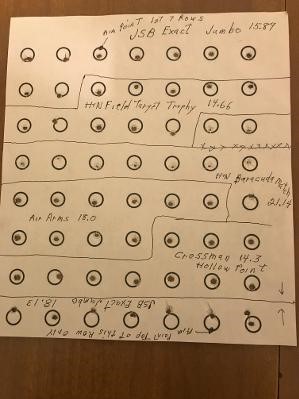

I have had my avenger for several weeks now. I received my pellet order and had time to test the different pellets that I received. I have only tested in the basement at 33 ft. I really cant tell for sure which is best until I get to the club to get some distance shooting. I will try to attach a pic and see what you think.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

air venturi avenger pellet test

- Thread starter miatamama

- Start date

33 feet is pretty much exactly the distance I shoot indoors. It's not the worst and its nice to have "on demand" trigger time. You can definitely sort out the pellets a rifle hates at that distance, and similar tell which ones it loves if you put a mag through a single hole. However, you can't be wobbly or you'll lose your data since you're looking for such a tiny fraction point of impact movement, so I find it good practice too. I'm green with envy for those who can blast away at home at 50 yards on demand....one day....one day....

Upvote 0

I have the Avenger in .25 and it shoots my cast 26g and 34.5g fantastic. They're both close the same skirt diameters as the JSB25.39 & MKII's

Upvote 0

I'll be curious to see your results as you build them up. I've got one coming in that's .177 and one that's .25 -- neither caliber of which I have ever shot before, except .177 in a pistol. I hope you're having fun with your gun, and I can hardly wait to get mine!

Upvote 0

Gonna put my PARD NV008lrf on it. Overkill? Probably. But I like the whole transition from analogue to digital in a big way, whether from movie film to scopes.

Upvote 0

Tell me, is there a practical reason for putting carbon fiber wrapping on the barrel? Does it help with noise, or strengthen it against impact, or keep it from getting scratched? Why did you decide to do that?

Upvote 0

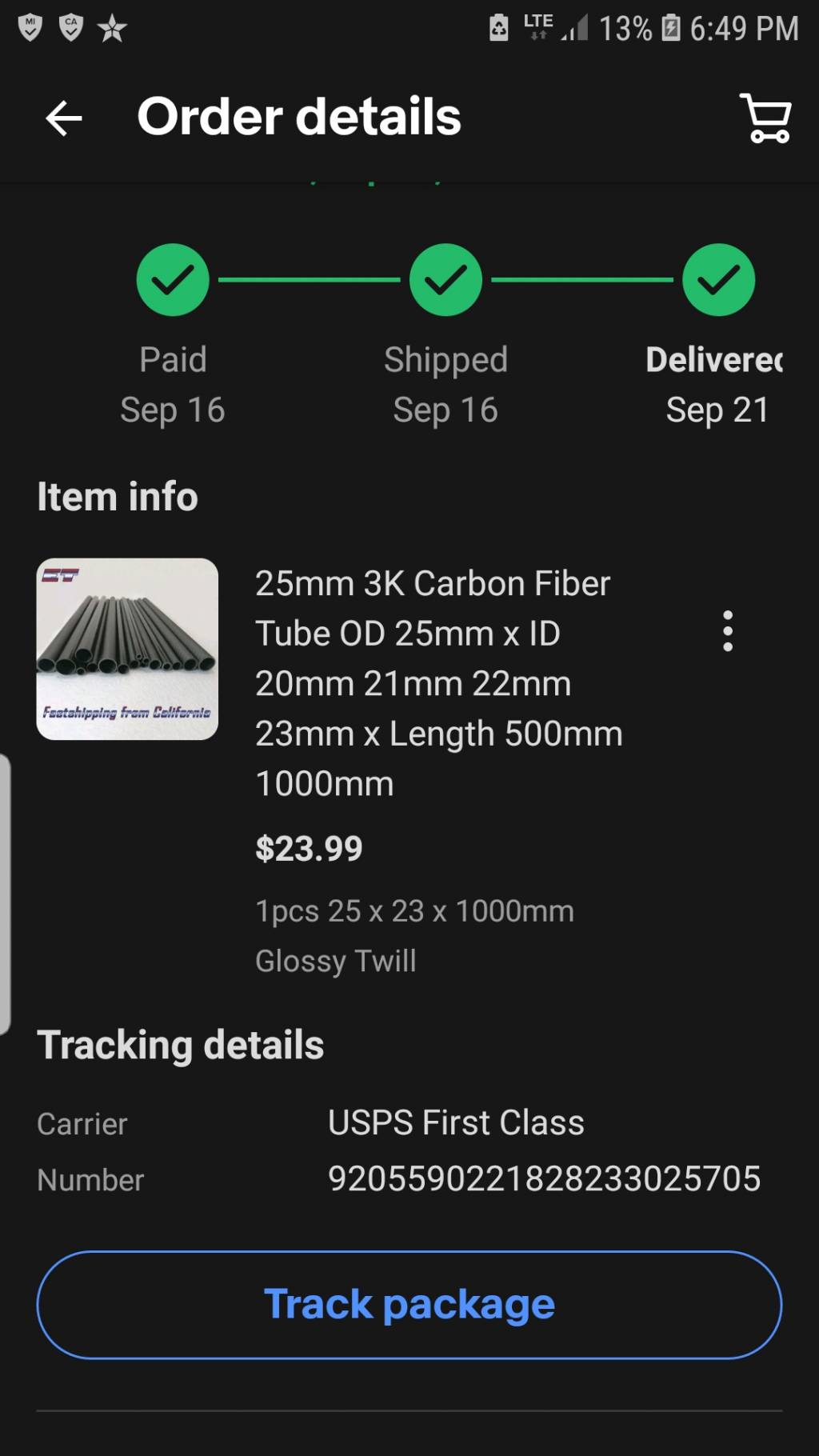

It's not Wrap it's a carbon fiber tube, that I replaced instead of the factory shroud. I put it on because after I put the Donnyfl adapter in. You could see were the it disformed the shroud. Carbon fiber is supposed to be 9 times stronger than steel. It also knocked off some weight, since my scope is heavy and I'm using a fourteen round magazine in .25. Just trying to keep the weight down!

Upvote 0

Uh oh, relevancy alert! I have a couple of DonnyFL's and the adapter, and am going to put myself in a similar predicament, maybe. I don't know anything about this carbon fiber stuff -- where did you get yours and in what size, link would be great!, and did you need some kind of tooling or equipment or whatever to make this work for you? Light is what I love, strong makes sense, and the look is great too. And ... I also have a fairly heavy scope too (PARD). So I may well want to do what you did ...

Upvote 0

You will have to cut it to desired length, sand the cut end on a disc sander to make sure it's 90 degrees even. Drill the hole for the set screw near the breech for the screw. Sand the threads on the adapter down just a little with sandpaper, so you can push it in tight. And use some type of epoxy so it doesn't come out. It's not hard if you take your time, and I cut mine a little longer for sanding. And so I wouldn't have to purchase his new adapter or used the tapered cap on the moderator, and install a bigger one in the future.

Upvote 0

Thanks man, I really appreciate the effort! And I also appreciate the price. Not bad at all, for the value.

Upvote 0

Anytime, if you mod the rifle it would be even better. I drilled the barrel port, washer mod on hammer spring, lighter valve spring. And it's shooting just as well as my impact, before I got rid of it.

Upvote 0

Wow that's really saying something. That's one of the reason I bought the Avenger -- I figured it was already so popular and well-publicized that there would be oodles of info on mods, accessory parts being made, etc., that what started out as a $300 rifle would not remain so for long ... so even if it was lacking, it could be improved, and if good, maybe it could be great.

Anything gun-smithy is beyond me if only because I don't have the tools, but another reason I got the Avenger is I thought it would be a relatively cheap way to learn. It's one thing to screw up something worth $1500 or $2300, but another to screw up a $300 gun. Learning does sound cool, and I'd rather learn at low risk.

What's the washer mod, by the way? Reminds me of something I read about putting washers in with the Prod -- the bstaley mod.

Anything gun-smithy is beyond me if only because I don't have the tools, but another reason I got the Avenger is I thought it would be a relatively cheap way to learn. It's one thing to screw up something worth $1500 or $2300, but another to screw up a $300 gun. Learning does sound cool, and I'd rather learn at low risk.

What's the washer mod, by the way? Reminds me of something I read about putting washers in with the Prod -- the bstaley mod.

Upvote 0

The carbon fiber tube for the Avenger is 25mm outside diameter 23mm inside diameter x 1000mm. The washer mod is the same as on the Nova Liberty. It just shims the spring. I have my hammer spring backed all the way off. And with that I'm pushing Nsa Slugs 26.5gr. @ 875. I'm trying to tune the rifle for heavier slugs. I might be done with pellets, if I can get this rifle tuned for heavier slugs hole in hole @ 50yrds!

Upvote 0