This morning my Air Venturi 4500 psi compressor would not pressurize. I cannot find any leaks. Its about 4 months old, I use it about once a week to top off a 3000lb scuba bottle. I plugged the end of the hose, no pressure build up. A tiny bit of pressure was released from the check valve. I could find no leaks using soapy water. I hooked up a full bottle to attempt to put more pressure in it, still could find no leaks and the pressure held on the bottle. My guess is probably a bad o ring on a piston, where do I start, other than calling Air Venturi.

- The AGN App is ready! Search "Airgun Nation" in your App store. To compliment this new tech we've assigned the "Threads" Feed & "Dark" Mode. To revert back click HERE.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Air Venturi 4500 psi compressor won't pressurize

- Thread starter rickn

- Start date

Sorry to hear this. So it won't build any pressure at all? Usually when they go south they will still build pressure but maybe not enough. Since you've had it for a while I feel pretty confident that you have the bleed off knob snugged tight. Does it sound like everything is about normal, not any new sounds or lack of the correct sound?

When you say a little bit of air was released from the check valve, are you referring to maybe the burst disk fitting just above the bleed off valve handle? There's not a check valve that should emit any air. These rupture disk have been known to fail prematurely and that would definitely prevent it from compressing and a leak there could be masked by the motor fan blowing that way. Usually if the high pressure seals go bad then it'll still compress and possibly be sending blackish crud to the filter housing and it would be recognizable when you bleed the pressure off with the bleed valve. Be glad to help if I can.

jking

When you say a little bit of air was released from the check valve, are you referring to maybe the burst disk fitting just above the bleed off valve handle? There's not a check valve that should emit any air. These rupture disk have been known to fail prematurely and that would definitely prevent it from compressing and a leak there could be masked by the motor fan blowing that way. Usually if the high pressure seals go bad then it'll still compress and possibly be sending blackish crud to the filter housing and it would be recognizable when you bleed the pressure off with the bleed valve. Be glad to help if I can.

jking

Upvote 0

I forgot to mention that it did expel some black crud, like oil? The rupture disc is ok. It sounds just like it normally sounds. When I said check valve I meant the air bleed screw. When I turned the unit off, a very small amount of pressure came out of the bleed screw, black oil on floor. Thanks Rick

Upvote 0

That does sound lke the high pressure seals then. It's pretty easy to inspect and replace them or you can return it to AirVenturi since it's still under warranty. Getting authorized to send it back and packing it assuming you still have the box is a real pita. Doesn't really seem to matter about the hours although you shouldn't have any issue with no more run time then what it sounds like you have on your unit.

Here's a thread about my AV not compressing as well as it should. If you just want to pull the high pressure side upper off it's about a 15min job, less once you've done it a couple of times.

https://www.airgunnation.com/topic/air-venturi-or-hatsan-compressor-question/?referrer=1

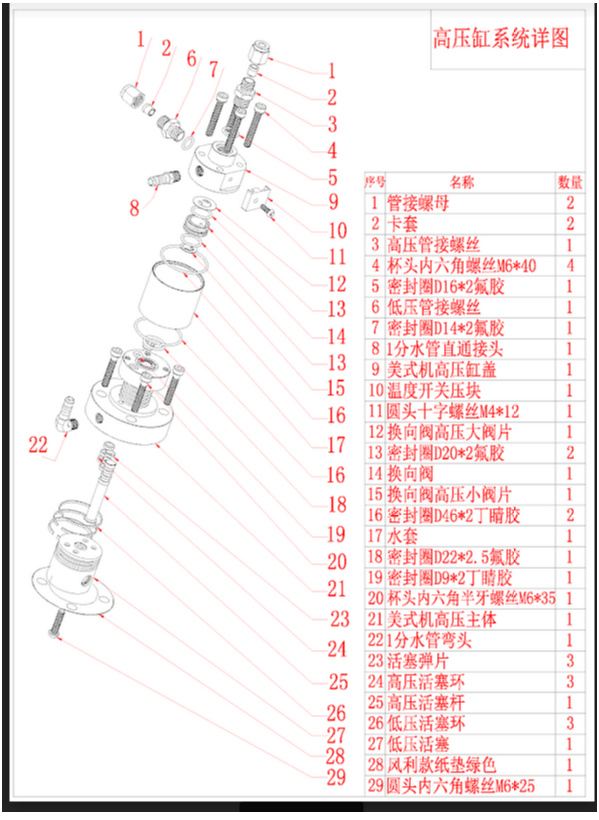

Here's a schematics of the HP side. If you just want to pull the minimum parts to inspect the high pressure seals just loosen and remove the SS lines, the coolant lines and the temp probe and them remove the four hex screw ((#20's) and carefully lift the whole HP cylinder off as one piece. This is probably the easiest way to get to the seals without dismantling any more than necessary. It would be a good start anyway.

Here's a thread about my AV not compressing as well as it should. If you just want to pull the high pressure side upper off it's about a 15min job, less once you've done it a couple of times.

https://www.airgunnation.com/topic/air-venturi-or-hatsan-compressor-question/?referrer=1

Here's a schematics of the HP side. If you just want to pull the minimum parts to inspect the high pressure seals just loosen and remove the SS lines, the coolant lines and the temp probe and them remove the four hex screw ((#20's) and carefully lift the whole HP cylinder off as one piece. This is probably the easiest way to get to the seals without dismantling any more than necessary. It would be a good start anyway.

Upvote 0

The compressor came with some seals and gaskets, I am leaning towards trying to fix it. I will still call air venturi in the morning see how they handle things. Probably won't be able to work on it for a few days, I have to take a quick detour by the hospital Tuesday. After that I will tackle it. Thanks for your help.

Upvote 0

No problem at all. Feel free to PM me for a phone number if needed. Oh, BTW the high pressure seals of course aren't in the gasket kit. If you talk to the techs at AV insist on a set of those seals and the installations tool. It's the least they should do.

Jking

Jking

Upvote 0

rickn, I just had the same problem the first time I used mine. The black gunk that came out is a pretty sure sign that something is seriously wrong. Since mine was new PYA sent me a prepaid label to return it. A day or two after they received it they sent me another new one. I have only used it to top off one 66cu/ft tank from 3000 psi to 4400 psi. So far so good but my fingers are still crossed. The new compressor I just received had a rough trip with Fedex. Very Luckily there was no visible damage to the compressor even though the inside of the box did have a 1 1/2" puncture hole through the foam liner. I could put my fist in the hole on the outside. The shipping box also arrived with a strap broke and the cover well terrorized. The first one that I sent back had a broken strap also but the cover was in a little better shape. Please let us know how you make out. Here is a few pics of my second new one's arrival.

Upvote 0

Thanks for all your help. I may contact you later in the week. I will call AV tomorrow, see what they say. I will post the results.

Upvote 0

rickn, I just had the same problem the first time I used mine. The black gunk that came out is a pretty sure sign that something is seriously wrong. Since mine was new PYA sent me a prepaid label to return it. A day or two after they received it they sent me another new one. I have only used it to top off one 66cu/ft tank from 3000 psi to 4400 psi. So far so good but my fingers are still crossed. The new compressor I just received had a rough trip with Fedex. Very Luckily there was no visible damage to the compressor even though the inside of the box did have a 1 1/2" puncture hole through the foam liner. I could put my fist in the hole on the outside. The shipping box also arrived with a strap broke and the cover well terrorized. The first one that I sent back had a broken strap also but the cover was in a little better shape. Please let us know how you make out. Here is a few pics of my second new one's arrival.

Wow! I remember how stout those boxes are - that took some special shipment-damaging skills.

GsT

Upvote 0

It was really daunting at first for me to tear into my compressor. Not a branded Air Venturi, but a very similar 2-stage unit made in China.

But just take your time, have a nice clean towel laid out on a solid flat surface, put the parts onto this towel in the order you remove them, and take a bunch of photos as you are taking things apart to show correct orientations, etc. This saved my azz several times!

Also, if your compressor looks similar to mine and since you will be getting into the second stage, understand that the black cylinder shown by the arrow in the pic below is filled with coolant, even after you remove the coolant lines from the head. Wrap a towel around the base of it before you lift up that collar to save yourself some coolant clean-up time. Ask me how I know!

But just take your time, have a nice clean towel laid out on a solid flat surface, put the parts onto this towel in the order you remove them, and take a bunch of photos as you are taking things apart to show correct orientations, etc. This saved my azz several times!

Also, if your compressor looks similar to mine and since you will be getting into the second stage, understand that the black cylinder shown by the arrow in the pic below is filled with coolant, even after you remove the coolant lines from the head. Wrap a towel around the base of it before you lift up that collar to save yourself some coolant clean-up time. Ask me how I know!

Upvote 0

I called Air Venturi this morning. They suggested that I ship the unit back to them, They were very nice and easy to deal with. I am now in the market for a back up. Thanks to all you helped me out.

Upvote 0

It was really daunting at first for me to tear into my compressor. Not a branded Air Venturi, but a very similar 2-stage unit made in China.

But just take your time, have a nice clean towel laid out on a solid flat surface, put the parts onto this towel in the order you remove them, and take a bunch of photos as you are taking things apart to show correct orientations, etc. This saved my azz several times!

Also, if your compressor looks similar to mine and since you will be getting into the second stage, understand that the black cylinder shown by the arrow in the pic below is filled with coolant, even after you remove the coolant lines from the head. Wrap a towel around the base of it before you lift up that collar to save yourself some coolant clean-up time. Ask me how I know!

Good notation. I wonder if a bit of compressed air into the coolant port after line removal would blow the excess coolant out before disassembly? Might save a bit of leakage below.

Upvote 0

I wonder if a bit of compressed air into the coolant port after line removal would blow the excess coolant out before disassembly? Might save a bit of leakage below.

Likely yes - good idea. I'll try it the next time I have to go into the second stage. But all is currently on hold as the parts from AliExpress I have been waiting on are now listed as "Prohibited items,destroyed in sorting center. Parcel is now destroyed" Yow! Order included gasket kits, replacement first stage valve plates and teflon seal rings, so I've got no clue as to what was prohibited. Just one of the joys in dealing with Chinese compressors which don't have vendor support.

But I'm sure glad that the OP is getting good support from the vendor on their issues!!!

Upvote 0

THM, I like you disassembly ideas it makes a lot of sense. My first thoughts on the Air Venturi was Darm it is heavy! It appears very well built and the two I have received both cutoff at about 4300-4400 psi. I thinking that is where I will leave it. Getting to 4500 psi is where the most stress is, and my newest AV is pewking light gray oil and condensation from the separator filter which is much better than the black gunk that I was getting with the first one I owned for 2 days. Still waiting for a part to hook up my Alpha filter. Not sure I trust the oil / water separator to get out all the crap. I wished they had a hose thimble on the bottom of the separator to slip a drain tube on to. Would be nice to see what anyone else has come up with. I have my OWS directly over a 4" funnel that goes down through the base the compressor is setting on. The hose goes into a 5 gallon bucket with a styrofoam top on it to contain the bleed. I had a similiar setup on my Carette but that came with two hose thimbles for the oil and water.

Upvote 0

I wonder if a bit of compressed air into the coolant port after line removal would blow the excess coolant out before disassembly? Might save a bit of leakage below.

Likely yes - good idea. I'll try it the next time I have to go into the second stage. But all is currently on hold as the parts from AliExpress I have been waiting on are now listed as "Prohibited items,destroyed in sorting center. Parcel is now destroyed" Yow! Order included gasket kits, replacement first stage valve plates and teflon seal rings, so I've got no clue as to what was prohibited. Just one of the joys in dealing with Chinese compressors which don't have vendor support.

But I'm sure glad that the OP is getting good support from the vendor on their issues!!!

Sure sorry to hear of the shipping issues. Hope you can get what you need for the repair.

Upvote 0

And when you do get everything back together ready for it’s first test run, avoid refilling it back with the coolant mix with antifreeze and distilled water you would normally use and just use plain water. It’s the act of pressurizing and holding pressure is what you’re looking for, and if all proved successful in your rebuild, just drain the water out and replace with your coolant mix.

It would suck if something else came up, which causes you to reopen everything back up and make a second coolant mess everywhere. Ask me how I know, lol!

It would suck if something else came up, which causes you to reopen everything back up and make a second coolant mess everywhere. Ask me how I know, lol!

Upvote 0

...and my newest AV is pewking light gray oil and condensation from the separator filter which is much better than the black gunk that I was getting with the first one I owned for 2 days.

From what I have read, getting a little bit of oil in the output stream is 'typical' of new compressors as they continue to break-in over the first several hours of use.

As long as it reduces over time (up to ~6 hours of run time) and doesn't increase.

I also started out with my compressors, not knowing too much and using full syn ISO 68 weight oil. I have since learned more and am now running the higher viscosity ISO 100 weight oil. This would likely also reduce some of the oil mist in the output flow, but always use the grade of oil recommended by your compressor's manufacturer.

Upvote 0

Sure sorry to hear of the shipping issues. Hope you can get what you need for the repair.

Shipping is almost a game any more, especially anything coming from OUS.

You win some, you lose some. I disputed the order with AliExpress this morning, and got an almost immediate feedback from them that my claims were accepted and that a refund would be issued. I then re-ordered everything, and we'll see how that goes. It is only a total of less than $80 I am risking, and AliExpress seems to be handling things well in support of a customer.

About an hour after my first message back from AliExpress this morning, I received notification from PayPal that I had received a full refund for the first order.

Fingers crossed on the second one...

Upvote 0

I’m on my second compressor. My first one lasted a month. It stopped building pressure and before that I was getting black sludge coming out of bleed off valve. Pyramyd Air replaced it no problem. My question is are these compressors suppose to make a slight flutter noise periodically while filling tanks. It’s like 1 second little blips. It happens 5-10 times while filling my tank. I think it might be a pressure valve but not sure.

Upvote 0

Mine made that same noise. I assumed it was normal. Hopefully someone will post a better answer for you. I ordered a Tuxing from Veradian Air to use as a back up. Hard to say how long the repair of the AV4500 will take.

Upvote 0