panels that make up the "buss" (or body) of most all satellites, soft aluminum ! Aluminum that has very little strength on its own. BUT...assembled the way that it is, a soft aluminum, will end up being very strong after it's "bonded" (glued!) together. The black box's, the bracketry that hold the wiring. Coolant tubes and their mounts. Brackets and hinges that hold the solar arrays and the antennas.

The material heat treatment - Some aluminum is heat treated to make it harder or tougher than it is in its natural state. There's cast, forged and billet versions of aluminum. Forged and billet is much the same production. The various heat treatments (including annealing) will make aluminum more ductile, tougher, malleable.

So, all said, "Aircraft Aluminum" can mean, from, soft window frames or honeycomb core, to landing gear parts that are designed to be both tough, strong.

The next time that you read, "Aircraft aluminum" in the construction materials, there's NO need to be impressed.

Mike